Call us: +86-137-2353-4866

Infusion pumps demand absolute precision and reliability in their user interfaces. The control panel is the primary point of interaction for healthcare professionals to set critical parameters such as dosage rates, volume, and infusion duration. SOUSHINE provides robust and highly reliable membrane switch solutions specifically engineered for the demanding environment of medical infusion pumps, ensuring accurate input and long-term operational integrity.

What are Membrane Switches for Infusion Pumps?

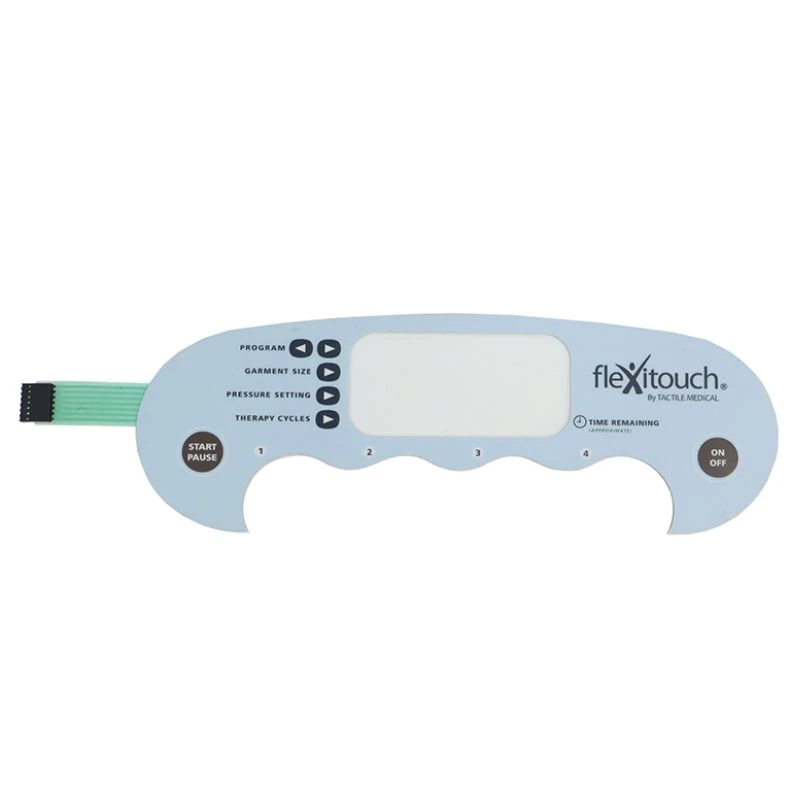

Membrane switches for infusion pump is a custom-engineered user interface component that functions as the device’s control panel. It consists of multiple layers of flexible polymer films with conductive circuits printed on them. When a specific key location on the graphic overlay is pressed, it closes a circuit, sending a precise command to the pump’s microprocessor.

For this application, the membrane switch is not just a set of buttons; it is a sealed, integrated assembly that includes the graphical interface, circuit logic, and tactile feedback mechanisms, all designed to withstand the rigors of a clinical setting.

How SOUSHINE Membrane Switches are Integrated into Infusion Pumps

The function of our membrane switches in infusion pumps is based on a reliable and sealed construction.

- Input & Actuation: A healthcare professional presses a button on the graphic overlay (e.g., ‘START’, ‘STOP’, ‘5’). This pressure flexes the top layer, pushing a conductive pad through a spacer layer to make contact with the circuit on the bottom layer.

- Signal Transmission: The contact completes a specific electrical circuit. This signal is transmitted via a flexible tail connector to the pump’s main printed circuit board (PCB).

- Sealed & Protective Design: The entire assembly is sealed at the perimeter with medical-grade adhesive. This creates a barrier that prevents fluids, cleaning agents, and contaminants from reaching the internal electronics, a critical requirement for devices that are frequently cleaned and used in sterile environments.

- Tactile Feedback: To confirm a successful keypress, metal domes can be embedded within the switch layers. These domes provide a distinct “snap” or tactile feedback, which is crucial for ensuring accurate data entry when setting infusion parameters.

Why Use SOUSHINE Membrane Switches for Infusion Pump Controls?

SOUSHINE membrane switches offer significant advantages for medical infusion pump design and manufacturing, directly addressing the core requirements of safety, reliability, and usability.

- Clinical Environment Durability: Sealed to IP65 or higher, our interfaces block fluid ingress and are built with chemically-resistant materials (PET, PC) to withstand repeated sterilization with medical-grade disinfectants.

- Long-Term Operational Reliability: Engineered for over 1 million actuations per key. The sealed construction prevents oxidation of internal silver circuits, ensuring consistent performance throughout the device’s lifespan.

- Application-Specific UI Design: We provide fully customizable graphic overlays, including precise key layouts, color matching, branding, and integrated display windows to meet your device’s exact UI/UX specifications.

- Enhanced Visibility & Feedback: Integrated LEDs for status indicators and options for full backlighting improve usability in low-light clinical settings, helping to reduce the potential for user error.

- Compact Form Factor: The inherently thin and flexible construction enables sleek, low-profile device designs, which is critical for modern portable and space-constrained medical equipment.

- Integrated EMI/RFI Shielding: Embedded shielding layers protect sensitive internal electronics from interference, ensuring stable and uninterrupted operation in electronically dense medical environments.

Display

FAQ

What is the typical operational life of a membrane switch in an infusion pump?

Our membrane switches are engineered for high-demand medical applications and are typically rated for over 1 million actuations per switch location, ensuring long-term device reliability.

Can the graphic overlay withstand harsh chemical cleaners used in hospitals?

Yes. We select overlay materials, such as chemically resistant polyester, and sub-surface printing techniques that protect the graphics and switch integrity from exposure to a wide range of medical-grade disinfectants and cleaning agents.

Can you integrate backlighting for buttons and status indicators?

Absolutely. We can embed single-point LEDs for specific status indicators (e.g., power, alarm) or utilize fiber optic layers to provide uniform backlighting for all keypad graphics, ensuring excellent visibility in all lighting conditions.

How do you ensure the switches are protected from electrostatic discharge (ESD)?

We can integrate an ESD shielding layer into the membrane switch construction. This layer is typically made of a printed silver grid or a foil layer that is connected to the device’s ground, safely dissipating any static discharge.

What is the process for developing a custom membrane switch for our new infusion pump?

Our process begins with a consultation to understand your specific technical requirements, including electrical schematics, dimensions, and environmental needs. Our engineering team then creates drawings for your approval, followed by prototyping and testing, before moving to mass production. Contact us to begin the process.