Call us: +86-137-2353-4866

Imagine you need to choose a pressure sensor for a project. Should you pick a piezo pressure sensor, a force sensing resistor, or another kind? Each sensor works in its own way and has different good points. For example, piezo pressure sensors use the piezoelectric effect to measure quick pressure changes. Picking the right sensor changes how well your system works, how reliable it is, and how much it costs. The table below shows that capacitive sensors have the biggest market share in the world. Piezoresistive sensors come next, and then piezoelectric types.

| Sensor Type | Market Share (%) |

|---|---|

| Capacitive | 23.1% |

| Piezoresistive | 19.2% |

| Piezoelectric | 15.4% |

SOUSHINE is known as a trusted partner in advanced force sensing. They offer high-quality force sensing resistor solutions for many industries.

Table of Contents

Key Takeaways

Piezo pressure sensors are great for fast pressure changes. They work well in things like microphones and jet engines. Piezoresistive sensors, like SOUSHINE’s Force Sensing Resistors, are good for steady pressure. You find them in car seats and medical devices. Capacitive sensors notice small pressure changes. People use them in touch screens and medical tools. Picking the right sensor affects how well your system works. It also affects how often you need repairs. Think about your project before you choose a sensor. Always look at the pressure range and sensitivity of a sensor. This helps you get the best results. Piezoresistive sensors last a long time and are very reliable. Piezo sensors are strong in places with lots of movement. Capacitive sensors use little power and work well in sensitive jobs. They are good for portable devices. Knowing what each sensor does helps you choose the best one. This makes your project more successful.

Piezo Pressure Sensor vs Other Types

Quick Comparison

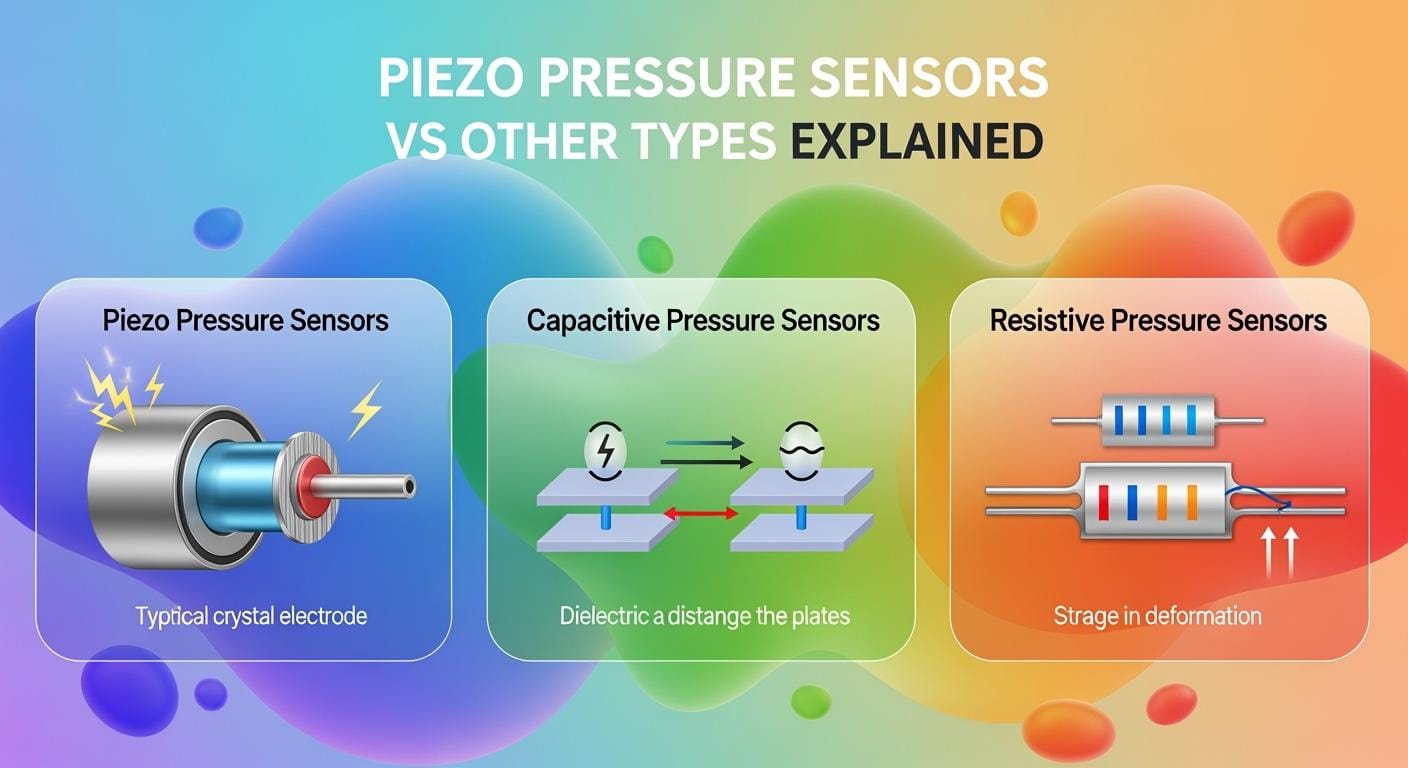

When you pick a pressure sensor, you have many options. Each type works in its own way and is good for certain jobs. The piezo pressure sensor is special because it uses the piezoelectric effect. When you press on it, it makes an electric charge. This is great for measuring fast pressure changes, like vibrations or impacts.

Let’s see how piezo pressure sensors compare to other types:

| Feature | Piezoelectric Sensors | Piezoresistive Sensors | Capacitive Sensors |

|---|---|---|---|

| Operational Principle | Makes voltage from force | Resistance changes when squeezed | Measures changes in capacitance when the diaphragm moves |

| Common Materials | Ceramic, quartz crystal | Doped silicon | Silicon, metal plates |

| Measurement Type | Measures fast, changing pressure (up to 100 kHz) | Measures steady and slow pressure | Measures steady and slow pressure |

| Sensitivity | Very sensitive, even with small changes | Sensitivity depends on resistance change | Very sensitive, not much affected by temperature |

| Applications | Used in tough places, like jet engines | Used in factories and cars | Used in phones and medical tools |

| Power Requirements | Needs little or no power | Needs outside power to work | Needs outside power |

| Complexity of Interface | More complex, needs a charge amplifier | Easier to use, often uses Wheatstone bridge | Medium complexity |

Piezo pressure sensors are best for measuring fast, changing pressure. Piezoresistive sensors, like SOUSHINE’s Force Sensing Resistors, are good for steady and slow pressure. Capacitive sensors check pressure by seeing how far plates move apart. This makes them good for slow or steady pressure.

Here are some main points to help you compare:

- Piezo pressure sensors measure quick, changing pressure. You find them in microphones, vibration testers, and jet engines.

- Piezoresistive sensors are good for steady pressure. You see them in car seats, medical tools, and machines.

- Capacitive sensors use a soft diaphragm. They check pressure by measuring the space between plates. You find them in touch screens and medical gear.

Why Sensor Choice Matters

You must pick the right pressure sensor for your job. Your choice changes how well your system works, how reliable it is, and how much care it needs. If you use a piezo pressure sensor for slow, steady pressure, it may not work well. If you use a piezoresistive sensor for fast vibrations, you might miss important data.

Picking the right sensor helps you:

- Control your system. Sensors watch pressure and help you make quick changes.

- Save energy and cut waste. The right sensor makes your system work better.

- Keep things safe. Sensors spot dangerous pressure and can set off alarms or shut things down.

If you pick the wrong sensor, your equipment could get damaged. Too much pressure can break a sensor. Calibration can change, making it less reliable and less accurate. In important systems, the wrong sensor can cause safety problems.

You should always choose a sensor that fits your needs. For example, SOUSHINE’s Force Sensing Resistors work well in cars, healthcare, and robots. They give good readings for steady and slow pressure. Piezo pressure sensors are best for places with fast pressure changes.

Sensors are important for quality control. They measure pressure, find problems, and help you keep products within limits. Good sensor choice lets you spot issues early and stop problems before they start.

Tip: Always check the pressure range, sensitivity, and where you will use the sensor before you pick one. This helps you get the best results and keeps your system working well.

You can see that picking the right sensor is important for your project. When you know the differences between piezo pressure sensors and other types, you can make better choices.

Pressure Sensor Technologies Overview

What Are Pressure Sensors?

Pressure sensors help measure how hard a gas or liquid pushes. These devices let you watch and control systems right away. When a gas or liquid pushes on the sensor, it turns that push into an electric signal. You can read this signal to know the pressure. Pressure sensors are important for safety, process control, and automation. You see them in chemical plants, oil and gas sites, food factories, and HVAC systems.

Sensor research has grown a lot in the last few decades. Different fields work together to make better sensor technology. This helps science and solves problems for people. From 2011 to 2020, sensor research grew fast and became more connected. Over 300 sensor types appeared and linked up, like ‘biosensor’, ‘fiber optic sensor’, ‘wireless sensor network’, ‘gas sensor’, and ‘optical sensor’.

Main Sensor Types

There are many kinds of pressure sensors. Each kind uses a different way to measure pressure. Here is a table that lists the main sensor types and what they do:

| Sensor Type | Measurement Principle | Key Features | Ideal Applications |

|---|---|---|---|

| Strain Gauge | Resistance changes under stress | Accurate, stable | Industrial automation, HVAC |

| Capacitive | Capacitance variation with pressure | Sensitive, low-power | Biomedical, pneumatics |

| Piezoelectric | Electric charge under force | Dynamic sensing | Vibration, combustion |

| Piezoresistive | Silicon resistance variation | Compact, precise | Automotive, process control |

| Resonant | Frequency shift detection | Ultra-stable | Aerospace, metrology |

| Optical | Light modulation by pressure | EMI immune | Subsea, hazardous areas |

| MEMS | Microstructure deformation | Miniature, integrated | Portable devices, autos |

| Diaphragm | Diaphragm deflection | Flush mount, corrosion-resistant | Viscous or sanitary media |

Piezo Pressure Sensors

Piezoelectric sensors use special materials like quartz or ceramic. When you press on them, they make an electric charge. These sensors are good for measuring quick changes, like vibrations or impacts. They work well in hard places, such as jet engines and combustion chambers. Piezoelectric sensors are very sensitive and react fast. They do not use much power, so you can use them in portable or remote devices.

Piezoresistive Sensors (FSRs by SOUSHINE)

Piezoresistive sensors, like SOUSHINE’s Force Sensing Resistors, change resistance when pressed. You use them to measure slow or steady pressure. They work well in car seats, medical tools, and robots. SOUSHINE’s FSRs give accurate readings and are easy to add to your system. You can change their shape and size for different uses.

Capacitive Sensors

Capacitive sensors check pressure by seeing how far plates move apart. When the diaphragm moves, the space between plates changes, and the sensor notes this as a pressure change. You find these sensors in medical devices and air systems. They are very sensitive and use little power. They give good readings in places with low pressure.

Other Sensor Types

There are other pressure sensor types too. Strain gauge sensors use resistance changes to check pressure. Resonant sensors look for changes in frequency. Optical sensors use light to sense pressure and work well where there is strong electromagnetic interference. MEMS sensors use tiny parts to measure pressure in small devices. Diaphragm sensors use metal or ceramic to measure pressure in thick or clean liquids.

Tip: Always pick the sensor type that fits your job. Each kind has special benefits for different pressure tasks.

Piezo Pressure Sensor Principle

Piezoelectric Effect

To understand a piezo pressure sensor, you need to know about the piezoelectric effect. When you push or press on a piezoelectric material, it makes an electric charge. This charge shows up on the outside of the material. The more pressure you use, the more charge you get. This means you can measure pressure very accurately.

Piezoelectric materials react fast to changes. When used in sensors, they give quick and exact readings. The piezoelectric effect works best when things are moving or changing. For example, you can use these sensors to watch vibrations or impacts. The sensor changes the force into a voltage signal. This signal tells you how much pressure you used. Because of this, piezoelectric sensors are great for measuring fast or changing forces.

Note: The piezoelectric effect lets you measure pressure without extra power. The sensor makes its own signal when you press on it.

Sensor Construction

Piezoelectric pressure sensors use special materials in their build. These include:

- Silicon, which makes the sensor very sensitive and strong.

- Stainless steel, which helps the sensor last in tough places.

- Ceramic, which keeps the sensor safe from chemicals and heat.

- Metal foil strain gauges, which help the sensor stay steady with high pressure.

Most sensors use a thin disk or plate made from a piezoelectric material. This disk sits between two electrodes. When you press the sensor, the material makes a charge. The electrodes pick up this charge and send it as a signal. Some sensors have extra layers to protect them from water or chemicals. This helps the sensor work well in hard places.

Piezoelectric sensors come in many shapes and sizes. Some are tiny for small spaces. Others are bigger for heavy jobs. The material and design depend on where you want to use the sensor.

Output Characteristics

When you use a piezoelectric pressure sensor, you get a signal that matches the pressure you put on it. The sensor gives you output in units like psir. You can measure very low or very high pressures, from 0.1 psig up to 10,000 psig. Most piezoelectric sensors are accurate to about 1% of their full range.

Piezoelectric sensors are special because they react very fast. You can use them to measure quick pressure changes. They are also tough and small, so they fit in many systems. The sensor makes its own signal, so you do not need outside power for sensing.

Remember, piezoelectric sensors work best for moving or changing pressure. They do not work well for steady pressure. Temperature changes can also change the readings. Still, if you need to measure fast pressure changes, these sensors are a good choice.

Tip: Use piezoelectric sensors when you want to measure vibrations, impacts, or other fast-changing forces. They react quickly and do not need extra power, so they are great for busy places.

Piezoresistive Sensor Principle

How FSRs Work

Piezoresistive pressure sensors are in many devices today. Force Sensing Resistors, called FSRs, use a simple idea. When you press an FSR, its electrical resistance changes. This helps you know how much force you use. Here is how these sensors work:

- FSRs sense pressure by changing resistance when pressed.

- The resistance gets lower as you push harder.

- This change lets you measure different pressure levels well.

You can use piezoresistive pressure sensors in many areas. They work in medical tools, robots, and sports gear. You get good readings for both light and strong touches.

SOUSHINE FSR Features

SOUSHINE’s FSRs are special piezoresistive pressure sensors. You can use them in many places, especially when you need them to last a long time. The table below shows how SOUSHINE’s FSRs compare to other piezoresistive sensors:

| Feature | SOUSHINE’s FSRs | Other Piezoresistive Sensors |

|---|---|---|

| Customizable Shapes/Sizes | Yes | Limited |

| Durability/Reliability | High | Varies |

| Low Power Consumption | Yes | Often higher |

| Ease of Integration | Simple electrical interface | May require complex setup |

You can pick the shape and size that fits your project. SOUSHINE’s FSRs are tough, so you can trust them for a long time. They are easy to add to your system. They use very little power, so they work well in portable or battery devices. These features make SOUSHINE’s FSRs a great choice for medical uses, where you need sensors that last and work well.

Output and Sensitivity

When you use piezoresistive pressure sensors, you get a clear and steady signal. The sensor gives a signal that matches the force you use. This makes it easy to watch pressure changes over time. SOUSHINE’s FSRs are very sensitive, so you can notice even small pressure changes. You can count on them to stay accurate for a long time, which is important in medical work.

In medical jobs, you need sensors that stay correct for years. SOUSHINE’s FSRs give you this kind of performance. You can use them in patient monitors, smart beds, and wearable medical tools. These sensors help you collect important data without needing to reset them often. You can feel sure your system will work well for a long time.

Tip: For medical jobs, always pick sensors that stay accurate for years. This keeps your equipment safe and working right.

You can trust SOUSHINE’s FSRs to give you the accuracy and long-lasting use you need in medical and other tough places.

Capacitive Sensor Principle

Sensing Mechanism

Capacitive pressure sensors are in many modern gadgets. These sensors work by noticing changes in capacitance when you press on them. The way they sense pressure is simple and works well:

- The sensor has two electrodes. One is a soft diaphragm that moves when you push it.

- The space between the diaphragm and the other electrode changes as the diaphragm bends.

- This movement changes the capacitance between the two electrodes.

- The sensor checks this change and turns it into a signal. This signal shows how much pressure is there.

Capacitive pressure sensors react fast to small pressure changes. You can use them to measure both low and high pressures. Many devices with mems technology use this method because it is both accurate and dependable.

Tip: Capacitive pressure sensors are perfect when you need to spot tiny pressure changes with high sensitivity.

Structure and Materials

Capacitive pressure sensors have a simple but smart design. Inside, there are two flat plates. The bottom plate does not move. The top plate is a soft diaphragm. A thin, bendy layer called a dielectric sits between the plates. When you press on the sensor, the diaphragm bends and gets closer to the bottom plate. This changes the capacitance.

Makers use special materials for these sensors. The diaphragm can be made from silicon or metal. The dielectric layer is a thin film that lets the plates move easily. Some sensors use electrodes with a fabric-like pattern to make more surface area. This helps the sensor see small changes better. Others use tooth-like shapes for the electrodes to make the sensor more sensitive and able to sense a wider range.

You will also find these sensors in many devices with mems technology. This lets you make sensors that are tiny but still very accurate.

Output Details

Capacitive pressure sensors give a signal that changes as pressure changes. The output is not the same as other sensors. You can see the difference in the table below:

| Sensor Type | Mechanism of Signal Output |

|---|---|

| Capacitive Pressure Sensor | Changes capacitance values in response to pressure. |

| Piezoresistive Sensor | Changes resistance values due to mechanical stress. |

When you use capacitive pressure sensors, you get a smooth and steady signal. This makes it easy to watch pressure changes over time. The output stays stable and is not changed much by temperature. You can trust these sensors to give correct readings in many places. Devices with these sensors often use very little power, which helps save energy.

Note: Capacitive pressure sensors are best for jobs that need steady, repeatable, and sensitive pressure readings.

Performance Comparison

Sensitivity and Accuracy

When you look at pressure sensors, you want to know how well they find small changes and how exact they are. Piezo pressure sensors are great for measuring fast pressure changes. They react very quickly, so they are good for things like checking vibrations. You get strong results when you need to watch pressure that moves fast.

Piezoresistive sensors, like SOUSHINE’s Force Sensing Resistors, are very accurate for steady pressure. These sensors have a sensitivity of 44.9 mV/V/kPa. You can trust them for jobs that need exact readings over time. Their temperature coefficient is about 0.094% FS/°C. This means they stay correct even if the temperature goes up or down.

Capacitive sensors are also very accurate and sensitive. They have a frequency pressure sensitivity of about −2.54 ppm/Pa (7.46 Hz/Pa) and a nonlinearity of less than 0.01% FS. You get a low total error band, so you can trust the numbers in careful jobs. These sensors work well in medical tools and electronics where you need high accuracy.

Tip: Pick piezo sensors for fast pressure changes. For steady and exact measurements, piezoresistive and capacitive sensors are best.

Reliability and Durability

You want your pressure sensors to last and work well in hard places. Piezo pressure sensors do well in busy spots and keep working for a long time. They do not break easily, so you can use them where things move a lot.

Piezoresistive sensors, like SOUSHINE’s, are strong and last a long time. You can use them in cars, hospitals, and robots. These sensors keep working even after many uses. Ceramic pressure sensors are also tough and do not rust. They work well in rough places, so you can trust them for a long time.

Capacitive sensors give steady readings in calm places. They do not change much with temperature and stay correct. You can use them in devices that need to last and work well.

- Piezo sensors: Good for fast jobs and rough places.

- Piezoresistive sensors: Great for steady pressure and many uses.

- Capacitive sensors: Strong for careful and steady measurements.

Cost and Value

You want to get the most for your money. Piezo pressure sensors usually cost more because they work well for fast jobs. You use them when you need speed and accuracy.

Piezoresistive sensors, like SOUSHINE’s FSRs, are accurate and last long for a fair price. You can change them to fit your needs, which is helpful. These sensors work in many fields, so you save money and get more choices.

Capacitive sensors are accurate and use little power. You find them in electronics and medical tools. They do not cost much, and you get good readings for careful jobs.

Note: Always pick a sensor that fits your budget and what you need it to do. You get the best results when you balance price, accuracy, and how long it lasts.

Application Suitability

Picking a pressure sensor depends on your job and where you use it. Each sensor type works better for certain tasks. You need to think about speed, accuracy, and the place you use the sensor.

Piezoelectric sensors are great for jobs with fast pressure changes. You see these sensors in jet engines and vibration testers. They also work in shock monitors. If you need to measure quick impacts or vibrations, these sensors give fast and correct results. They use special crystals that make electric charge when pressed. This makes them good for high-pressure and busy places. You can use them in engines or machines that move a lot. They give you good data even when pressure changes quickly.

Piezoresistive sensors, like SOUSHINE’s Force Sensing Resistors, are best for steady and long-lasting pressure jobs. You find these sensors in car seats and medical beds. They also work in robot hands. If you want to know how much force is on a seat or device, FSRs give clear and steady signals. These sensors help you watch slow or constant pressure. You can use them in hospitals to track patient movement. They also work in cars to check if someone sits down. SOUSHINE’s FSRs fit sports gear and wearable devices too. You get good readings for both light and strong touches.

Capacitive sensors are good for jobs needing high sensitivity and low power. You see these sensors in touch screens and medical tools. They also work in air pressure monitors. If you need to measure small pressure changes, capacitive sensors give smooth and steady signals. These sensors work well in clean and safe places. You can use them in labs, hospitals, or electronics. They help you track gentle touches or tiny air pressure changes.

Here is a simple guide to help you pick:

| Application Area | Best Sensor Type | Why It Fits Best |

|---|---|---|

| Fast, dynamic pressure | Piezoelectric | Handles quick changes and high pressure |

| Steady, slow pressure | Piezoresistive (FSR) | Gives stable, long-term readings |

| Sensitive, low pressure | Capacitive | Detects small changes, uses little power |

Tip: Always match your sensor to your job. Think about how fast pressure changes, how much force you need to measure, and where you will use the sensor.

When you choose the right sensor, your equipment works better and lasts longer. SOUSHINE’s FSRs are flexible and reliable for steady pressure jobs. Piezoelectric sensors are best for busy, high-pressure places. Capacitive sensors help with gentle and exact measurements. Your choice helps your project succeed.

Application Examples

Piezo Pressure Sensor Use Cases

Piezo pressure sensors are used in many factories. They are good for measuring fast and changing pressure. These sensors give quick and reliable results. They do not need moving parts, so they are simple and strong.

- You can watch pressure changes in machines.

- You can check for vibrations in engines and turbines.

- You can measure impacts in test equipment.

- You can use them to check quality on production lines.

These uses help keep machines safe and working right. You get fast feedback, so you can fix problems early.

Industrial and Dynamic Monitoring

Factories use piezo pressure sensors to find sudden pressure spikes. You see them where machines move fast or shake a lot. These sensors help you find problems early and keep things running. You can use them in labs to study how things react to force. They are also in safety systems that need to act fast.

Piezoresistive Sensor (FSR) Applications

SOUSHINE’s Force Sensing Resistors work in many places. You see them in cars, hospitals, and robots. These sensors measure steady pressure and force. They are good for long-term use.

| Industry | Applications |

|---|---|

| Automotive | Seat sensors, seat belt sensors, brake pressure sensors |

| Healthcare | Patient beds, prosthetics, wound care tools |

| Robotics | Gripper feedback, touch sensors for robot hands |

You use FSRs in car seats to check if someone is sitting. You can add them to seat belts for better safety. Hospitals use these sensors in beds to watch movement and pressure. Prosthetics use FSRs to measure force and help people move. Robots use FSRs to feel objects and control their grip. These uses make systems smarter and safer.

Automotive, Healthcare, Robotics (SOUSHINE)

You find SOUSHINE’s FSRs in many car jobs. They help cars know when someone sits or buckles up. In hospitals, you use them to track patient movement and comfort. Robots use FSRs to help machines feel touch. You can make custom sensors for each job, so they fit your needs.

Capacitive Sensor Applications

Capacitive pressure sensors are best for electronics and low-pressure jobs. You see them in many devices you use every day.

- Wearable devices

- Smartphones

- Laptops

- Gaming consoles

- Smart home devices

You use these sensors to measure light touches and small pressure changes. They help you control devices with a tap or swipe. You find them in smart watches and fitness bands. Laptops and gaming consoles use them for touchpads and buttons. Smart home devices use capacitive sensors to sense air pressure and control systems.

Consumer Electronics, Low-Pressure Sensing

You can use capacitive sensors where you need high sensitivity. These sensors give accurate readings for low-pressure jobs. You find them in medical devices that need gentle touch sensing. They are also in air quality monitors and smart thermostats. These uses make your devices easier to use and more responsive.

Choosing the Right Sensor

Decision Factors

There are a few things to think about before picking a pressure sensor. Each sensor type is best for certain jobs. The table below shows how piezoresistive and piezoelectric sensors compare for important choices:

| Factor | Piezoresistive Sensors | Piezoelectric Sensors |

|---|---|---|

| Static Pressure Measurement | Good for measuring steady pressure | Not good for steady pressure |

| High-Frequency Dynamic Pressure | Not great for fast-changing pressure | Best for fast-changing pressure |

| Self-Powered Applications | Needs outside power | Can work without extra power |

| Long-term Pressure Monitoring | Best for watching pressure over time | Signal can change over time |

| Extreme Temperature Environments | May not work well in very hot or cold places | Usually works better in tough temperatures |

| Size-Constrained Applications | Might be too big for small spaces | Can be tiny and still work well |

Think about if you need to measure steady or changing pressure. For long-term checks, piezoresistive sensors are a good pick. For quick changes, piezoelectric sensors react fast. You also need to think about power, temperature, and how much space you have.

Tip: Always choose a sensor that matches what your project needs. This helps your system work its best.

You have learned how piezo, piezoresistive (FSR), and capacitive pressure sensors are different. Piezo sensors are good for measuring quick changes. FSRs, like SOUSHINE’s, give steady and trusted results. Capacitive sensors are best for soft and low-pressure jobs.

- Choosing the right sensor makes your project work well.

- SOUSHINE’s Force Sensing Resistors are accurate and last a long time.

Check out SOUSHINE’s FSRs for smart ideas. You will get good products and helpful customer service.

FAQ

What is the main difference between piezo and piezoresistive sensors?

Piezo sensors are best for fast, changing pressure. Piezoresistive sensors, like SOUSHINE’s FSRs, work for steady or slow pressure. Each sensor is good for different jobs.

Can I use SOUSHINE’s FSRs for dynamic pressure?

SOUSHINE’s FSRs work best for steady or slow pressure. For fast, changing pressure, you should use a piezo sensor.

Are capacitive sensors good for low-pressure applications?

Yes! Capacitive sensors can measure small pressure changes. They work well in things like touch screens and medical tools.

How do I choose the right pressure sensor for my project?

Check how much pressure you need to measure. Think about how fast the pressure changes and where you will use the sensor. Pick the sensor that fits your needs. SOUSHINE’s team can help you choose the best FSR.

Do SOUSHINE’s FSRs need much power?

No. SOUSHINE’s FSRs use very little power. They are good for battery and portable devices.

Can I customize the shape or size of SOUSHINE’s FSRs?

Yes! You can ask SOUSHINE to make special shapes or sizes. This helps you fit the sensor into your project.

Where can I get support for SOUSHINE’s FSRs?

You can contact SOUSHINE by email, phone, or visit them. Their team helps you pick products, design, and gives technical support.

What industries use SOUSHINE’s Force Sensing Resistors?

SOUSHINE’s FSRs are used in cars, healthcare, robots, sports, and electronics. They help measure force and pressure in many products.