Call us: +86-137-2353-4866

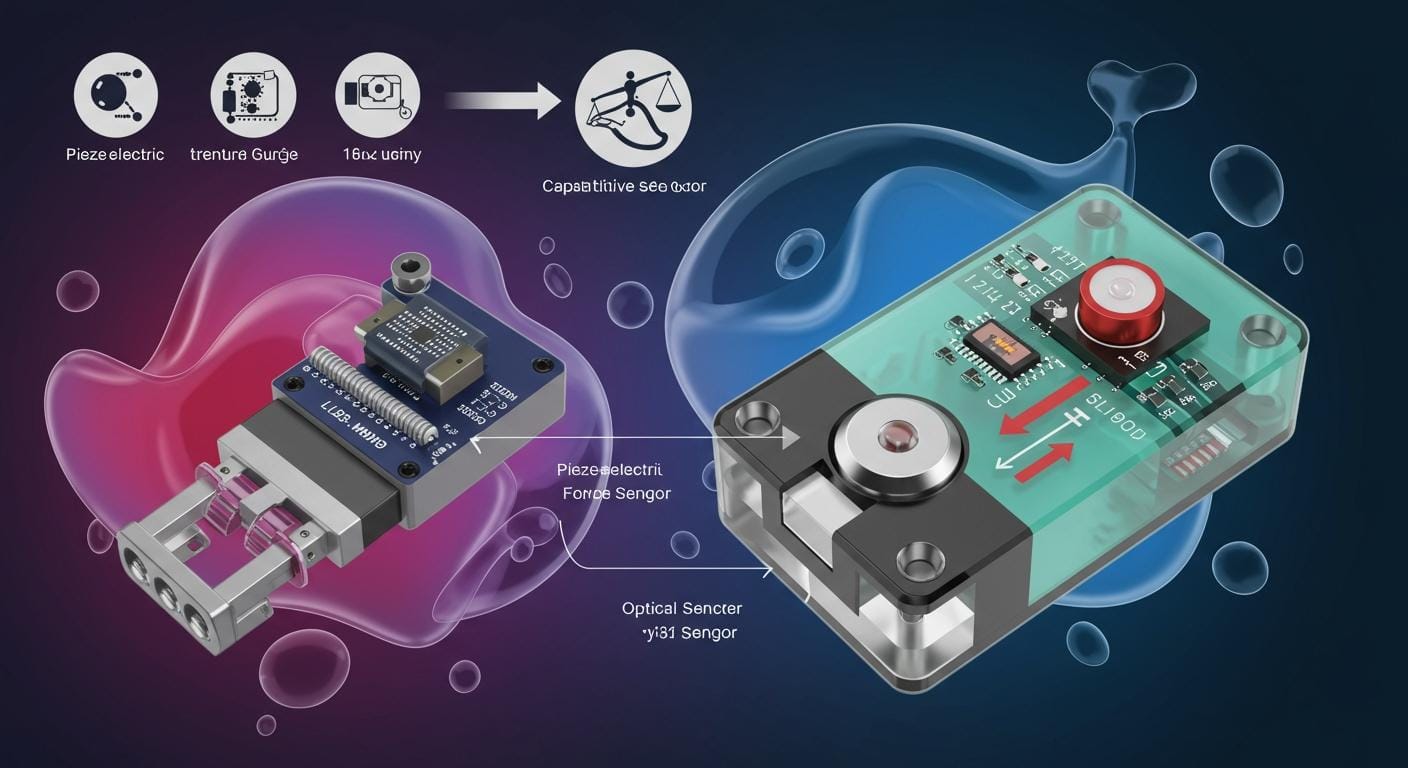

Piezoelectric force sensors are very sensitive and react fast. They work well for measuring changing forces. Most people use load cells the most around the world. But piezoelectric sensors are becoming more popular in robots and medical tools. Engineers should learn how each sensor type is different. These types include strain gauge, load cell, and force sensing resistor. Each sensor is best for certain jobs. Knowing these differences helps people pick the right sensor.

Table of Contents

Key Takeaways

Piezoelectric sensors are good for measuring fast force changes. They work well for things like checking vibrations. Strain gauge sensors are very accurate. People use them in weighing systems and to watch over buildings. Load cells are the most common force sensors in factories. They last a long time and can measure many different forces. Force sensing resistors (FSRs) do not cost much and can be used in many ways. They fit well in things like cars and medical tools. When picking a sensor, think about what you need it for. Also, look at where it will be used and how much money you have. SOUSHINE FSRs can be changed to fit special designs. This makes them good for many jobs in different businesses. It is important to check sensors like load cells often. This helps them give correct results and last longer. New technology, like IoT and new materials, is making force sensors better. These changes help sensors do more things.

Force Sensors Overview

What Are Force Sensors

Force sensors find out how much force or pressure is on something. These devices help machines notice and control changes. In factories, force sensors are very important. They help keep products safe and the same every time. They also help machines work faster and better.

Force sensors give correct data. This data helps companies save money and do things better.

Here is a table that shows what force sensors do in factories:

| Function | Description |

|---|---|

| Precision and Accuracy | Load cells and torque transducers give exact measurements. |

| Process Optimization | Measuring forces helps cut waste and make things better. |

| Safety Measures | Sensors find overloads and help stop accidents. |

| Quality Control | Watching in real time helps catch problems early and lower defects. |

Many industries use force sensors to watch, keep things safe, and work better. These sensors also help control machines and make sure products are good.

SOUSHINE makes Force Sensing Resistors (FSRs) as a main product. These FSRs measure force and pressure very well. They work great in cars, healthcare, robots, and electronics. SOUSHINE FSRs last long, cost less, and can be made for many uses.

Main Types

There are many kinds of force sensors. Each kind works in its own way and fits different jobs. The main types are:

- Load cells

- Strain gauge sensors

- Force sensing resistors

- Piezoelectric sensors

Piezoelectric Sensors

Piezoelectric sensors make electricity when force is put on them. These sensors react fast to changes in force. Many people use them to measure shaking and moving forces. They are good when you need a quick answer.

Strain Gauge Sensors

Strain gauge sensors check how much something stretches or gets smaller. When force is used, the sensor’s resistance changes. This change helps tell how much force is there. Strain gauge sensors are used a lot in building checks and weighing things.

Load Cells

Load cells are the most used force sensors in factories. They turn force from weight or pressing into an electric signal. Load cells give correct and steady measurements. Many factories use them for weighing, process control, and safety. Load cells come in many shapes and sizes for different jobs.

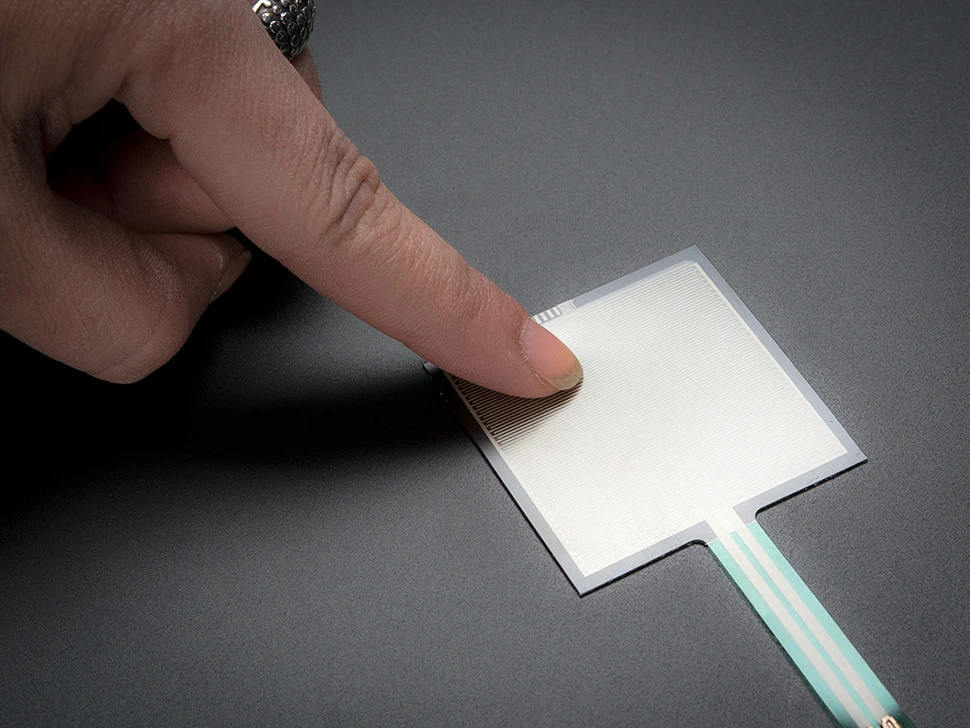

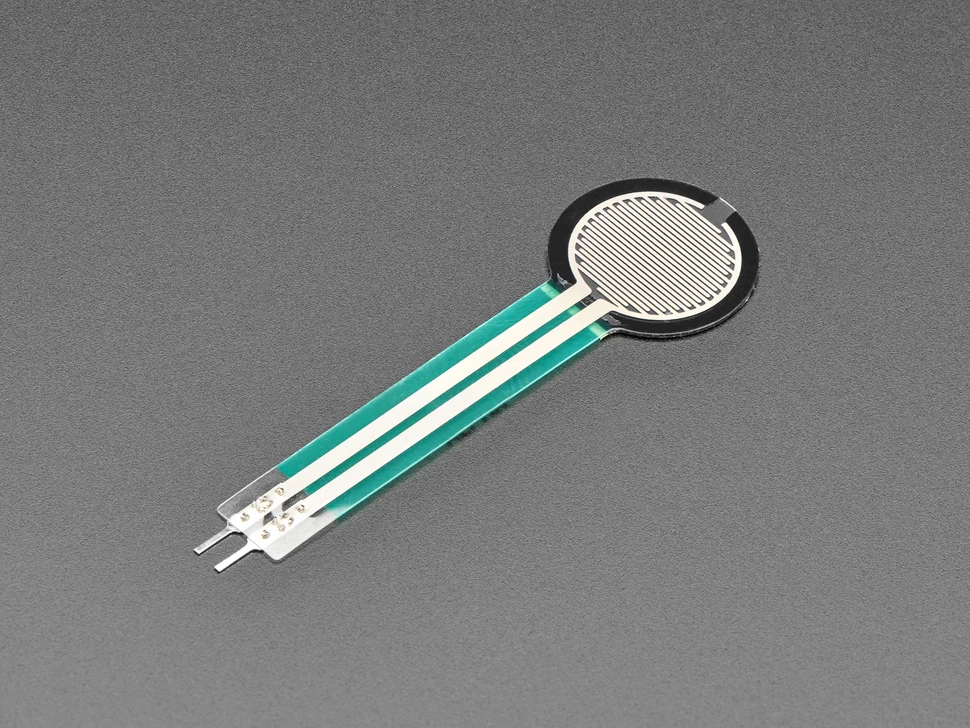

Force Sensing Resistors

Force sensing resistors, like SOUSHINE FSRs, notice changes in resistance when force is used. These sensors are thin and bendy. They fit into many products and designs. SOUSHINE FSRs work well in cars, healthcare, robots, and electronics. They are strong, use little power, and can be changed for many needs.

Operating Principles

Piezoelectric Force Sensor

Piezoelectric Effect

A piezoelectric force sensor uses special materials. These materials make electricity when squeezed or pressed. This is called the piezoelectric effect. The sensor is good for measuring fast-changing forces. It works well with vibrations or impacts. Many machines use these sensors because they react quickly. They also stay strong under pressure.

| Aspect | Description |

|---|---|

| Piezoelectric Effect | When you press piezoelectric materials, they make an electric charge. The charge amount matches the force. |

| Charge Equation | The charge made is Q = d33 * F. Here, d33 is the piezoelectric charge coefficient. |

| Sensor Types | There are flexure mode designs and other types. These can measure force, torque, or pressure. |

| Material Examples | Quartz and piezoelectric ceramics are common materials. |

| Applications | These sensors are used in accelerometers and pressure sensors. They also measure dynamic forces. |

| Limitations | They do not work as well with slow signals. This is because the charge can fade away. |

Piezoelectric force sensors often use quartz or ceramic. These materials make a charge when squeezed. The charge amount matches the force used. This helps the sensor measure things like friction or chain tension. It can also measure clutch force.

Signal Generation

A piezoelectric force sensor makes a signal in steps:

- The sensor has a piezoelectric material on a metal plate.

- When force pushes the plate, the material bends or gets squeezed.

- This makes an electric charge in the material.

- The sensor collects this charge as a voltage.

- The voltage tells how much force was used.

This process helps the sensor measure force or pressure. It can also measure acceleration. The sensor gives fast and correct data. This helps many machines and tools.

Strain Gauge

Resistance Change

A strain gauge checks how much something stretches or shrinks. The sensor sticks to the object’s surface. When the object bends or pulls, the strain gauge changes shape. This change makes its resistance go up or down.

- Strain gauges measure how much an object changes shape.

- They find changes in size or shape when under stress.

- The resistance change matches the strain amount. This helps the sensor tell how much force is there.

A strain gauge uses a Wheatstone bridge circuit. This circuit measures small resistance changes. It helps find the exact force on the object. Engineers use strain gauges for building checks. They also use them in weighing systems.

Strain gauges work by checking resistance changes from strain. The Wheatstone bridge circuit helps find these changes.

Load Cell

Mechanical Deformation

A load cell measures force by bending or stretching inside. When a load presses on it, a part inside bends or stretches. This part can be a metal bar or plate. The load cell turns this movement into an electric signal.

- Strain gauge load cells use the piezoresistance effect. When the cell bends, the strain gauge inside changes resistance.

- Hydraulic load cells use a piston in fluid. The force moves the piston and changes the fluid pressure.

- Pneumatic load cells use air pressure to measure force.

- Capacitive load cells check the distance between two plates.

- Piezoelectric load cells use the piezoelectric effect to make a signal.

- Magnetic load cells sense changes in a magnetic field.

- Vibrating wire load cells use a wire that vibrates at different speeds when stretched.

Each load cell type is good for different jobs. Most factories use strain gauge load cells. They are accurate and work well.

Force Sensing Resistor

Resistance Decrease

A force sensing resistor changes resistance when you press it. SOUSHINE FSRs have a special material that reacts to pressure. This material sits between two bendy layers. When you push on the sensor, the layers get closer together.

The main idea is called piezoresistivity. The resistance goes down as you press harder. The sensor can notice even small changes in pressure. This makes FSRs good for many uses.

- The resistive material has lots of tiny conductive particles.

- When you press, these particles move closer together.

- The area where they touch gets bigger.

- As this area grows, the resistance drops.

- The sensor sends a signal that matches the force.

SOUSHINE FSRs can measure both soft and hard presses. They give a steady signal as the force changes.

FSRs do not just turn on or off. They give many values, not just one. This helps machines know how much force is there. SOUSHINE FSRs work well in things that need to sense touch, pressure, or weight. Their simple design makes them easy to use in many shapes and sizes.

Here is a table that shows how resistance changes with force:

| Force Applied | Resistance (Ohms) |

|---|---|

| No Force | High (over 1MΩ) |

| Light Touch | Medium (10kΩ – 100kΩ) |

| Firm Press | Low (under 1kΩ) |

SOUSHINE FSRs use this idea to help cars, robots, and medical devices sense force. Their bendy design and steady output make them a good choice for many jobs.

Pros and Cons

Piezoelectric Sensors

High Sensitivity

Piezoelectric sensors can notice tiny changes in force. They react fast to pressure and vibration. Engineers use them when they need quick and exact force readings.

Dynamic Measurement

These sensors are good for measuring moving forces. They track things like impacts or shaking. Factories and labs use them to watch parts that move or change quickly.

Fragility

Piezoelectric sensors can break if not handled gently. You must be careful when putting them in or using them. Their materials might crack if they get dropped or hit hard.

Static Force Limitation

These sensors are not good for measuring steady force. The signal gets weaker if the force does not change. They work best when the force is always changing.

The table below lists the main good and bad points of piezoelectric sensors:

| Aspect | Advantages | Limitations |

|---|---|---|

| Sensitivity | Finds very small force changes | N/A |

| Dynamic Measurement | Measures fast-changing forces | Not good for slow or steady forces |

| Fragility | N/A | Can break if not handled with care |

| Static Force Limitation | N/A | Not good for measuring steady forces |

Strain Gauge

Accuracy

Strain gauge sensors are very accurate. They measure force with only a small mistake. Many companies use them when they need exact force numbers.

Drift

These sensors do not change much over time. Their readings stay the same even if it gets hotter or colder. This makes them good for long use.

Cost

Strain gauge sensors cost more than some other kinds. The cheapest ones cost about $50 to $200. The best ones cost more but last longer and are more accurate.

- Strain gauge sensors are very accurate and do not drift.

- They are good for jobs that need exact force numbers.

- They cost more than force-sensitive resistors.

| Feature | Strain Gauge Sensors | Other Technologies |

|---|---|---|

| Accuracy | ±0.1% to ±0.5% FS | Changes by type |

| Drift | <0.01%/°C | Changes by type |

| Cost | $50-$200 (entry-level) | Changes by type |

| Creep | <0.02% FS/30min | Changes by type |

| Repeatability | ±0.03% FS | Changes by type |

| Overload Capacity | 150% FS | Changes by type |

| MTBF | >100,000 hours | Changes by type |

- Creep is less than 0.02% FS in 30 minutes.

- Repeatability is ±0.03% FS.

- Temperature drift is less than 0.01% for each degree.

Load Cell

Durability

Load cells are strong and last a long time. They work well in hard places like factories or outside. Their tough build lets them handle heavy things and rough use.

Range

Load cells can measure many different force amounts. They are used for small things and big machines. Their mistake in measuring is less than 0.1%.

Maintenance

These sensors need to be checked often to work well. Workers clean and adjust them to keep them correct. Taking care of them helps them last longer.

| Sensor Type | Durability Description | Measurement Accuracy |

|---|---|---|

| Load Cells | Strong, works in tough places | Less than 0.1% mistake |

| Piezoelectric | Works in hot and rough places | ±5% mistake |

| FSRs | Handles heat and shaking | 2% to 10% mistake |

Load cells are very accurate and work well in many places. Their strength and wide range make them a top pick for measuring force.

Force Sensing Resistor

Cost-Effectiveness

Force sensing resistors like SOUSHINE FSRs are useful for many jobs. They cost less than most other sensors. This helps companies save money on big projects. FSRs are a good pick when you need lots of sensors or have little money to spend. Engineers use them in products where saving money matters.

Customization

SOUSHINE FSRs can be made in many shapes and sizes. Makers can change how thick or thin they are. This helps engineers put FSRs in small or special places. For example, a thin FSR can go in a smart watch. A bigger one can fit in a car seat. Customizing FSRs helps companies make better products for their needs.

Durability

SOUSHINE FSRs last a long time, even with lots of use. They work well when people press or touch them again and again. These sensors are used in cars, hospitals, and factories. Their strong build lets them keep working every day. Many companies trust FSRs for jobs that need tough sensors.

Low Power

FSRs do not use much power. This is good for things that run on batteries. Portable medical tools and smart gadgets last longer with FSRs. Using less power means you do not have to charge as often. SOUSHINE FSRs help make products save energy.

SOUSHINE FSRs are low cost, easy to change, strong, and use little power. These things make them a smart pick for many new products.

| Characteristic | Description |

|---|---|

| Cost-effectiveness | FSRs are cheap and good for big or low-budget projects. |

| Customization | FSRs can be made in many shapes, sizes, and thicknesses. |

| Durability | FSRs keep working after lots of use in hard places. |

| Power consumption | FSRs use little energy, so they are great for battery devices. |

Performance Factors

Accuracy

Accuracy means how close a sensor’s reading is to the real force. Load cells are very accurate and work well in labs and factories. Strain gauge sensors also measure force exactly, especially for small things. Force sensing resistors, like SOUSHINE FSRs, need careful checking to avoid mistakes. Piezoelectric sensors are good for moving forces but may not be as accurate as load cells for steady force.

Here is a table that compares accuracy and precision:

| Feature | Load Cells | Force Sensing Resistors (FSRs) |

|---|---|---|

| Accuracy | High accuracy and reliability | Needs careful reading of results |

| Precision | High precision, repeatable | Less precise, repeatability can vary |

Load cells and strain gauges are used in scales and testing because they give the same results each time. SOUSHINE FSRs are best when small changes in force matter more than exact numbers.

Sensitivity

Sensitivity shows how well a sensor finds small force changes. Piezoelectric sensors can notice tiny forces, so they are used for vibration and impact tests. Strain gauge sensors react to medium changes and fit many jobs. Force sensing resistors are very sensitive to small forces, which helps in touch buttons and grip strength tools.

The table below shows sensitivity ranges and common uses:

| Sensor Type | Sensitivity Range | Applications |

|---|---|---|

| Piezoresistive | 72 V/N | Rough measurement |

| Piezoelectric | 14.5 μN | General applications |

| Capacitive | 19.9 nN, 38.5 nN | Micromanipulation systems |

| Strain Gauge | 143 mN | Various applications |

| Force Sensing Resistor | Higher sensitivity to small forces | Touch buttons, Grip strength, Prosthetics |

SOUSHINE FSRs help robots and medical tools feel gentle touches. Their design lets them sense small changes, which is important for smart devices.

Durability

Durability tells how long a sensor lasts in tough places. Piezoelectric sensors work in trains and can handle small shakes. They also survive underground or underwater, tracking pressure and temperature. Load cells last in factories and outside, handling heavy things and rough use. Strain gauge sensors keep working in planes and weighing systems, even with temperature changes.

SOUSHINE FSRs work well in hard places. They keep working after many presses and touches. Cars, hospitals, and robots use them because they stay strong over time.

- Piezoelectric sensors watch harsh places and can power themselves.

- Load cells and strain gauges last in factories and planes.

- SOUSHINE FSRs work well where there is lots of use.

Picking the right sensor depends on how accurate, sensitive, and tough it needs to be for the job.

Temperature Stability

Temperature stability is important when picking a force sensor. Sensors work in places where it gets hot or cold. Changes in temperature can make sensors measure force wrong. Some sensors do better with temperature changes than others.

Piezoelectric sensors use quartz or ceramic materials. These materials work in hot and cold places. The sensor keeps working when the temperature goes up or down. Piezoelectric sensors are used in trains and tunnels. They also work in outdoor machines. They measure force, pressure, and vibration well. Their accuracy stays good in most temperatures.

Strain gauge sensors use thin wires or films. These sensors can drift when the temperature changes. Drift means the zero reading moves and causes mistakes. Engineers see this problem with strain gauges. They must choose the right sensor and use good methods. This helps lower drift. Strain gauges work best in places where the temperature stays steady. Big temperature changes can make them less accurate.

Load cells also have problems with temperature changes. Most load cells have strain gauges inside. When the temperature changes, the reading can change too. This happens even if the force does not change. Zero drift can cause errors in weighing or measuring force. Factories use special circuits to help load cells stay correct. These circuits fix the readings when the temperature changes.

Force sensing resistors like SOUSHINE FSRs work well in many places. Their design lets them work when the temperature changes. SOUSHINE FSRs keep measuring force and pressure. They work in cars, hospitals, and robots outside. They also work in places with changing climates.

Temperature changes can make a sensor’s baseline move. This drift can cause mistakes in force or pressure readings. Picking the right sensor and using good methods helps keep measurements correct.

The table below shows how each sensor type handles temperature changes:

| Sensor Type | Temperature Stability | Common Use Cases |

|---|---|---|

| Piezoelectric | High | Trains, tunnels, outdoor tools |

| Strain Gauge | Medium (needs compensation) | Weighing, building checks |

| Load Cell | Medium (needs compensation) | Factory scales, machines |

| Force Sensing Resistor (SOUSHINE) | High | Cars, healthcare, robotics |

Sensors with high temperature stability work better in places with lots of temperature changes. SOUSHINE FSRs help engineers make products that work well in many climates.

Applications

Piezoelectric Sensors

Vibration Monitoring

Piezoelectric sensors help machines watch for shaking. Factories use them to check motors and pumps. The sensors can spot small moves. This helps workers find problems early. They can fix things before they break. Engineers use these sensors in trains and tunnels. They measure shaking and help keep systems safe.

Dynamic Force

Piezoelectric sensors measure forces that change fast. They work well when speed is important. Car engines use knock sensors to find detonation. This helps the engine adjust for better power. Diesel fuel injectors use these sensors to control fuel flow. This helps meet strict rules. Fast solenoids use piezoelectric sensors for quick actions. They also use less energy.

The table below lists common uses for piezoelectric force sensors:

| Application | Description |

|---|---|

| Piezoelectric Knock Sensors | Find engine detonation and help engines run better. |

| Pressure Sensors | Measure quick pressure changes with fast response. |

| Diesel Fuel Injectors | Control fuel injection for better performance and less pollution. |

| Fast Response Solenoids | Move quickly with low power in small spaces. |

| Ultrasonic Cleaning | Use sound waves to clean hard-to-reach places. |

| Ultrasonic Welding | Join plastics with sound waves for strong bonds. |

Strain Gauge

Structural Monitoring

Strain gauge sensors help engineers watch buildings and bridges. They measure how much things bend or stretch. Workers use them to find weak spots. This helps stop failures before they happen. Strain gauges also help check ship hulls for strength. Power plants use them to watch stress in turbine blades.

- Car makers use strain gauges to check car frames for safety.

- Civil engineers use them to watch bridges and dams.

- Shipbuilders use them to test hulls for strength.

- Geotechnical teams measure ground stress for big projects.

- Sports equipment makers test gear to make sure it is strong.

Weighing

Strain gauge sensors measure weight in many tools. Factory scales use them to weigh products. Labs use them to test materials. These sensors give correct readings. They help keep measurements right. Sports companies use strain gauges to test equipment under stress.

Load Cell

Industrial Scales

Load cells help factories weigh things and products. Workers use them in shipping and packing. This makes sure items meet standards. The material, like steel or aluminum, affects how long they last. It also affects how accurate they are. Load cells need to be mounted right to avoid mistakes. Temperature compensation helps keep readings correct when it gets hot or cold.

- High sensitivity lets load cells find small weight changes.

- Accuracy makes sure products meet quality rules.

- Creep management keeps measurements steady over time.

- Humidity can change how load cells work, so workers watch for it.

Machinery

Machines in factories use load cells to measure force and weight. Workers put load cells in presses, mixers, and conveyors. These sensors help control machines and keep them safe. Load cells can measure force even if it is not straight. Good mounting and regular checks help load cells work well.

Load cells are important for keeping factories working right. They help workers measure, control, and improve many jobs.

Force Sensing Resistor

SOUSHINE Force Sensing Resistors (FSRs) are used in many fields. These sensors measure force and pressure. Their bendy design fits lots of products. Companies put SOUSHINE FSRs in cars, hospitals, robots, and gadgets.

Automotive

Car engineers use FSRs to make cars safer and more comfy. Seat sensors help cars know if someone is sitting. This helps control airbags and seat belt reminders. FSRs also work in seat belt and brake sensors. These sensors watch pressure and force while driving. Car makers pick SOUSHINE FSRs because they work well and are easy to use.

- Seat sensors

- Seat belt sensors

- Brake pressure sensors

FSRs help cars react fast to changes. Drivers and riders get safer trips.

Healthcare

Hospitals use FSRs in patient care tools. Beds with sensors track movement and pressure. Nurses know when a patient moves or needs help. FSRs are also in prosthetics and wound care tools. These sensors help doctors measure force during treatment.

- Patient beds

- Prosthetics

- Wound care tools

SOUSHINE FSRs give steady data to medical staff. Patients get better care with correct force readings.

Robotics

Robots need sensors to touch and feel things. FSRs let robots sense touch. Gripper feedback helps robots hold things safely. This stops damage and helps control. Engineers use SOUSHINE FSRs in robot hands and arms.

- Gripper feedback

- Touch sensors for robot hands

FSRs help robots work in factories, labs, and homes. Robots handle things gently and carefully.

Consumer Electronics

FSRs are in many electronic gadgets. Touch screens in medical devices use these sensors for quick actions. Smart watches and fitness trackers use FSRs to check grip and pressure. Game controllers and tablets use FSRs for better play.

- Touch screens in medical devices

- Smart watches and fitness trackers

- Game controllers

SOUSHINE makes FSRs in many shapes and sizes. Designers pick these sensors because they bend and use little power.

SOUSHINE gives customers many FSR choices and technical help. Their team helps engineers find the best sensor for each job.

| Application Area | Example Use Case | Benefit Provided |

| Robotics | Gripper feedback | Safe handling |

| Healthcare | Patient beds | Reliable tracking |

| Automotive | Seat sensors | Better safety |

| Consumer Electronics | Touch screens in medical devices | Fast response |

FSRs from SOUSHINE help many fields fix problems. Their design and support make them a smart pick for new products.

Choosing the Right Sensor

Application Needs

Engineers need to pick the right sensor for each job. Every sensor is best for certain tasks. Some sensors are good for fast changes. Others are better for steady forces. The choice depends on what the job needs. Robots need sensors that react quickly to touch. Factories need sensors that measure weight very accurately.

The table below shows what to think about when picking a sensor:

| Criteria | Description |

| Durability | The sensor should handle bumps and hard use. |

| Environmental | The sensor should work in dust, wet, or hot places. |

| Cost | The sensor should not cost too much and still work well. |

SOUSHINE makes Force Sensing Resistors (FSRs) for many uses. These sensors work in cars, hospitals, and electronics. Their bendy design helps engineers make things that need to feel touch or pressure.

Environment

Sensors have to work in tough places. Heat, water, and shaking can change how they work. Engineers must think about where the sensor will go. Some sensors need to be safe from water or dust. Others need to handle shaking or bumps.

The table below lists problems and ways to fix them:

| Environmental Factor | Problem | Impacts | Solutions |

| Temperature | Parts get bigger or smaller, changing how the sensor works. | The sensor might give wrong numbers or drift. | Use sensors made for hot or cold, or add covers. |

| Humidity | Water can get inside sensors and wires. | This can cause rust, noise, or wrong signals. | Use waterproof sensors, sealed wires, or covers. |

| Mechanical Vibration | Shaking makes the sensor signal jump around. | This can cause noise, mistakes, or break the sensor early. | Use soft mounts, filters, or sensors that resist shock. |

SOUSHINE FSRs work in many places like cars and hospitals. Their design lets them handle heat and wet. Engineers use these sensors inside and outside.

Budget

Money is important when choosing a sensor. Some sensors cost more because they are very accurate. Others are cheaper and good for simple jobs. Load cells for factories can be pricey. Load cells for home scales are much cheaper. Strain gauge sensors are accurate and do not drift, so they are good for long jobs. Piezoelectric sensors are good for moving force but can cost more for special jobs.

SOUSHINE FSRs are a good mix of price and how well they work. Companies use them in big projects to save money and still get good results. Their bendy design lets engineers pick the right size and shape for each job.

Engineers should think about the job, where the sensor will go, and how much it costs before picking one. SOUSHINE can help with FSRs that fit many needs.

Product Support

Product support helps engineers and companies use force sensors easily. Top brands like SOUSHINE give lots of help to their customers. Good support makes it simple to design, set up, and fix sensors. It also helps people solve problems fast.

SOUSHINE helps customers from the first idea to the finished product. Their team helps pick the best sensor for each job. They answer questions and give tips about design. SOUSHINE also helps with testing and setting up sensors. This support helps engineers avoid mistakes and save time.

Many companies need sensors in special shapes or sizes. SOUSHINE lets customers change how their sensors look or fit. Their team listens to what customers want and changes the design. This makes it easy to use sensors in new products or small spaces.

Quality is important for every sensor. SOUSHINE checks each sensor before sending it out. Their team uses strict rules and tests every sensor. This makes sure each sensor works well and lasts long. Customers trust SOUSHINE because their sensors meet high standards.

Packaging is also part of product support. SOUSHINE gives different ways to pack sensors. Companies can pick the best way to ship or show their sensors. Good packaging keeps sensors safe and helps brands look better.

The table below shows the main types of support from top brands:

| Type of Support | Description |

| Professional Design | Working with customers to make new products. |

| Production Standard | Using strict rules for every sensor. |

| Rigorous Testing | Testing sensors to make sure they work well. |

| Diversity Packing Ways | Different packaging choices to help brands stand out. |

Customers get many good things from SOUSHINE and other top brands:

- Good prices and strong quality

- Many ways to change sensors

- Careful checks for good working sensors

- Full help from start to finish

Product support helps engineers fix problems and make better products. SOUSHINE gives strong help at every step, from design to delivery.

Engineers should pick companies that give full support. Good support means fewer mistakes and better results. SOUSHINE stands out by helping with design, testing, and packaging. Their team answers questions and gives advice. This makes it easy to use force sensors in cars, healthcare, and robots.

Picking a sensor is not just about the product. Support is important too. SOUSHINE helps customers get the most from their sensors. Their help saves companies time and money. Engineers can trust SOUSHINE to help at every step.

Future Trends

Piezoelectric Materials

New piezoelectric materials are changing how sensors work. Scientists are making materials that collect energy from people moving. These materials help make sensors for things you can wear. Wearable technology needs sensors that do not need batteries. Some new sensors use energy from walking or moving your arm. This makes sensors work better and be more useful every day.

- New materials let sensors get energy from movement.

- Wearable gadgets use these materials for smart sensing.

- Better designs help piezoelectric sensors work better.

These changes help sensors last longer and fit in more things. SOUSHINE watches these trends and tries to use new materials in future products.

IoT Integration

Force sensors now connect to the Internet of Things, or IoT. This helps people and machines get data right away. Sensors use Wi-Fi, Bluetooth, and other wireless ways to send data fast. Factories and homes use these sensors to watch force and pressure. The data goes to the cloud or computers for checking.

| Benefit/Technology | Description |

|---|---|

| Enhanced connectivity | Sensors use Wi-Fi and Bluetooth for real-time data. |

| Data analytics | Companies use data to make better decisions. |

| Interoperability | Different sensors work together in one system. |

| Miniaturization | Small sensors fit in many devices. |

| Wireless communication | Zigbee and LoRaWAN help with remote monitoring. |

| Cloud computing | Stores and processes sensor data. |

| Edge computing | Processes data close to the sensor. |

| Artificial intelligence | AI finds patterns and automates tasks. |

| Blockchain | Keeps sensor data safe and secure. |

SOUSHINE makes IoT-ready FSRs for many uses. Their sensors help companies collect and use data for better results.

Emerging Technologies

New technology is changing how force sensors work. Better materials make sensors more exact and strong. Smaller sensors can go in more things, like watches and cars. IoT lets sensors share data and work together. Artificial intelligence and big data help people understand sensor data and make smart choices.

| Emerging Technology | Influence on Sensor Selection and Application |

|---|---|

| Advancements in Materials | Sensors become more precise and durable. |

| Miniaturization | Small sensors work in many new places. |

| IoT Integration | Sensors connect and share data easily. |

| AI and Big Data Analytics | Data from sensors helps automate and improve decisions. |

SOUSHINE keeps working on new ideas. The company follows new trends and tries to give the best sensing solutions to its customers.

Piezoelectric sensors can measure quick force changes. Strain gauge and load cell sensors are very accurate for steady force. SOUSHINE FSRs come in many shapes and fit lots of products.

- Think about what the job needs.

- Look at where the sensor will be used.

- Compare prices and help from the company.

- Try out sensors before picking one.

SOUSHINE FSRs work well and are easy to change for different jobs.

FAQ

What is a piezoelectric force sensor?

A piezoelectric force sensor has special materials inside. These materials make electricity when you press them. The sensor can measure fast changes in force. Engineers use it to find vibrations and impacts.

How does a force sensing resistor (FSR) work?

An FSR gets less resistance when you push on it. The sensor sends out a signal that matches the pressure. SOUSHINE FSRs help measure touch and grip in many gadgets.

Where do engineers use SOUSHINE FSRs?

Engineers put SOUSHINE FSRs in cars, hospitals, robots, and electronics. These sensors help check seat pressure, patient moves, robot grip, and touch screens.

What makes load cells different from other force sensors?

Load cells have a metal part that bends when pressed. The sensor changes this bend into an electric signal. Factories use load cells to weigh things and control machines.

Can force sensors work in hot or cold places?

Many force sensors, like SOUSHINE FSRs, work in hot and cold. Some sensors need extra covers to stay safe. Engineers pick sensors based on where they will go.

Why do engineers choose FSRs for smart devices?

FSRs use little energy and fit in tight spots. They help smart watches, fitness bands, and medical tools sense touch and pressure.

How do engineers pick the right force sensor?

Engineers think about the job, place, and money. They compare how accurate, tough, and helpful each sensor is. SOUSHINE helps match FSRs to each project.

Do force sensors need maintenance?

Some sensors, like load cells, need regular checks. Others, like SOUSHINE FSRs, last long with little care. Engineers follow rules to keep sensors working well.