Call us: +86-137-2353-4866

You now see fast changes in piezoelectric load sensor technology as more people want them. The market will be worth USD 38.40 billion in 2025. It will grow at 7.7% each year. New ideas in wearable biosensors, machine learning, and wireless data sharing bring new ways to sense force. You get help from these trends as you look for better accuracy and real-time data. SOUSHINE is leading this progress with advanced force sensing resistor solutions for your changing needs.

Table of Contents

Key Takeaways

- The piezoelectric load sensor market will be worth USD 38.40 billion by 2025. It will grow by 7.7% every year.

- Flexible piezoelectric sensors are getting more popular in electronics and wearables. This makes them useful in more ways.

- Wireless connectivity lets sensors send data from far away. This helps people watch and control things better.

- New materials, like lead-free ones, make sensors safer for the environment. These materials also help sensors work better.

- Real-time data from piezoelectric sensors helps stop machines from breaking. It also helps save energy.

- Automation and smart technologies make more people want piezoelectric sensors in many industries.

- Nanomaterials make sensors smaller and more sensitive. This lets them work in very precise jobs.

- SOUSHINE’s Force Sensing Resistors are very accurate and use little power. This makes them great for many different uses.

Key Trends in Piezoelectric Load Sensor

Market Growth and Expansion

The piezoelectric load sensor market grows fast in 2025. The market value reaches USD 38.40 billion. It goes up by 7.7% every year. Many industries help this growth, like aerospace, healthcare, and automotive. North America is ahead because it has strong factories. Asia Pacific is next with quick changes in cars and energy-harvesting.

These trends help you as more industries use piezoelectric sensor solutions. Smart sensors are wanted by many people. Piezoelectric materials are found in lots of new gadgets. Energy harvesting is popular, especially for wearables and IoT devices.

Here is a table that shows the main trends and how they help adoption:

| Trend Description | Impact on Adoption |

|---|---|

| Advancements in AI technology | Sensors get more accurate and respond faster for health and automation. |

| Increasing demand for smart sensors | More piezoelectric materials are used in aerospace and defense. |

| Growth of energy harvesting applications | Piezoelectric materials give power to wearables and IoT devices. |

Flexible piezoelectric sensor solutions are now the most valuable in the tactile sensor market. More people use flexible piezoelectric sensor devices in electronics and wearables.

Technology Shifts in 2025

Big changes happen in piezoelectric sensor design and use. Automation and robotics grow in car factories. You need sensors that measure force very accurately. Smaller sensors fit into tiny devices, which helps medical and wearable tech.

Wireless communication gets better. You can check sensors from far away and get data right away. Lead-free piezoelectric ceramics are made. Organic materials work better now. New mixes with stronger piezoelectric coefficients are created.

Flexible piezoelectric sensor devices are used more often. You put them in bendable electronics and wearables. Small energy harvesters change how sensors get power. Piezoelectric materials turn movement and pressure into electricity. You collect energy from shaking, moving, and pressing in factories.

Low-power IoT devices work by themselves. You do not need to change batteries or fix them often. Wireless sensor networks get bigger because of these changes.

These trends change the future of piezoelectric load sensor technology. You use flexible piezoelectric sensor devices and small energy harvesters in more places. You trust piezoelectric sensor solutions for better results and to save energy.

- Here are the trends you see:

- Flexible piezoelectric sensor use grows in electronics and wearables.

- Small energy harvesters give power to industrial sensors.

- Wireless sensor networks get bigger and need less fixing.

- Lead-free and better piezoelectric materials make sensors work better.

You keep up by following these piezoelectric sensor technology trends. You pick solutions that give you accuracy, flexibility, and save energy.

Flexible Piezoelectric Sensor Trends

Material Innovations

New materials help flexible piezoelectric sensors work better. These changes let you use sensors in more places. Sensors last longer because of these new materials. The table below shows the main material changes:

| Innovation Type | Description |

|---|---|

| Flexible Piezoelectric Materials | Materials keep piezoelectric properties when bent or stretched. |

| Substrate and Electrode Design | Designs let sensors bend and stretch without losing performance. |

| Nanostructured Sensors | Nanostructures make sensors more flexible and sensitive. |

| Fabrication Techniques | New ways to make sensors, like printing and roll-to-roll processing. |

| Integration with Flexible Electronics | Ways to combine sensors with other flexible parts for full systems. |

Biocompatible Materials

Biocompatible materials are used in flexible piezoelectric sensors for health. These materials work well with the human body. You can put sensor patches on skin or inside the body. Polyvinylidene fluoride and hydrogels are common choices. They help measure body signals safely. You see these materials in wearable health monitors and smart patches.

Nanomaterials

Nanomaterials change how flexible piezoelectric sensors are made. You add nanowires and nanoparticles to the sensor. This makes sensors more sensitive and flexible. Nanostructured sensors bend and stretch easily. You get better results in health and industry. Nanomaterials also make sensors smaller and lighter.

New material mixes, like piezoelectric composites and hydrogels, make sensors more sensitive and tough. These changes let sensors work in hard places. Composites like PZT-5A with silicone resin fit curved surfaces. You have more choices for placing sensors in different places.

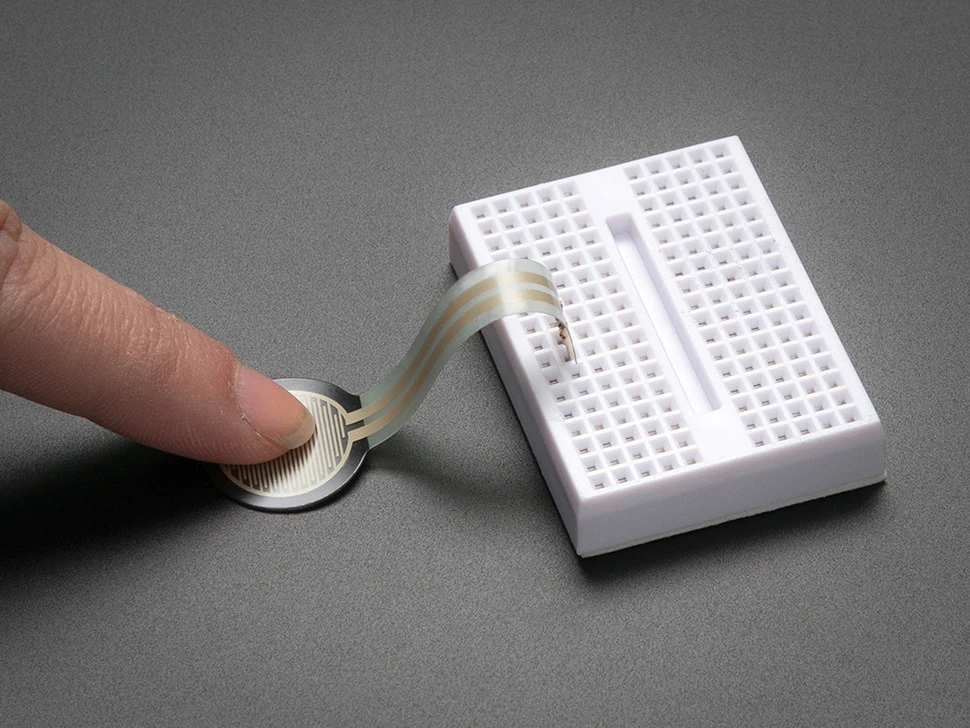

Wearable and Stretchable Applications

Flexible piezoelectric sensors are used in many wearable and stretchable things. These sensors go into electronic skins, tattoos, and smart clothes. You use them for health checks and human-machine interaction. Sensors track movement, pressure, and touch. You get real-time data to help make quick choices.

Sensors use materials like polyvinylidene fluoride and conductive hydrogels. These materials help build thin, light, and energy-saving sensors. You see sensors in smartwatches, fitness bands, and medical patches. The market for wearable piezoelectric sensors grows fast. In 2025, over 100 pilot IoT sites use sensors for traffic and energy-neutral work. In 2024, 300 research implants use sensors to check blood pressure. In 2023, over 8,000 wireless sensor nodes shipped to new places.

You follow these changes to use flexible piezoelectric sensors in more ways. You get better health data, safer machines, and smarter devices. Flexible piezoelectric sensor technology helps shape the future of sensing.

Integration with IoT and Smart Systems

Real-Time Data and Analytics

Piezoelectric sensor technology now works with IoT and smart systems. These sensors collect data from machines, cars, and medical tools. You get feedback right away, so you can act fast. Flexible piezoelectric sensor solutions help you track force, pressure, and movement in many places.

Piezoelectric sensor networks help you watch equipment and find problems early. This stops breakdowns and keeps machines working. Analytics help you save energy and meet your goals. Flexible piezoelectric sensor devices let you check energy use and find ways to spend less.

Here are the main benefits of real-time data and analytics with piezoelectric sensor systems:

- You stop machines from breaking by finding problems early.

- You make work faster by fixing slow spots in your process.

- You save energy by tracking use and finding ways to cut back.

- You help machines last longer by watching how they are used.

- You spend less money by using predictive maintenance and running things better.

Flexible piezoelectric sensor devices are used in smart factories, hospitals, and homes. You see new ways piezoelectric sensor technology helps you get better results with less work.

Wireless Connectivity

Piezoelectric sensor devices can connect to wireless networks. Flexible piezoelectric sensor solutions send data from far away. You set up sensor networks in factories, cars, and smart buildings. You get updates without wires or checking by hand.

Wireless connectivity trends make piezoelectric sensor systems stronger. New designs, like cantilever beams, help sensors work better. Optimization methods help get more energy from movement and pressure. Wireless sensor networks run on energy from piezoelectric sensor devices.

Flexible piezoelectric sensor devices help build big networks. You can watch machines, track health, and control systems from anywhere. Piezoelectric sensor technology helps you make smart choices with real-time data.

Here is a table that shows how you use piezoelectric sensor devices with IoT and smart systems:

| Application Area | How You Use Piezoelectric Sensor Devices | Trends You See |

|---|---|---|

| Industrial Automation | Watch machines, predict failures, save energy | Growth in smart factories |

| Healthcare | Track patient movement, check vital signs | Rise in wearable health tech |

| Consumer Electronics | Control devices, measure touch and pressure | Expansion of smart gadgets |

| Smart Buildings | Watch energy use, control lighting and climate | More connected systems |

You follow trends in piezoelectric sensor technology to build smarter, safer, and more efficient systems. Flexible piezoelectric sensor devices help you connect, watch, and control your world.

Miniaturization and Precision

MEMS and Compact Designs

Smaller piezoelectric sensors are now used in more places. You can put them in medical tools and smart wearables. They also fit inside machines. MEMS help make these sensors tiny and useful. These systems use small parts to measure force and movement.

New nanomaterials help make sensors even smaller. Carbon-based materials like graphene are now common. Carbon nanotubes are also used in flexible piezoelectric sensor designs. These materials make sensors very sensitive. Lead-free piezoelectric materials are used more now. Zinc oxide nanowires and barium titanate nanostructures are examples. These materials help sensors change energy at a tiny scale.

Energy harvesting is a new trend for piezoelectric sensors. Your sensor can work without needing outside power. It collects energy from movement or pressure. This powers the sensor by itself. You see this in many new sensor products. These sensors are more reliable and easy to use in hard places.

- Here are some important miniaturization trends:

- Nanomaterials make sensors smaller and better.

- Carbon-based materials help build tiny, sensitive sensors.

- Lead-free piezoelectric materials make energy conversion safe.

- Energy harvesting lets sensors run without extra power.

You can now use flexible piezoelectric sensors in more places. These trends help you meet new needs in health and smart devices.

High-Precision Sensing

You want your piezoelectric sensor to be very accurate. High-precision sensing is now a big trend. Flexible piezoelectric sensors can measure tiny changes in force. This helps in medical and industrial work.

Designs are better now and give more repeatable results. You can trust your sensor to work the same every time. The sensor responds faster now. You get real-time data for quick choices.

Here is a table with current sensor benchmarks:

| Metric | Value |

|---|---|

| Linearity | < 0.06% |

| Repeatability Error | < 0.36% |

| Dynamic Response | High |

| Measurement Range | Improved due to design |

You see these numbers in new flexible piezoelectric sensors. These trends help you use sensors where accuracy is important. You can use them in robots, medical devices, and smart electronics.

You follow these trends to get the best results. Miniaturization and high-precision sensing shape the future of flexible piezoelectric sensors.

New Materials in Piezoelectric Sensor

Lead-Free Options

There are new changes in piezoelectric sensor materials. Many companies now pick lead-free choices. These materials help you make sensors that are better for the environment. Old piezoelectric sensor designs use PZT, which has lead. Lead is harmful and makes recycling hard. You want safer options for your flexible piezoelectric sensor projects.

You can find many lead-free piezoelectric sensor materials today. These choices give you good results and keep things safe. Here are some lead-free materials people use most:

- Ionix XLF580 works well when it is very cold. It does not change much with temperature compared to PZT.

- BaTiO3 is a common lead-free piezoelectric sensor material. You use it for many sensor designs because it works well.

- Na0.5Bi0.5TiO3 is being studied a lot now. It shows good piezoelectric sensor properties.

- Bismuth Sodium Titanate (BNT) is used more in flexible piezoelectric sensor projects. It follows environmental rules and works well.

BNT ceramics are growing fast. The market for BNT lead-free piezoelectric sensor materials will go from USD 141 million in 2025 to USD 744.3 million by 2035. This means people want safer and greener piezoelectric sensor solutions.

| Material Composition | Properties and Applications |

|---|---|

| BaTiO3 | Well-known lead-free piezoelectric material with good results. |

| Na0.5Bi0.5TiO3 | Shows good piezoelectric sensor properties, studied a lot. |

| Bismuth Sodium Titanate (BNT) | Follows rules and works well in flexible piezoelectric sensor projects. |

You pick lead-free piezoelectric sensor materials to follow new rules and lower risks. These changes help you make flexible piezoelectric sensor devices that last longer and stay safe.

Composite Structures

You also see new ideas in composite structures for piezoelectric sensor design. Composite materials mix different things to make sensors stronger and more sensitive. You use these structures in flexible piezoelectric sensor projects for better results.

Composite structures let you put piezoelectric sensor parts inside during making. You watch curing steps and measure strain with fiber Bragg grating (FBG) sensors. You find damage early and keep your flexible piezoelectric sensor systems working well.

| Method | Description |

|---|---|

| Embedded Sensors | PZT sensors put inside during making to watch curing steps. |

| Strain Measurement | FBG sensors used to measure strain in resin. |

| Damage Identification | Tests done to see how well damage can be found after curing. |

You use composite structures for real-time checks and fixing before problems happen. These changes help you spot damage early and keep your piezoelectric sensor systems working.

| Aspect | Description |

|---|---|

| Monitoring | Use SHM technologies to check how composite structures work in real time. |

| Damage Detection | Find damage early with new sensor technologies. |

| Predictive Maintenance | Use SHM systems to help fix things before they break. |

You see that new materials and composite structures make piezoelectric sensor devices better for the environment. You use lead-free and advanced composites to build flexible piezoelectric sensor solutions that last longer and work better. These changes help shape the future of piezoelectric sensor technology and help you meet new safety and sustainability standards.

| Environmental Consideration | Description |

|---|---|

| Lead content in traditional PZT materials | Old PZT materials have lead, which is bad for the environment. |

| Energy consumption during manufacturing | Making piezoelectric materials uses a lot of energy and affects the environment. |

| Disposal and recycling of PZT components | Throwing away or recycling PZT parts is hard and hurts the environment. |

| Development of lead-free alternatives | Scientists look for lead-free materials that are safer and still work well. |

You follow these changes to pick flexible piezoelectric sensor materials that help you reach your goals for strong, sensitive, and green sensors.

Industry Applications and Innovations

Automotive and Aerospace

Many new things are happening in cars and planes. These industries use piezoelectric sensor technology to make things safer and work better. SOUSHINE’s Force Sensing Resistors are important in these areas. You find these sensors in airbag systems. They check if someone is sitting in the seat and help airbags work right. This keeps people safe. Sensors are also in door seals. They watch pressure to stop leaks and lower noise. Car seats use sensors to see how the driver sits. This helps drivers feel more comfortable. Electric cars use sensors to check battery pack pressure. This keeps batteries safe when shipping and using them.

Planes use piezoelectric sensor solutions for tough jobs. These sensors work well in hard conditions. You trust them for flight control and checking if parts are strong.

| Sector | Application Description | Purpose |

|---|---|---|

| Automotive | Sensors in airbags check seats and help airbags work right. | Airbags use the right force for each person. |

| Automotive | Sensors in door seals watch pressure. | Stops leaks and makes cars quieter. |

| Automotive | Sensors in seats check how drivers sit. | Makes driving more comfortable. |

| Automotive | Sensors check battery pressure in electric cars. | Keeps batteries safe when moving and using them. |

| Aerospace | Sensors work well in tough places. | Makes sure sensors last and work in planes. |

SOUSHINE FSRs give important data to make cars and planes smarter and safer. The technology helps sensors work well and last long in busy places.

Healthcare and Medical Devices

Healthcare is using more piezoelectric sensor technology. You use flexible piezoelectric sensor devices in medical tools and wearables. These sensors help watch how patients move. The market for piezoelectric sensor technology in healthcare will be USD 2.687 billion in 2025. By 2030, it will grow to USD 3.625 billion.

| Year | Market Size (USD) | CAGR (%) |

|---|---|---|

| 2025 | 2.687 billion | N/A |

| 2030 | 3.625 billion | 6.17 |

Flexible piezoelectric sensor solutions help you check vital signs and movement. You see these sensors in smart patches and medical wearables. They give real-time data for patient care. SOUSHINE FSRs help by giving good and exact sensing for medical devices.

Robotics and Consumer Electronics

You see flexible piezoelectric sensor technology in robots and electronics. These trends change how you use machines and devices. Robots use flexible piezoelectric sensor devices to watch movement. This helps robots move better. Electronics use sensors for touch feedback and motion sensing. You find these sensors in phones and wearables.

| Aspect | Description |

|---|---|

| Sensor Type | Flexible piezoelectric sensors |

| Application | Used to watch robot movement and wearable tech |

| Material Used | Polyvinylidene fluoride (PVDF) |

| Key Findings | Better beta crystal orientation makes sensors work better; sensors can be made cheaply; materials are good for the environment. |

| Implications | Used for health checks, diagnostics, and robots. |

New materials like PVDF make piezoelectric sensors work better. A new ceramic material costs less and works well for robots. It bends easily and works the same with voltage. This makes it good for robots and electronics.

Tip: You can use flexible piezoelectric sensor devices to build smarter robots and better gadgets.

SOUSHINE FSRs help make these changes happen. They support new ideas in cars, healthcare, robots, and electronics. You use piezoelectric sensor technology to make things safer, smarter, and work better.

Regulatory and Environmental Trends

Compliance Updates

There are new rules for piezoelectric sensor technology. These rules change how you design and use these devices. You must follow strict standards for materials and data. The table below lists the main rules for making and using these sensors:

| Regulatory Aspect | Description |

|---|---|

| FDA Approval | Many medical piezoelectric sensor devices are Class II. You need 510(k) clearance and must show they work like older devices. |

| EU MDR | You must meet strong rules for biocompatibility and risk management for implantable piezoelectric sensor devices. |

| Material Compliance | RoHS and REACH rules limit some materials. You may need to change piezoelectric sensor designs or use new materials. |

| Data Security | GDPR and CCPA set rules for data handling. You must get consent and use only the data you need for networked piezoelectric sensor systems. |

You follow these rules to keep your devices safe and legal. You check which rules fit each sensor application. You change your designs to meet new standards. More products are tested for safety and data security.

Sustainability Initiatives

More companies want piezoelectric sensor technology to be greener. These trends help you protect the environment. Piezoelectric harvesting technology lets you use energy that would be wasted. This energy powers your sensor devices. Your applications become cleaner and more efficient.

XIDIBEI is a leader in energy harvesting. Their sensors turn vibrations into electricity. This powers IoT systems and lowers battery use. More sensors now run on harvested energy.

You also see these trends at work:

- You build new labs to test sensor materials and uses.

- You work with other companies and schools to find better solutions.

- You design products that use miniaturization, energy harvesting, and AI.

You follow these trends to make sensors last longer and use less energy. You pick materials that are safe and easy to recycle. More applications help lower waste and save power.

By following new rules and using green ideas, you help shape the future of piezoelectric sensor technology. You make your devices safer, smarter, and better for the planet.

Market Drivers and Challenges

Growth Catalysts

Many things help the piezoelectric sensor market grow in 2025. Factories use more automation now. Machines work better with piezoelectric sensor systems. Smart technologies are used in lots of industries. These smart systems use piezoelectric sensor devices to collect data. They also help control machines. People want to save money and work faster. Piezoelectric sensor solutions help with these goals.

- More factories use automation.

- Smart technologies are added to many places.

- People want to save money and work better.

Piezoelectric sensor products are used in cars and medical devices. They are also found in smart buildings. Robotics and consumer electronics use more piezoelectric sensor devices. These trends help people fix problems and do their jobs better.

Technical and Cost Barriers

There are some problems when using piezoelectric sensor technology. It is hard to use piezoelectric sensor devices everywhere because rules are different. You may need to change your systems for each place. Piezoelectric sensor products cost more than other sensors. You have to think about your budget before you buy them.

It is hard to know how well a piezoelectric sensor turns energy into power. This makes it tough to pick the best one for your needs. Some piezoelectric sensor materials have toxic things like lead. You must follow strict rules to keep your devices safe, especially in Europe.

People look for new materials and designs to fix these problems. They want to meet rules and spend less money. By following new trends, you can stay ahead and do better in your work.

Leading Products and Companies

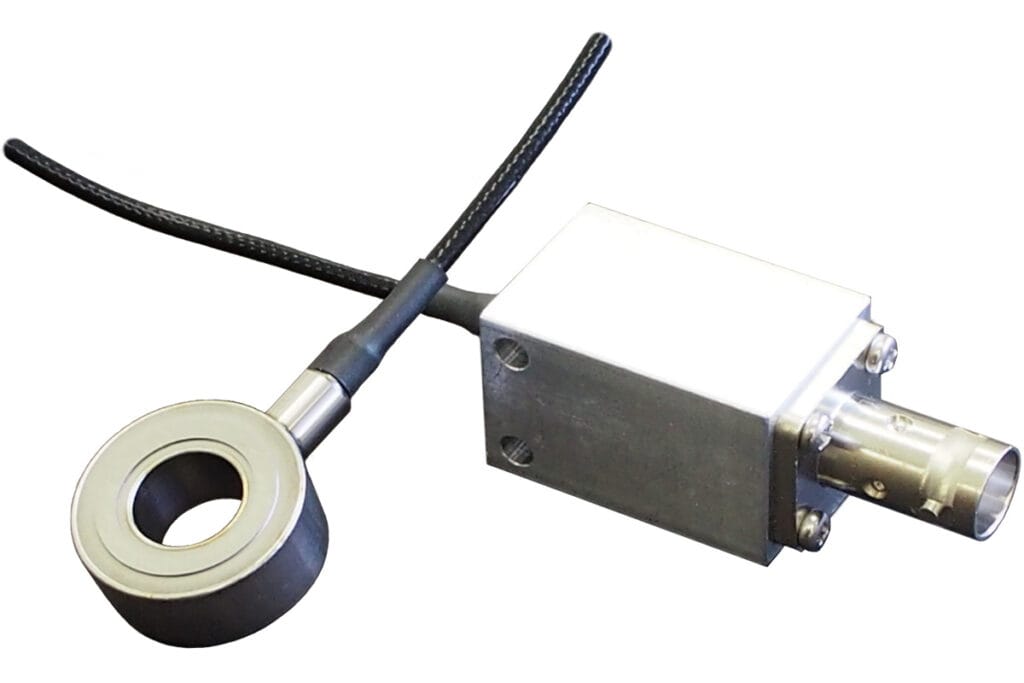

SOUSHINE Force Sensing Resistors

There are many new changes in the piezoelectric sensor market. SOUSHINE is special because of its Force Sensing Resistors. You use these piezoelectric sensor devices in lots of industries. They give you very good accuracy and last a long time. You can change these piezoelectric sensor solutions for your project. These piezoelectric sensor devices use little power, so you save energy. It is easy to add SOUSHINE piezoelectric sensor products to your systems.

You pick SOUSHINE Force Sensing Resistors when you want piezoelectric sensor devices that work well and are easy to use.

Here is a table that shows how SOUSHINE’s FSRs are different from other piezoelectric sensor products:

| Feature | SOUSHINE’s FSRs | Competitors’ FSRs |

|---|---|---|

| Accuracy | Superior | Varies |

| Durability | High | Moderate |

| Customization | Extensive | Limited |

| Low Power Consumption | Yes | Varies |

| Ease of Integration | Simple | Complex |

SOUSHINE piezoelectric sensor devices give you more options and better results. You use these piezoelectric sensor solutions in cars, medical tools, robots, and electronics. You follow piezoelectric sensor technology trends by picking products that last and work well.

Other Key Innovators

Other companies also lead in piezoelectric sensor technology. These companies make new piezoelectric sensor products and start new trends. TDK Corporation and Honeywell are big names in the piezoelectric sensor market.

Here is a table with new products from top companies:

| Company | Product Description | Launch Date |

|---|---|---|

| TDK Corporation | Made two new piezo actuators, RoHS-compatible lead zirconate titanate (PZT) | July 2023 |

| Honeywell | Bought Invensys Sensor Systems to grow its sensor business in medical markets | Aug 2022 |

You watch these changes in piezoelectric sensor development. You see new piezoelectric sensor products with better features. You use these piezoelectric sensor devices for new needs in automation, healthcare, and electronics.

You stay ahead by learning about new piezoelectric sensor products and following market trends.

SOUSHINE and other companies help shape the future of piezoelectric sensor technology. You pick piezoelectric sensor solutions that fit your needs and keep up with new trends.

There are lots of new things happening with piezoelectric load sensor technology in 2025. Flexible sensors make it easy to use piezoelectric load sensor devices in many places. New materials help each piezoelectric load sensor work better. The market is growing because more people trust these solutions. You watch these trends to keep up. SOUSHINE brings new ideas and strong products. You will see even more progress soon.

FAQ

What is a piezoelectric load sensor?

A piezoelectric load sensor helps you measure force or pressure. When you push on it, the sensor makes an electric signal. This lets you see changes in weight or pressure right away.

How do SOUSHINE Force Sensing Resistors work?

You press the sensor and its resistance goes down. The sensor gives a steady signal as you push harder. You can see how much force you use with good accuracy.

Where can you use piezoelectric load sensors?

These sensors are found in cars, robots, and medical devices. You use them to make things safer and to track health. They also help control machines and electronics.

Are piezoelectric sensors safe for the environment?

You can pick lead-free and eco-friendly materials. These choices help you follow safety rules and protect nature.

Can you connect piezoelectric sensors to wireless systems?

Yes, you can link these sensors to wireless networks. You can get data from far away and watch machines or health without wires.

What makes SOUSHINE FSRs different from others?

SOUSHINE FSRs give you high accuracy and last a long time. They use little power and fit many designs. You can change them to match what you need.

How long do piezoelectric sensors last?

These sensors work well for a long time. They keep giving you good data even in tough places.

Do you need special tools to install these sensors?

No, you do not need special tools. You can add them to your system easily. The steps are simple and quick.