Call us: +86-137-2353-4866

You have to pick a pressure sensor transducer or a pressure transmitter for your job. Pressure sensor transducers are small and very accurate. Pressure transmitters work best for measuring levels and controlling processes in big industries like oil and gas. Picking the right device is important for monitoring, control, or safety in cars, machines, and healthcare. SOUSHINE has advanced pressure sensors and force sensing resistor solutions. These help you get reliable force sensing for what you need.

Table of Contents

Key Takeaways

- Pressure sensor transducers are small and very accurate. They measure air, gas, or liquid pressure. These devices are good for checking systems in many industries.

- Pressure transmitters make signals stronger for long distances. This makes them good for big jobs like oil and gas work.

- Pick the right device for your needs. Transducers are best for direct readings. Transmitters are better for control and remote checks.

- Think about where you will use the device. Things like heat, dust, and water can change how it works.

- Know what kind of signals you need. Transducers give simple signals. Transmitters give stronger and steadier signals for hard jobs.

- Look at the good and bad sides of each device. Transducers cost less and last long. But they may not be as accurate in some cases.

- SOUSHINE makes pressure devices you can change for your project. This helps you get the best device for your job.

- Always test the devices in your system first. Ask for samples to make sure they work well.

Pressure Sensor Transducer Basics

What Is a Pressure Sensor Transducer?

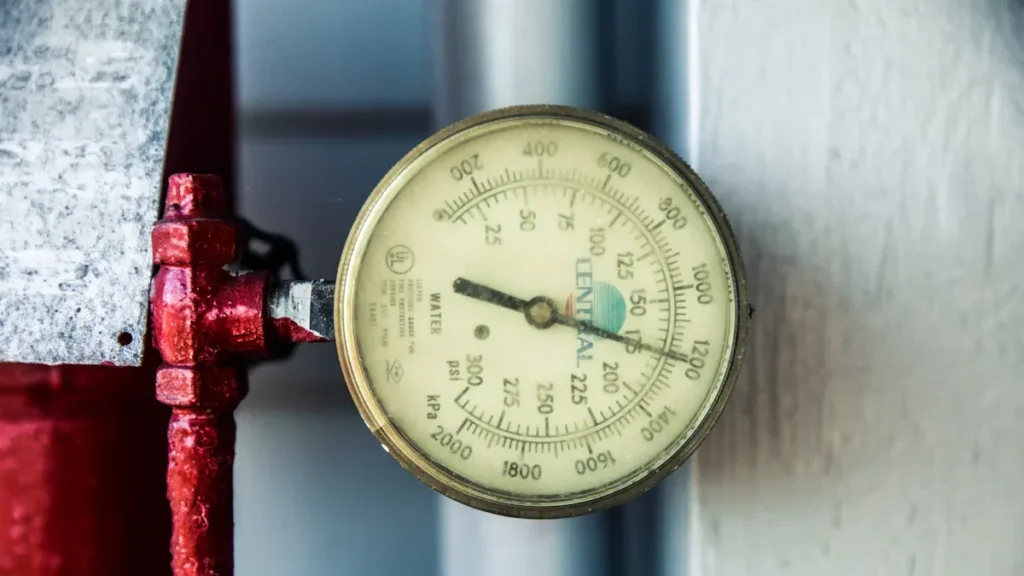

A pressure sensor transducer measures the pressure of air, gas, or liquid. You use it to watch and control different systems. Engineers call it a pressure transducer or pressure sensor. You see these devices in factories and machines. They help you know the exact pressure. Most pressure sensor transducers have a cover. The cover keeps out water and moisture. This helps you get correct readings every time. In oil and gas jobs, you use a pressure transducer to check pressure during work like fracking.

How Pressure Sensor Transducers Work

A pressure sensor transducer turns pressure into an electrical signal. When you press on it, a diaphragm inside moves. This movement makes an electrical output that matches the pressure. Some transducers use strain gauges. When the diaphragm bends, the resistance changes. The device measures this change to show the pressure. Other types use piezoelectric materials like quartz or tourmaline. These materials make electricity when you press them. Some pressure sensors use capacitive changes. The diaphragm moves and changes the space between two plates. This changes the electrical signal. Each way helps you measure pressure and use the data.

Tip: Pick the right pressure sensor transducer for your job. How it works can change how correct and steady your readings are.

Applications of Pressure Sensor Transducers

Pressure sensor transducers work in many areas. Here are some common uses:

- HVAC systems: You check and control air flow and pressure.

- Hydraulic pumps: You watch fluid pressure to keep machines safe.

- Test and measurement places: You collect data for research or quality checks.

You also find pressure sensors in cars, medical tools, and factory machines. These devices help keep things safe and working well. When you need to measure pressure with care, a pressure sensor transducer gives you the right data.

Pros and Cons of Pressure Sensor Transducers

When you pick a pressure sensor transducer, you want to know its good and bad sides. The table below shows the main strengths and weaknesses:

| Advantages | Limitations |

|---|---|

| Economical and designed on robust technologies | Moderate accuracy in case of drifts |

| Great stability and regulated output | Delayed response to shocks and vibrations |

| Highly sensitive, compact, and lightweight | Not reliable for high-temperature ranges |

| Simple to construct and highly durable | Highly sensitive to environmental conditions |

Advantages

Pressure sensor transducers give you many benefits:

- You save money because they cost less.

- They are stable and give steady readings.

- Their small size makes them easy to put in tight spots.

- They can notice tiny changes in pressure.

- They are built simply, so they last a long time.

Note: You can trust a pressure sensor transducer for lots of jobs. It works well in factories and hospitals because it is tough and accurate.

Limitations

There are some things to watch out for:

- Accuracy can drop if the device drifts.

- If there are sudden shocks or strong shakes, it may react slowly.

- High heat can make it less reliable, so check the temperature range.

- Things like dust or wet air can change how it works.

SOUSHINE Pressure Sensor Transducer Solutions

SOUSHINE offers advanced pressure sensor transducers that are special in the market. You get high accuracy and quick response, so you see data right away. SOUSHINE makes sensors that work with many types of liquids and gases. You can use them in lots of industries. The output signals are flexible, so you can match the sensor to your system easily.

You also get:

- Low maintenance, so you do not need to fix them often.

- Easy installation, even in small or hard places.

- Reliable use in cars, hospitals, and factories.

- Designs that fit new projects or upgrades.

SOUSHINE pressure sensor transducers help you measure pressure with trust. You get a device that works for your needs, whether you are in a car plant, a hospital, or a lab.

Pressure Transducer vs Pressure Transmitter

What Is a Pressure Transducer?

A pressure transducer checks the pressure of a liquid or gas. It changes this pressure into an electrical signal. The device sits inside machines or systems. It gives you a direct reading. The signal is a small voltage that matches the pressure. You see pressure transducers in labs or small control systems. They give quick and accurate data. The design is simple, so it fits in tight spaces. You can connect it to a display or computer to see the results.

What Is a Pressure Transmitter?

A pressure transmitter takes a signal from a sensor. It changes the signal into a stronger output. You use a transmitter to send pressure data far away. It works well with control systems. The transmitter can give signals like voltage, current, or digital data. You find transmitters in big factories and oil plants. They are used where you need to watch pressure all the time. The device has extra electronics to make the signal steady. This makes it easy to read. You can set up a transmitter for smart systems. This helps you get better control and safety.

How They Differ in Operation

You might wonder how these two devices work differently. The main difference is how each handles the signal. It also matters how you use them in your system. Here is a table to help you see the differences:

| Feature | Pressure Transducer | Pressure Transmitter |

|---|---|---|

| Output Signal | Proportional to supply, typically mV | Can be voltage, current, frequency, or digitalized |

| Signal Processing | No standardization or compensation | Linearizes, amplifies, modifies, and digitalizes |

| Calibration | Measures at live zero conditions | Can be calibrated for zero span adjustment |

| Integration | Requires SCADA for remote monitoring | Can be calibrated using HART protocol, termed smart transmitters |

A pressure transducer gives a simple signal. You need extra equipment to read or send the data far. A pressure transmitter gives a strong, steady signal. It works with many control systems. You can use a transmitter for remote monitoring. It also helps you adjust and calibrate the system. If you need basic measurement, pick a transducer. If you want full control and easy setup, choose a transmitter.

Tip: Always check what your system needs before you pick between a transducer and transmitter. The right choice helps you get better results and saves you time.

Applications for Pressure Transducers and Transmitters

You find pressure transducers and transmitters in many fields. These devices help you watch and control important systems. Here are some common ways people use them:

- Hydraulic Systems: You use these to control force in machines. Hydraulic machines work in tough places, so you need shock-resistant devices.

- Safety Control Systems: These devices are in air compressors. They help keep things safe and stop accidents.

- Injection Molding: Pressure sensors go in injection molding machines. They help you check and change pressure during making parts.

- Mining Pressure Monitoring: You use these to check pressure in mines. This keeps workers and machines safe.

You also see these devices in water plants, oil refineries, and chemical factories. They help you keep everything running safely and smoothly.

Pros and Cons of Pressure Transmitters

When you pick a pressure transmitter, you want to know its good and bad sides. The table below shows the main advantages and limits:

| Advantages | Limitations |

|---|---|

| Accurate Measurement | Calibration and Maintenance |

| Real-time Monitoring | Limited Pressure Ranges |

| Automation | Compatibility |

| Remote Monitoring | Environmental Conditions |

| Data Integration | Initial Cost |

| Safety Enhancement | Mechanical Wear |

| Energy Efficiency | Complexity |

| Quality Control | Electromagnetic Interference |

| Process Optimization | Specific Applications |

| Diagnostics |

Advantages

Pressure transmitters give you many good things. They measure pressure well and show real-time data. You can connect them to automation systems for better control. Remote monitoring lets you check pressure from far away. Data integration helps you collect and use information for reports. These devices also make things safer and save energy. You can use them for quality control and to make processes better. Diagnostics help you find problems fast.

Tip: If you want better safety and control, a pressure transmitter is a smart pick.

Limitations

You should know the limits too. You must calibrate and take care of these devices. Some only work in certain pressure ranges. You might have trouble with old systems. Dust or wet air can change how they work. The first price can be high. Parts may wear out after a while. Some setups are hard and need experts. Electromagnetic interference can cause issues. Some transmitters only work for special jobs.

SOUSHINE Pressure Transmitter Products

SOUSHINE has high-quality pressure transmitter products for your needs. You can pick standard sizes or ask for custom ones. These transmitters use strong aluminum and come in original or custom colors. You can get free samples, but you pay for shipping. SOUSHINE makes these products in Dongguan City, Guangdong Province, China.

| Specification | Details |

|---|---|

| Product Name | High Quality Force Sensing Resistor Film Force Pressure Sensor |

| Product Size | Standard Size/Customized |

| Product Material | Aluminum |

| Product Color | Original Color/Customized |

| Sample | Free Samples, Shipping Fee Required |

| Place Of Production | Dongguan City, Guangdong Province, China |

You get steady performance and many choices with SOUSHINE transmitters. These products work in many fields and help you watch pressure with care.

Pressure Switches Explained

What Is a Pressure Switch?

A pressure switch helps control machines using fluid pressure. It has a sensor and an electrical switch. When pressure hits a certain level, the switch turns on or off. You see pressure switches in places where safety is important. The main parts are a process fitting, a pressure sensor, a microswitch, and a strong case. You set the switch to work at a chosen pressure, called the setpoint. When pressure changes, the switch acts fast.

- A pressure switch controls a circuit when fluid pressure reaches a set level.

- It quickly reacts to pressure changes to run systems.

- The main parts are a process fitting, a pressure sensor, a microswitch, and a case.

How Pressure Switches Work

A pressure switch works by using the force from fluid or air. It follows Pascal’s Law, which means pressure spreads out evenly in a closed space. When pressure pushes on the sensor, the switch reacts. There are mechanical and electronic types. Mechanical switches use parts like bourdon tubes, pistons, or diaphragms. If pressure goes past the setpoint, the piston moves and pushes a spring. This flips the switch. You can change the setpoint with a screw. Electronic switches use sensors to find pressure and send a signal.

- Pressure switches can be mechanical or electronic and work with fluid, air, or gas pressure.

- They use parts like bourdon tubes, pistons, or diaphragms that move when pressure changes.

- In a pressure switch, a piston moves when fluid pressure is high enough, pushing against a spring.

Applications of Pressure Switches

Pressure switches are used in many industries. They help keep systems safe and working well. You find them in factories, buildings, oil fields, water plants, and farms. The table below shows how they are used and what they do:

| Use Case | Description |

|---|---|

| Industrial Automation and Safety | Controls machines like hydraulic presses and robots to keep things safe and products good. |

| HVAC and Building Management | Keeps air and water pressure steady, saving energy and making systems last longer. |

| Oil & Gas Extraction and Processing | Watches pressure to stop blowouts and leaks, keeping workers safe. |

| Water Treatment and Supply | Runs pumps and valves to keep water flowing and follow rules. |

| Agricultural Irrigation | Turns on irrigation when soil is dry, saving water and helping crops grow. |

Pressure switches protect equipment and people. In HVAC, they keep air and water pressure right. In oil and gas, they stop leaks. Water plants use them to control pumps and valves. Farmers use them to water crops only when needed. The right pressure switch gives you better safety, control, and efficiency.

Pros and Cons of Pressure Switches

When you pick a pressure switch, you want to know the good and bad things. Pressure switches have many features that help in different jobs. You can see how they compare in the table below.

| Advantages | Disadvantages |

|---|---|

| Enhanced functionality and integration | Higher initial cost and complexity |

| Improved precision and control | Power dependency and potential for electronic failure |

| Enhanced integration with smart systems | Maintenance and service considerations |

| Durability and environmental resistance | |

| User-friendly features and adjustability |

Advantages

A pressure switch lets you control machines better. You can set it to turn on or off at the pressure you want. This keeps your system safe and working right. Many pressure switches work with smart systems. You can connect them to automation for better results. You can change the settings easily for different jobs. The strong design lets you use it in tough places. It works in factories or outside. Most switches can handle dust and water. You get better precision, so your system reacts fast when pressure changes.

Tip: Use a pressure switch to make your system safer and smarter. Set the setpoint to fit your needs for the best results.

Limitations

You should know some limits before you pick a pressure switch. Some switches cost more at first because of extra features. You may need more time to set them up if your system is hard. Many pressure switches need power, so check for electronic problems. If the switch fails, your system might stop. You also need to check and fix the switch often. This keeps it working well and stops problems. Sometimes, you need special help if the switch has advanced parts.

Note: Always check the power and plan for maintenance. This helps your pressure switch last longer.

Force Sensing Resistors (FSRs) by SOUSHINE

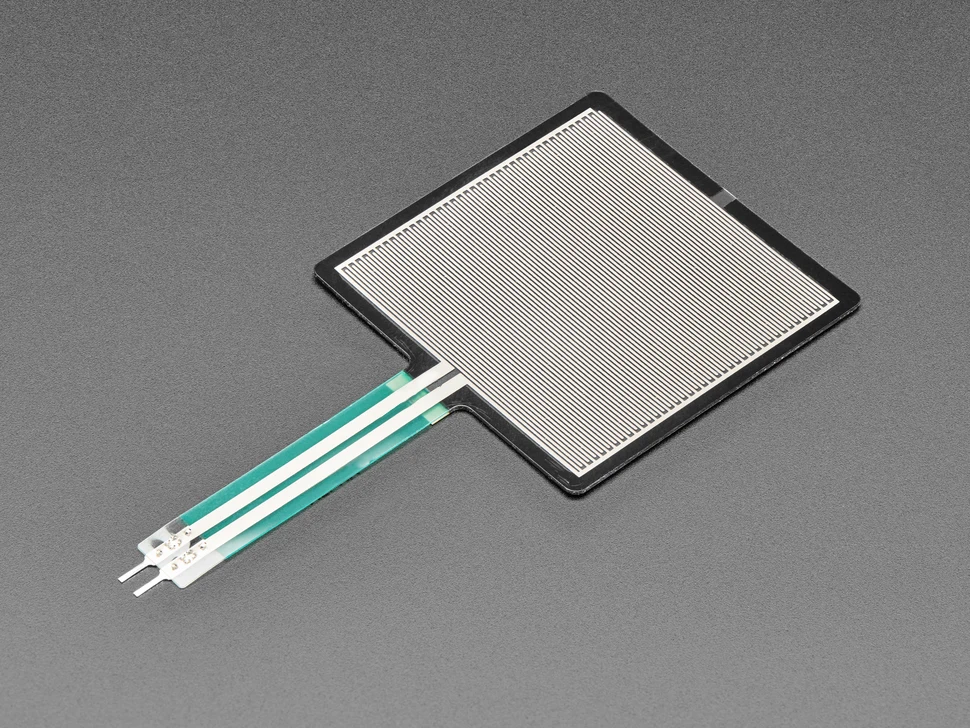

What Are Force Sensing Resistors?

A force sensing resistor (FSR) is a special material. It changes resistance when you press on it. If you push or squeeze it, the resistance goes down. This makes FSRs great for finding touch or pressure in devices. SOUSHINE makes FSRs that measure force well. You can use them in robots, medical tools, or smart gadgets.

Tip: FSRs show how much force you use, not just if you touch.

How FSRs Measure Pressure and Force

FSRs work in a simple way. Inside, there are layers of conductive ink. A thin spacer keeps them apart. If you do not press, resistance is very high. When you press, the layers touch each other. This lets electricity flow better and lowers resistance.

- FSRs have layers of conductive ink with a spacer.

- No pressing means high resistance.

- Pressing connects layers and drops resistance.

The main part of an FSR is a piezoresistive element. It sits between two flexible pieces. With no force, resistance is very high. When you press, particles move closer and resistance drops. You can measure this with a voltage-divider circuit. More force means lower resistance. This change is almost straight, so you can tell how much force you use.

Note: FSRs let you measure different force levels. You get more control and better feedback for your projects.

FSR Applications Across Industries

FSRs are used in many places because they are easy to use. Here are some ways you might see FSRs:

- Robotics and Automation: FSRs help robots feel touch. They give feedback for grippers and help with collision detection.

- Medical Devices: FSRs are in prosthetic sensors and bed monitors. They help with force mapping for rehab.

- Wearable Technology: Smart shoes and gloves use FSRs. Sports trackers use them to measure movement and force.

- Industrial Control: FSRs watch equipment pressure and give feedback on assembly lines. They keep operator panels safe.

- Consumer Electronics: Gaming controllers and musical instruments use FSRs. Touch buttons and smart home devices use them too.

FSRs help make products smarter, safer, and more responsive in many industries.

Advantages of SOUSHINE FSRs

When you pick SOUSHINE FSRs, you get more than a simple sensor. These force sensing resistors work well in many ways. The table below shows the main advantages:

| Advantage | Description |

|---|---|

| Enhanced Sensitivity | SOUSHINE FSRs react fast to touch or weight changes. You get quick and correct feedback. |

| Durability | The sensors use tough materials. They keep working in hard places. |

| Environmental Adaptability | SOUSHINE FSRs work in very hot or cold temperatures. You can use them in hospitals, factories, or outside. |

SOUSHINE FSRs notice even tiny changes in force. This helps you get instant feedback for your projects. The sensors last long because they are made with strong materials. You can trust them in places with dust, water, or heat. Other sensors might stop working, but SOUSHINE FSRs keep going when you need them.

Tip: If you want a sensor that works almost anywhere and gives you fast results, SOUSHINE FSRs are a good pick.

Customization and Integration Support

SOUSHINE knows every project is different. You might want a special shape or a certain force range. You may need a unique way to connect your sensor. SOUSHINE gives you many choices to help you get the right FSR:

- Custom FSR Prototype: You can ask for a design that fits your needs.

- Mass Production Solution: SOUSHINE can make lots of FSRs and keep them high quality.

- OEM Private Labeling: You can put your own brand and packaging on the sensors.

- Customization Options: Pick the shape, force range, output type, and connection that works for you.

- End-to-End OEM/ODM Services: SOUSHINE helps you from design to making the product. You can get help at every step, even with NDA support for your ideas.

- Easy Communication: You can send your needs by email, talk on the phone, or visit for a meeting.

You do not have to use a sensor that does not fit your project. SOUSHINE helps you make the best FSR for your job. You get help from your first idea to the finished product.

Note: If you have a special project or need help with connecting your sensor, SOUSHINE’s team is ready to help you.

Key Differences and Comparison

Output Signal Types

When you pick a pressure device, you should know the signal it sends. Each device gives a different output. This changes how you connect and read the data.

| Device Type | Typical Output Signal Types |

|---|---|

| Pressure Transducer | Millivolt (mV), Voltage (0-5V, 0-10V), sometimes digital |

| Pressure Transmitter | Current (4-20mA), Voltage, Frequency, Digital (RS485, CAN) |

| Pressure Switch | On/Off (discrete), sometimes digital |

| FSR (Force Sensing Resistor) | Resistance change (analog), can be converted to voltage or digital with extra electronics |

- Millivolt outputs are very precise but can get noisy.

- Voltage outputs work well in most places and block noise.

- Current outputs (like 4-20mA) are best for long wires.

- Frequency outputs change with pressure and block interference.

- Digital outputs (like RS485 or CAN) are very accurate and work with smart systems.

- Pressure switches give a simple on/off signal.

- FSRs change resistance when pressed. You can use a circuit to turn this into voltage or digital.

Tip: Always check your system’s signal needs before picking a device. This helps you avoid extra wires or converters.

Accuracy and Reliability

You want your pressure device to give correct and steady readings. Each type has its own strengths for accuracy and reliability.

- Pressure Transducers are very accurate for direct readings. They stay stable if you use them in the right place.

- Pressure Transmitters have extra electronics to make signals strong and steady. You can trust them for a long time and in noisy places.

- Pressure Switches are good for safety and control. They react fast when pressure hits a set point. You do not get lots of details, but you get quick and steady switching.

- FSRs give good feedback for touch and force. They work best for finding changes in force, not for exact pressure numbers. You can count on them for quick response and long life.

| Device Type | Accuracy Level | Reliability Factors |

|---|---|---|

| Pressure Transducer | High | Needs stable environment, sensitive to drift |

| Pressure Transmitter | High | Strong signal, resists noise, long-term use |

| Pressure Switch | Moderate | Fast response, simple, less detail |

| FSR | Moderate | Quick feedback, durable, best for touch |

If you need exact numbers, pick a transducer or transmitter. If you want fast action or touch feedback, a switch or FSR is better.

Complexity and Installation

Putting in a pressure device can be easy or hard. It depends on what you pick. You should think about where you use it and what your system needs.

- Pressure Transducers are small and fit in tight spots. You need to connect them to a display or data system. You must check for the right voltage and signal.

- Pressure Transmitters need more wires because they send signals far. You may need to set up calibration and check power. They often need protection from dust, water, or heat.

- Pressure Switches are easy to install. You set the pressure point and connect the switch to your control system. You must make sure the switch matches your voltage and current.

- FSRs are thin and flexible. You can stick them on surfaces or put them in small devices. You need a simple circuit to read the resistance change.

Key things to check before installing:

- Pressure range: Make sure the device can handle your system’s pressure.

- Temperature: Check if the device works in your environment.

- Media compatibility: Make sure the device materials work with your fluids or gases.

- Electrical needs: Match the device’s output to your system.

- Environmental protection: Look for the right IP rating for dust or water.

- Certifications: Some jobs need special safety marks like UL or ATEX.

| Device Type | Installation Complexity | Main Considerations |

|---|---|---|

| Pressure Transducer | Low to Moderate | Space, wiring, signal compatibility |

| Pressure Transmitter | Moderate to High | Wiring, calibration, protection, distance |

| Pressure Switch | Low | Setpoint adjustment, voltage, current |

| FSR | Low | Placement, simple circuit, flexibility |

Note: Always check your system’s needs before you install. Picking the right device saves time and keeps your system safe.

Cost and Value

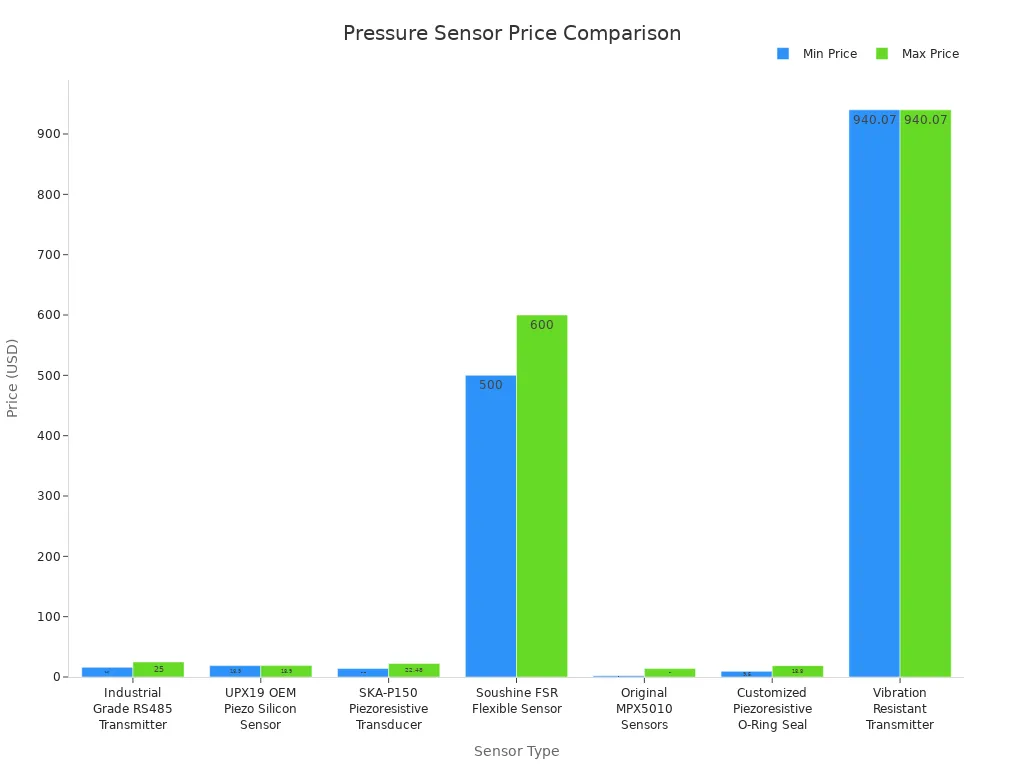

When you pick a pressure device, you want to know the price. Each sensor or switch costs a different amount. Some are cheap and only do simple jobs. Others cost more but last longer or have more features.

Here is a table that shows the price range for popular pressure devices:

| Sensor Type | Price Range | Minimum Order | Manufacturer |

|---|---|---|---|

| Industrial Grade RS485 Pressure Transmitter | $16-25 | 5 pieces | Jurong Jiazhun Sensor Technology Co., Ltd. |

| UPX19 OEM Low Price Piezo Silicon Pressure Sensor | $18.90 | 10 pieces | Xi’an UTOP Measurement Instrument Co., Ltd. |

| SKA-P150 Piezoresistive Silicon Core Transducer | $14.15-22.48 | 10 pieces | Shanghai Kara Instruments Co., Ltd. |

| Soushine FSR Flexible Sensor | $500-600 | 5 pieces | Dongguan Soushine Industry Co., Ltd. |

| Original MPX5010 and MPX5010DP pressure sensors | $2-14 | 1 piece | Lixinc Electronics Co., Limited |

| Customized Piezoresistive Silicon O-Ring Seal | $9.50-18.80 | 500 pieces | Shanghai Kara Instruments Co., Ltd. |

| Vibration Resistant Pressure Transmitter | $940.07 | 1 piece | VIRTUOSO PROJECTS & ENGINEERS PRIVATE LIMITED |

You can see that basic pressure sensors are cheaper. Devices with more features or better accuracy cost more. The price changes because of the technology and what the device can do.

Think about what you get for the price, not just the cost. A cheap sensor is fine for easy jobs. If you need more accuracy or special features, you may pay more. SOUSHINE FSRs give you smart sensing and last a long time. Pressure transmitters help you watch things from far away. Pressure switches are good for fast safety control.

Tip: Pick a device that fits your needs and your budget. A higher price can mean better features or longer life.

Application Suitability

You need the right pressure device for your job. Each type works best in certain places.

- Pressure transducers are good for labs, test benches, and small machines. They give you direct and accurate readings.

- Pressure transmitters are best for big factories and oil plants. You can use them for remote monitoring and automation.

- Pressure switches are used for safety and control. You see them in HVAC, water plants, and machines that need quick on/off.

- FSRs are great for touch sensing, robots, and healthcare. You find them in smart shoes, medical tools, and robot hands.

You see differential pressure sensors in HVAC systems. They help you check air flow and find problems early. Gauge pressure sensors are used in healthcare. You find them in breathing machines and patient monitors. Relative pressure sensors help HVAC systems get ready for heating or cooling.

Pressure sensors are important in factories. You use them to watch pipes, find leaks, and keep things safe. You see them in water plants, chemical factories, and airplanes.

If you know your job, you can pick the best device. This helps you save money and get better results.

Comparison Table: Transducer, Transmitter, Switch, FSR

You can look at all four types together. This table helps you see which one is best for you.

| Feature | Pressure Transducer | Pressure Transmitter | Pressure Switch | FSR (Force Sensing Resistor) |

|---|---|---|---|---|

| Output Signal | mV, Voltage | Current, Voltage, Digital | On/Off | Resistance change |

| Accuracy | High | High | Moderate | Moderate |

| Installation | Easy, compact | Moderate, needs wiring | Simple | Very easy, flexible |

| Cost | Low to moderate | Moderate to high | Low to moderate | High |

| Value | Good for direct readings | Best for automation and remote monitoring | Best for safety and control | Best for touch and force sensing |

| Application | Labs, test benches | Factories, oil plants | HVAC, water plants | Robotics, healthcare, consumer electronics |

Use this table to match your job and budget to the right device. You get better results when you choose the best fit.

Choosing the Right Pressure Device

Step-by-Step Selection Guide

You want to pick the best pressure device for your project. Follow these steps to make a smart choice:

- Check the Environment

Look at where you will install the device. Ask if the area is indoors or outdoors. Notice if there is salt air, dust, or water. Some places need special protection. - Know Your System Pressure

Write down the normal and highest pressure your system will see. Pick a device that can handle both. This keeps your system safe. - Set Point and Deadband

Decide the pressure level where you want the device to act. This is your set point. Also, think about the deadband, which is the range where the device does not react. A good deadband stops the device from switching on and off too often. - Choose the Right Switch Type

Some jobs need a single-pole double-throw (SPDT) switch. Others need a double-pole double-throw (DPDT) switch. Pick the one that matches your control system. - Check Process Media and Materials

Make sure the device’s parts can handle the fluid or gas in your system. Some chemicals need special materials. - Think About Output Signals

Decide if you need a simple on/off signal, a voltage, a current, or a digital output. Match the device to your control system.

Tip: Always match the device’s features to your job. This helps you avoid problems later.

Application Checklist

You can use this checklist to see if a pressure device fits your needs. The table below shows what to check for different jobs:

| Specification Category | Key Parameters | Typical Ranges | Industry Standards |

|---|---|---|---|

| Pressure Requirements | Working, burst, vacuum | 150-6000 PSI working pressure | SAE, API, ISO |

| Temperature Limits | Operating, peak temperatures | -40°F to +400°F continuous | ASTM, UL |

| Chemical Compatibility | Fluid types, concentration | pH 2-12, various solvents | FDA, NSF, USDA |

| Physical Properties | Bend radius, length, diameter | 1/4″ to 12″ ID, custom lengths | ANSI, JIC fitting |

Industrial Automation

You need strong and reliable devices in factories. Pick sensors that handle high pressure and fast changes. Make sure the device fits your control system and meets safety rules.

HVAC Systems

You want to keep air and water pressure steady. Choose devices that work in hot and cold places. Make sure they fit in tight spaces and connect to your building controls.

Safety and Alarm Systems

You must react fast to danger. Use pressure switches or transmitters with quick response. Pick devices with clear set points and strong cases for harsh places.

Automotive and Robotics

You need small, light, and tough sensors. FSRs work well for touch and force feedback. Pick devices that fit in small spaces and handle shocks.

Healthcare Devices

You want safe and clean sensors. Pick devices with medical-grade materials. Make sure they give steady readings and work with your monitors.

Common Selection Mistakes

You can avoid many problems by watching out for these mistakes:

- Many people ignore the environment. This can cause the device to fail early or create safety risks.

- Some choose the wrong pressure range. This can give you bad readings or even break your system.

- Others forget to check the output signal. This can make it hard to connect the device to your controls.

Note: Always check the details before you buy. This saves you time and money.

SOUSHINE Product Selection Tips

Picking the right pressure device can seem hard. SOUSHINE makes it easier for you. You get help from experts, many choices, and products you can trust. Here are some tips to help you:

1. Define Your Application Needs

Start by writing down what your project needs. List the pressure range, where you will use it, and the signal type you want. If you need a sensor for touch or force, look at SOUSHINE FSRs. For watching pressure all the time, check SOUSHINE pressure transmitters.

2. Use SOUSHINE’s Customization Services

SOUSHINE lets you change your device in many ways. You can pick the shape, size, and output signal. If you need a sensor for a special machine, ask for a custom prototype. SOUSHINE’s team helps you from your first idea to the finished product.

| Customization Option | What You Get |

|---|---|

| Shape & Size | Fit sensors into small spaces |

| Output Signal | Match your control system |

| Force Range | Pick the right sensitivity |

| Connection Type | Easy to connect to your setup |

3. Ask for Expert Support

You do not have to figure out everything by yourself. SOUSHINE’s engineers answer your questions and help you pick the best device. You can talk to them by email, phone, or online chat. If your project is hard, you can set up a meeting for more help.

Tip: Always tell SOUSHINE’s team about your project. The more they know, the better they can help you.

4. Request Samples for Testing

You can ask SOUSHINE for samples before you buy a lot. Test the sensor in your system. See if it fits and works the way you want. This step helps you avoid mistakes and saves money.

5. Review Quality and Certifications

SOUSHINE checks quality very carefully. You get products that meet industry rules. If you need special certifications, ask for proof before you order.

6. Plan for Future Growth

Think about what you might need later. If your project could get bigger, pick devices that can grow with you. SOUSHINE has solutions for small and big orders. You can start with a few sensors and get more when you need them.

7. Use SOUSHINE’s Integration Support

SOUSHINE helps you connect sensors to your system. You get advice on wiring, changing signals, and setting up software. If you need help with installation, ask for step-by-step guides.

Note: SOUSHINE keeps helping you after you buy. You get support during setup and after your project starts.

Quick Checklist for SOUSHINE Product Selection

- Do you know your pressure or force range?

- Did you pick the right output signal?

- Did you check the environment and media compatibility?

- Do you need a custom shape or size?

- Did you ask for samples?

- Are you planning for future growth?

- Did you contact SOUSHINE for expert help?

You can trust SOUSHINE to help you pick the best pressure device. You get products you can count on, expert help, and many choices for every project.

You have learned how pressure sensor transducers, transmitters, switches, and FSRs are different. Each one works best for a certain job. Use transducers when you need direct readings. Pick transmitters if you want to check pressure from far away. Switches help keep things safe by turning systems on or off. FSRs are good for sensing touch or force. SOUSHINE can help you with expert advice and many products. If you want the right device for your project, ask SOUSHINE for custom help and tips.

FAQ

What is the main difference between a pressure transducer and a pressure transmitter?

A pressure transducer sends an electrical signal right away. A pressure transmitter makes the signal stronger for sending far. Use a transducer for close-up checks. Use a transmitter for watching from far away or for control.

When should you choose a pressure switch instead of a sensor?

Pick a pressure switch if you want easy on/off control. It works well for alarms and safety systems. Pressure switches act fast when pressure hits a set level. Sensors give you steady data all the time.

Can you use SOUSHINE FSRs in outdoor environments?

You can use SOUSHINE FSRs outside. They stand up to dust, water, and heat or cold. You get good results even in hard places. Always look at the product details before you use them.

How do you connect a pressure sensor to your system?

Connect a pressure sensor with wires or special plugs. Make sure the signal matches your system. Follow the guide for setup and wiring. Test the sensor before you use it fully.

What industries use force sensing resistors most?

FSRs are used in robots, healthcare, cars, and smart gadgets. They help with touch, patient checks, and smart controls. You also see them in factories and airplanes.

Can you customize SOUSHINE pressure devices for your project?

You can ask for special shapes, sizes, or signals. SOUSHINE helps with design and custom orders. You get sensors made just for your project.