Call us: +86-137-2353-4866

Have you ever thought about how machines know when you touch them or how hard you press? Tactile sensors change how you use technology every day. These devices help robots, medical tools, and your phone sense force and pressure. The tactile market is getting bigger, with values in the billions of dollars around the world. Experts think it will keep growing fast in the next ten years.

Tactile sensors are very important in many uses. For example, in healthcare robots, tactile sensing helps them touch patients safely and gently. In rehab devices, tactile sensors check force to make sure movements are safe.

Tactile sensing, force sensing, and the force sensing resistor all help machines feel and react in new ways.

Table of Contents

Key Takeaways

Tactile sensors let machines sense touch and pressure. This makes technology more interactive for people. The market for tactile sensors is growing fast. They are used in healthcare, robotics, and electronics. Early tactile sensors were simple mechanical tools. Now, they are more sensitive and flexible. New materials like graphene and silver nanowires help a lot. They make tactile sensors more accurate and strong. Smaller tactile sensors can fit in tiny devices. These include smartwatches and medical tools. Tactile sensors make smartphones and games better. They give real-time feedback to users. In healthcare, tactile sensors help prosthetics users feel touch. This helps them do daily tasks better. In the future, tactile sensors will use self-healing materials. They will also use AI for smarter actions.

Tactile Sensor Origins

Early Mechanical Designs

Tactile sensor technology started in the mid-1900s. Engineers and scientists made simple mechanical devices for research. These first sensors let machines feel pressure and force. The first tactile sensor was made in 1957 by Chodera. He built a pedobarograph to measure foot pressure. In 1960, MIT made a small pedobarograph for robot hands. Kappl used photoelastic polyurethane rubber in 1963 for a visual-tactile sensor. In 1966, Stricler worked on making clear optical stress patterns for visual-tactile sensors. Schneiter and Sheridan, in 1984, made an optical touch sensor for robots with optical fiber.

Here is a table that lists some early tactile sensor research and development:

| Year | Development Description |

|---|---|

| 1957 | Chodera made the first tactile sensor, a pedobarograph. |

| 1960 | MIT made a tactile sensor for robot hands. |

| 1963 | Kappl built a visual-tactile sensor with special rubber. |

| 1966 | Stricler studied optical stress patterns for sensors. |

| 1984 | Schneiter and Sheridan made an optical touch sensor for robots. |

1970s Innovations

In the 1970s, new ideas changed tactile sensor research. Engineers used mechanical ideas and new materials. They wanted sensors to measure force, pressure, and touch. Capacitive sensors measured changes in capacitance. These used elastomeric separators. Piezoresistive sensors checked resistance changes when stressed. They used conductive rubber and piezoresistive ink. Piezoelectric sensors made electric charge when pressed or bent. Plastics, crystals, ceramics, and PVDF were common materials.

| Sensor Type | Mechanical Principle | Materials Used |

|---|---|---|

| Capacitive | Measures changes in capacitance | Elastomeric separator |

| Piezoresistive | Measures resistance changes under stress | Conductive rubber, piezoresistive ink |

| Piezoelectric | Makes electric charge from deformation | Plastics, crystals, ceramics, PVDF |

First Theoretical Models

In the 1970s, researchers started making models for tactile sensor design. These models showed how sensors react to force and pressure. The work helped improve robotic hands and automation.

Key Milestones in the 1980s

The 1980s were important for tactile sensor progress. Research and technology moved forward quickly. Engineers made new sensors and better ways to process data. These changes helped factories and robots.

Piezoresistive Sensors (1981)

Hillis made piezoresistive tactile sensors in 1981. These sensors were used in small arrays for robots and prosthetics. They measured forces from 0.01 to 1 N. The design used flexible circuit boards and conductive silicon rubber. These sensors were more sensitive at lower forces. Robots and medical tools used them more because they worked well.

| Feature | Description |

|---|---|

| Year Introduced | 1981 |

| Developer | Hillis |

| Application | Small array for robots and prosthetics |

| Measurement Range | 0.01 to 1 N |

| Sensitivity | Better at lower forces |

| Design | Flexible circuit board, conductive silicon rubber |

| Impact on Adoption | Better sensitivity led to more use in robots and medicine |

Design Criteria by Harmon (1982)

Harmon set rules for tactile sensor design in 1982. Sensors had to be reliable, sensitive, and easy to use in machines. This research helped engineers make better sensors for automation.

MIT Tactile Sensor (1983)

MIT made a new tactile sensor in 1983. It made robotic touch better. The sensor used new materials and design. MIT’s work helped tactile sensor technology grow. Today’s robots and machines use these ideas.

Advances in Tactile Sensor Technology

Early tactile sensors helped start new ideas. Now, new materials and smaller sizes have changed tactile sensors. These changes make sensors more accurate and flexible. They are now useful in many areas.

Material Breakthroughs

Piezoelectric and Piezoresistive

Piezoelectric and piezoresistive materials have made tactile sensors better. When you press a piezoresistive sensor, its resistance changes. This makes the sensor accurate and reliable. Some flexible piezoresistive sensors use silver nanowires or graphene. These materials keep working well even when bent or stretched. You can use these sensors in wearables that move with your body.

Piezoelectric sensors work in a different way. They make a voltage when you press them. This helps measure fast pressure changes very well. These sensors are good for tracking movement or quick force changes. Both types have made tactile sensors more accurate.

Capacitive and Resistive

Capacitive and resistive sensors each have special uses. Capacitive sensors can sense small pressure and texture changes. They react fast and fit into soft materials. You can use them in soft robots and smart touch sensors. They are very accurate, but the environment can affect them.

Resistive sensors are tough and not expensive. They work well in rough places and block electromagnetic noise. They last a long time, but are less accurate than capacitive sensors. Using them a lot can make them less reliable. Both types are found in many modern devices.

- Key material innovations in tactile sensor technology include:

- Flexible substrates for wearable sensors

- Magneto-elastomers for magnetic tactile sensors

- Graphene and PVDF composites for e-skin

- Silver nanowires for flexible piezoresistive sensors

These materials help sensors stay accurate, flexible, and strong.

Miniaturization and MEMS

Making sensors smaller has changed tactile sensors a lot. MEMS technology lets you make tiny sensors that are still accurate. These sensors fit in small devices like wearables and portable gadgets.

| Advantage | Description |

|---|---|

| Miniature size | You can use sensors as small as 1 to 100 micrometers in compact devices. |

| Low power consumption | Sensors use very little power, making them ideal for battery-powered wearables. |

| High accuracy | MEMS sensors give you precise measurements, even at very small scales. |

Smaller sensors can go in places they could not before. Now, you can put tactile sensors in smartwatches, fitness bands, and medical patches.

Flexible and Wearable Sensors

Flexible and wearable tactile sensors are important today. You can put them in clothes, medical tools, and fake skin. They bend and stretch with you, but still work well and feel comfortable.

| Sensor Type | Description |

|---|---|

| Optical tactile device | Uses carbon nanotubes in flexible film for touch sensing |

| Wearable photonic sensor | Uses shape-memory cellulose for wearable applications |

| Pressure mapping device | Maps pressure for handwriting analysis |

| Self-power light-emitting fabric | Lights up using energy from your motion |

| E-skin | Mimics human skin using graphene and PVDF |

| Intelligent keyboard | Detects touch patterns for user identification |

You can find these sensors in smart clothes, health trackers, and interactive gadgets. They help you watch your health, stay safe, and use technology in new ways.

New materials and smaller sizes have helped tactile sensors get better. Now, you can use advanced touch sensors that are accurate and flexible. These changes make tactile sensors important in wearables and many other areas.

Influential Innovators and Devices

Pioneers in Tactile Sensing

Kinoshita et al.

Kinoshita and his team made big changes in tactile sensors. They studied how these sensors work in robot hands. Their research showed how robots can grab and hold things. Kinoshita’s work helped people use tactile feedback for better control. Many new tactile sensors use ideas from their research.

Rob Podoloff and MIT Team

Rob Podoloff and the MIT team changed tactile sensors in robots. They made sensor arrays that let robots feel pressure and force. Their work helped robots pick up fragile things without breaking them. The MIT team also made sensors that fit in small spaces. Many products today use their ideas.

Landmark Products

SOUSHINE Force Sensing Resistors (FSRs)

SOUSHINE Force Sensing Resistors (FSRs) are used in many fields. These sensors measure force and pressure very well. People use them in cars, hospitals, robots, and electronics. SOUSHINE FSRs change resistance when you press on them. This lets you measure force all the time, which helps control machines.

The sensor has a flexible base, a spacer, and a layer that conducts electricity. When you press it, electricity flows, so you can tell how much force is used. You can pick different shapes and sizes for your project. SOUSHINE FSRs last a long time and use little energy. You can put them in devices that run on batteries and need to save power.

SOUSHINE FSRs help make cars safer, watch patients in hospitals, and give robots a sense of touch.

Here is a table that shows what makes SOUSHINE FSRs special and how they help different industries:

| Defining Feature | Industry Impact |

|---|---|

| Customizable Shapes and Sizes | Lets you design for many uses. |

| Durability and Reliability | Makes products last longer and work better in tough places. |

| Low Power Consumption | Good for battery devices and saves energy. |

| Ease of Integration | Easy to add to other systems, so more people can use them. |

| Automotive Industry | Makes cars safer and improves how people use them. |

| Robotics | Helps robots hold things and move better in tricky places. |

| Medical Devices | Important for watching patients and helping them get better. |

| Consumer Electronics | Makes devices easier to use and more fun. |

| Industrial Automation | Helps factories work better and make good products. |

| Sporting Goods | Helps athletes track how they do and train better. |

People trust SOUSHINE for tactile sensor needs. Their FSRs help build devices that react to touch and force. They work well in many places.

Other Pivotal Devices

There are other tactile sensors that are important too. Each one has special jobs and good points.

- Resistive tactile sensors help map pressure. They are used in medical tools for checking how people walk.

- Capacitive tactile sensors measure pressure very accurately. They are found in medical devices that need special approval.

- Optical sensors are good for robots. They do not get messed up by electromagnetic noise.

- Strain gauge sensors check stress. They are used in load cells for exact measurements.

- Silicon-based sensors are good for new uses. They are found in devices that need to work the same way every time.

You pick the best tactile sensor for your job. Each type helps solve problems in robots, healthcare, and factories.

Tactile Sensors in Robotics and Automation

Industrial and CNC Touch Sensors

Automation Applications

Tactile sensors are used in many automated machines. These sensors help machines feel texture, softness, and pressure changes. They help robots handle materials with more care. Robots can pick up things without dropping or crushing them. Factories use tactile sensor arrays on assembly lines. These sensors help check measurements and quality. Tactile sensors also help keep workers safe. Machines can sense when a person is close. This helps stop accidents and keeps people safe.

- Tactile sensors help control robotic arms better.

- You can check if a part fits or if a surface is smooth.

- Sensors measure force and pressure during production.

CNC Machine Integration

CNC touch sensors are important in today’s factories. These sensors guide cutting tools and measure parts. Machines can check surfaces while they work. You do not have to stop the machine to inspect parts. CNC touch sensors can do many checks at the same time. This helps factories work faster and saves time.

- CNC touch sensors find small changes in materials.

- You can check for rough spots or defects.

- Sensors help change machine settings using measurement data.

CNC touch sensors make machines safer for people. Tactile sensors help stop mistakes and keep machines working well.

Medical Robotics and Haptics

Electronic Skin

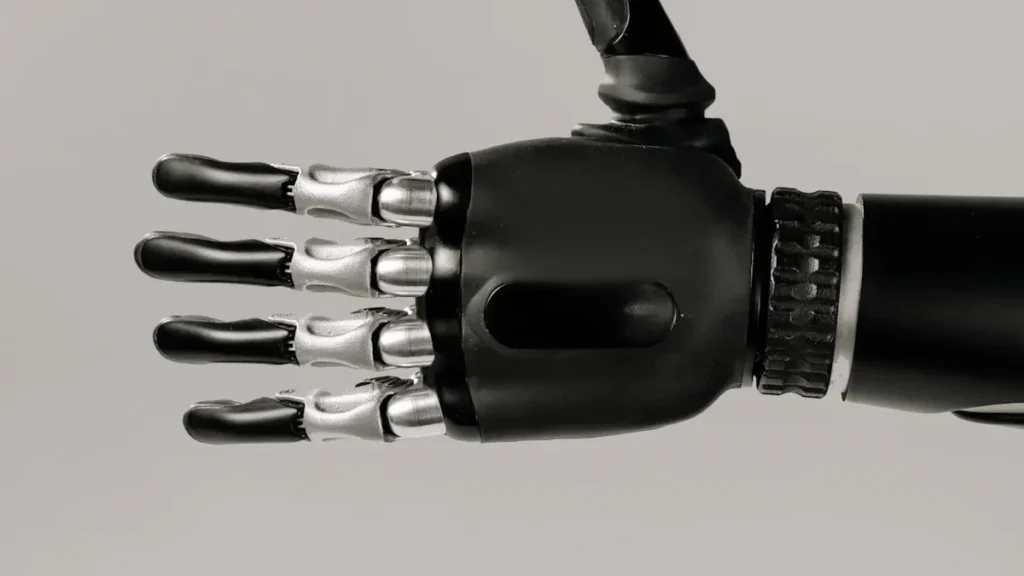

Medical robots and prosthetics use electronic skin. This technology uses tactile sensors to give robots touch. Electronic skin can sense temperature, humidity, and force. Surgeons use tactile sensors to feel tissue resistance. This helps them do better surgery. In prosthetics, electronic skin helps people feel touch again. Sensors help people move things and do daily tasks. Electronic skin is also used in rehab devices. Tactile sensors give feedback and measure progress during therapy.

- Electronic skin gives very detailed and sensitive touch.

- Sensors can sense many things at the same time.

- Tactile sensors help tell different forces apart.

Haptic Feedback

Haptic feedback uses tactile sensors to help medical robots. Surgeons use tactile sensors to guide their tools. Sensors measure force during palpation and needle use. Tactile feedback lets you feel what the robot feels. This helps you practice surgery and get better skills.

| Application Area | Description |

|---|---|

| Surgical Performance | Tactile feedback helps tell healthy from unhealthy tissue. |

| Force and Tactile Sensors | Sensors collect touch and force data for better results. |

| Feedback Modalities | You can try different feedback methods for tasks like palpation. |

You can find tactile feedback in many places:

- Palpation

- Telemanipulation

- Needle insertion

- Surgical training

- Tactile feedback helps surgeons do better in surgery.

- It makes surgical tasks more accurate and efficient.

- Tactile feedback is important for teaching new surgeons.

At UCLA’s CASIT, engineers made a balloon-based tactile feedback system for robotic surgery. This system uses FlexiForce sensors to show finger pressure. It shows how tactile sensors help surgeons control how hard they grasp.

Future electronic skin will use many kinds of sensors. These will sense physical, electrical, and chemical signals. This will help solve hard problems in medical robots and factories. Tactile sensors will help artificial skin do even more than real skin.

Tactile Sensors in Prosthetic Limbs

When you use tactile sensors in prosthetic limbs, new things become possible. These sensors let you connect with your world and make daily life easier. You can feel things, move better, and get feedback. Tactile sensors in prosthetic limbs change how you feel touch and force.

Healthcare Applications

Smart Prosthetics

Smart prosthetics have tactile sensors that help you feel touch. These sensors notice pressure, movement, and grip. You can pick up things and know how hard you are holding them. Tactile sensors stop you from dropping or crushing things. You do not have to watch your hand all the time. You can pay attention to other things.

Here is a table that explains how different sensors work in smart prosthetics:

| Sensor Type | Functionality | Advantages/Disadvantages |

|---|---|---|

| Piezoelectric Sensors | Find touch and slip signals, help you feel again | Very sensitive but need tricky circuits and break easily. |

| Elastomer-based Sensors | Measure finger moves and grip strength, fit into fake skin | Good at sensing pressure but make things more complex and cost more. |

| Conductive Fabrics | Work in many ways and need simple circuits | Cheap and easy to use for many jobs. |

You get many good things from tactile sensors in prosthetic limbs:

- Sensors collect touch data from around you.

- You get haptic feedback about your grip.

- You do not need to look as much and can do more things.

Patient Monitoring

Tactile sensors help you check your health when you use prosthetics. These sensors watch pressure and force as you move. You can see how your limb acts during different tasks. Doctors use this data to make your prosthetic more comfy and safe.

You notice some good changes:

- You can tell when you touch things or when your grip changes.

- You use cheap, custom textile sensors for feedback.

- You get smart control systems that make your prosthetic easier to use.

You walk better. You use less oxygen. You feel more sure with your prosthetic. You handle phantom limb pain better.

Rehabilitation Devices

Force Sensing in Therapy

Rehabilitation devices use tactile sensors to help you get back motor skills. These sensors measure force and movement during therapy. You get feedback that helps you learn. You find out how to control your limb more exactly.

Here is a table that shows how different devices use tactile sensors in therapy:

| Type of Device | Functionality | Enhancement in Therapy Outcomes |

|---|---|---|

| Haptic devices | Give force feedback and touch feelings | Help you learn to move and get better faster |

| Adaptive algorithms | Change therapy to fit you and add new challenges | Make therapy more fun and helpful |

| Virtual reality integration | Shows how you are doing right away | Makes you want to keep trying and work harder |

You see studies that compare haptic therapy to old ways. You notice your brain changes as you use tactile feedback. You move better and heal faster.

Safety and Efficiency

Tactile sensors make therapy safer and work better. You control things with better feedback. You avoid getting hurt when using little force. You can tell when things slip from your grip.

You get:

- Better control and feedback when handling things.

- Safer therapy sessions.

- You know when things slip, so you can train better.

You use tactile sensors to watch your progress and change your therapy. You get better results and feel safer during rehab.

Tactile sensors in prosthetic limbs help you be more independent, stay safe, and live better. You use these sensors to connect with the world in new ways.

Modern Applications and Challenges

Consumer Electronics

Touchscreens and Wearables

You use tactile sensors in your phone and smartwatch every day. These sensors help your device know when you tap or swipe. They make your screen react fast and give you feedback. Wearables use tactile sensors to track your touch and movement. You feel a buzz or vibration when you get a message or reach a goal. This feedback helps you stay connected and interested.

Here is a table that shows how tactile sensors work in popular devices:

| Application Area | Description |

|---|---|

| Smartphones | Make using your phone better with feedback for taps and swipes. |

| Wearables | Make touch easier and more fun with tactile responses. |

| Gaming Devices | Give real touch feedback, making games feel more real. |

You see these features in many new products. Pressure-sensitive screens and haptic feedback are now normal. These things make your experience smoother and more fun.

Gaming and VR

Tactile sensors change how you play games. When you use a controller or VR headset, you feel real feedback. The sensors let you feel every action, like a crash or a jump. This makes games more exciting and real. Gaming devices use tactile sensors to make vibrations and force feedback. You feel like you are in the game and react faster.

- Tactile sensors in gaming devices give you a sense of touch.

- Haptic feedback lets you feel every move and action.

- These sensors make games more fun and interactive.

Automotive and Aerospace

Safety Features

Tactile sensors help keep you safe in cars and planes. They check road conditions, tire health, and how your vehicle moves. The sensors send feedback to the system, so your car can adjust or warn you about danger. In bad weather, tactile sensors help your vehicle react to changes on the road.

- Sensors make cars and planes safer with real-time feedback.

- Vehicles use tactile sensors to adjust to road changes.

- You get better control and safer rides.

Harsh Environments

You find tactile sensors in places with heat, cold, or vibration. Car and airplane companies use these sensors because they work in tough spots. The sensors keep working even when the environment changes. This helps planes and cars work better and last longer.

Technical Barriers

Sensitivity and Durability

Not all tactile sensors work the same way. How well a sensor works depends on its design and materials. Some sensors lose accuracy if they get cracks or damage. Making sensors that last long and stay sensitive is a big challenge.

- Sensors must handle stress and still work well.

- Cracks and weather can cause problems.

- Making sensors tough and sensitive is hard.

Cost and Scalability

You might wonder why not all industries use tactile sensors. Making these sensors costs a lot because they need special materials and steps. This makes the final product more expensive. Adding sensors to old systems can be tricky and needs experts. If sensors break, you may need to replace them often, which adds to the cost.

As technology gets better, you will see more tactile sensors in use. Lower costs and better designs will help more people use these sensors every day.

Future of Tactile Sensors

You will notice many new things in tactile sensor technology soon. These changes will let you use sensors in more places and for more jobs. New materials, smarter systems, and new uses will change how you use technology.

Next-Gen Materials

Nanotechnology

Nanotechnology will make tactile sensors smaller and more sensitive. You can use nanomaterials like carbon nanotubes and silver nanowires to build flexible tactile sensors. These materials help sensors work well even when bent or stretched. Special shapes can also make sensors work better.

| Structure Type | Benefits |

|---|---|

| Interlocking Serrated Structures | Turns pressure into strain, making sensors more sensitive. |

| 2D and 3D Structures | Keeps sensors working when pulled or stretched. |

You can use materials like PDMS, Teflon, hydrogels, and liquid metals to make sensors that work in many ways. Some sensors use triboelectric nanogenerators to power themselves. This means some sensors do not need batteries.

Self-Healing Sensors

In the future, you will use self-healing sensors that fix themselves after damage. These sensors use special materials that can repair cracks or breaks. You will find these sensors in wearables and medical devices. They will last longer and work better in tough places.

You will also see new designs like biomimetic microstructures and auxetic-structured 3D-printed materials. These help sensors sense many signals at once. You can use them for health checks and feeling textures. Auxetic structures let you make sensors that fit each person.

AI and Machine Learning

Adaptive Sensing

Artificial intelligence will help you get more from tactile sensors. Machine learning can help you tell textures apart, find edges, and control grip. Deep learning can help sensors notice slip or guess how they will bend.

| Application Area | Methodology Used | Outcome/Benefit |

|---|---|---|

| Texture Classification | Neuromorphic tactile sensing | Very clear touch sensing |

| Edge Detection | Machine learning | Better feedback for gripping |

| Slip Detection | Deep learning | Better control when moving things |

| Dynamics Modeling | 3D data and feedback | Can guess how sensors will bend |

Predictive Maintenance

You can use AI to watch how sensors work over time. Machine learning can help you find problems before they break. This helps you keep your tactile sensor systems working longer and with fewer surprises.

You can also use AI to make sensors more accurate. Neural networks help you spot shapes and patterns very well.

Expanding Fields

Space Exploration

Tactile sensors will help you explore space. Robots with tactile sensors can handle fragile samples and tools on other planets. You can use these sensors to check equipment and make repairs in space.

Human-Machine Interfaces

You will use tactile sensors in new ways to connect with machines. Biomimetic microstructures will help you build better human-machine interfaces. These sensors can sense many things at once, making your interactions easier and more natural.

You will see tactile sensors in many fields: – Manufacturing: Sensors help you check quality and find defects. – Robotics: Tactile sensors give robots better control and touch. – Healthcare: You get better prosthetics and surgical robots. – Automotive: Sensors help you stay safe and comfortable in your car.

The future of tactile sensor technology will give you more control, better feedback, and new ways to interact with the world.

Tactile sensors started as simple machines. Now, they are advanced tools in many areas. Over time, new designs made sensors work better. Each period brought better tactile feedback. The table below shows what helps progress and what problems still exist:

| Driving Forces | Challenges and Restraints |

|---|---|

| Robotics and Automation | Cost and High-End Solutions |

| Automotive Safety | Durability in Harsh Environments |

| Miniaturization and Flexibility | Standardization and Data Complexity |

| Demand for High Sensitivity | N/A |

Today, you find tactile sensors in phones and sports gear. They are also used in aerospace. Tactile sensor technology keeps improving. You will see sensors help robots and medical tools work better. Smart devices use tactile sensors to give feedback. Tactile feedback changes how you use machines. In the future, sensors will be smaller and more sensitive. You will see them in new places. Tactile sensing will help connect people and technology.

FAQ

What is a tactile sensor?

A tactile sensor lets a device sense touch or pressure. You use it in robots, phones, and medical tools. It helps machines feel and respond to force.

How do force sensing resistors (FSRs) work?

You press on an FSR. Its resistance drops as you apply more force. The device measures this change and tells you how much force you use.

Where do you find tactile sensors in daily life?

You find tactile sensors in smartphones, gaming controllers, cars, and smartwatches. They help your devices respond to touch and pressure.

Why do robots need tactile sensors?

Robots need tactile sensors to grip objects safely. You help robots pick up, hold, and move things without dropping or crushing them.

Can tactile sensors improve prosthetic limbs?

Yes. Tactile sensors let you feel pressure and touch with a prosthetic limb. You get better control and feedback for daily tasks.

What makes SOUSHINE FSRs special?

SOUSHINE FSRs give you reliable force measurement. You can use them in many shapes and sizes. They last long and use little power.

Are tactile sensors expensive?

Some tactile sensors cost more than others. You choose based on your needs and budget. Prices depend on design, material, and features.

How do you choose the right tactile sensor?

You look at your project’s needs. Think about size, sensitivity, and where you will use the sensor. Pick one that fits your application best.