Call us: +86-137-2353-4866

SOUSHINE’s force sensing resistor is a top product for thin pressure sensors in 2025. Other companies like Tekscan, Respicefinem, DSM, and NextFlex also make these sensors. These sensors help wearable electronics and robots do more things. This makes the industry grow fast.

- Thin-film pressure sensors for robots made USD 1.42 billion in 2024.

- The market will grow by 8.7% each year from 2025 to 2033. It will be worth USD 3.03 billion by 2033.

| Contribution | Description |

|---|---|

| Enhanced Functionality | Thin pressure sensors make devices work better. |

| Improved Human-Robot Interaction | They help people and robots work together. |

| Real-Time Data Processing | These sensors let devices use data right away. |

| Development of Smart Devices | They help build smart and connected devices. |

Thin pressure sensor technology keeps changing how force sensing works in wearables and robots.

Table of Contents

Key Takeaways

Thin pressure sensors help wearables and robots work better. They make these devices more useful and efficient. The market for thin pressure sensors will grow a lot. It may reach USD 3.03 billion by 2033. Flexible sensors can bend and stretch easily. This makes them great for many uses in wearables and robotics. SOUSHINE’s force sensing resistors can be changed to fit many needs. They are good for things like health monitoring. New materials and designs make thin pressure sensors more sensitive and strong. When sensors connect with IoT, they send data fast. This helps people make quick decisions. Picking the right sensor means looking at sensitivity, strength, and if it works with your device. In the future, sensors will do even more jobs. They will measure things like temperature and humidity too.

Top Thin Pressure Sensor Innovations

Leading Models in 2025

Thin pressure sensors have changed a lot lately. SOUSHINE, Tekscan, Respicefinem, DSM, and NextFlex are top companies in 2025. Each company brings something new to the market. SOUSHINE makes force sensing resistors that measure force very well. Tekscan’s sensors work great in hospitals and factories. Respicefinem makes thin film sensors for smart gadgets. DSM builds sensors that can handle tough places. NextFlex uses printed electronics to make flexible sensors for wearables and robots.

Sensors are now smaller because of miniaturization and nanomaterials. This lets them fit into tiny devices. Designers can make new products for wearables and medical tools. AI in sensors helps devices use data faster and react quickly. These upgrades help doctors and cars make fast decisions.

| Company Name | Distinguishing Features |

|---|---|

| SOUSHINE | Customizable force sensing resistors for many applications |

| Tekscan | Sensors for medical and industrial use |

| Respicefinem | Thin film sensors for smart electronics |

| DSM | Sensors for harsh environments |

| NextFlex | Printed flexible pressure sensors for wearables and robotics |

Key Advantages

Flexible pressure sensors work better than old ones. They can be used in many places and give accurate data. The newest sensors use MEMS technology and flexible electronics. These things help sensors last longer and work in more places.

- Sensors now use printed circuit boards, not wire coils. This makes them more reliable and easier to make.

- New sensors have temperature compensation and different frequency outputs. These features let sensors work in more ways.

- Flexible pressure sensors can bend and stretch. This is good for wearables and robots.

| Feature | Previous Generations | 5th Generation Pressure Sensor |

|---|---|---|

| Coil Design | Wire wound on plastic | Integrated coil on printed circuit board |

| Reliability | Moderate | Greater reliability |

| Manufacturing Benefits | Limited | Obvious manufacturing benefits |

| Advanced Features | Basic functionality | Temperature compensation, frequency output |

| Accuracy and Performance | Standard | Superior accuracy and performance |

| Application Versatility | Limited | Excellent for several applications |

Thin pressure sensors now have many new uses. They work in smart gadgets, robots, and medical tools. Sensors help devices collect data and react fast. Flexible pressure sensors let designers make products for many different needs.

Importance in Wearable Electronics and Robotics

Enhancing Wearable Electronics

Thin pressure sensors help wearable electronics work better. They make it easier for people to use their devices. These sensors track movement and check health signs. They are also used in sports science. Many smartwatches and fitness bands use pressure sensors. These sensors measure your pulse and how you breathe. They react very fast, in about 1 millisecond. They can notice even tiny changes in pressure. The sensors stay accurate after being used thousands of times.

| Feature | Description |

|---|---|

| Sensitivity | Ultrahigh sensitivity of 1.46 × 10^6 kPa−1 |

| Response Time | Fast response time of 1 ms |

| Stability | Works well over 2000 compression-release cycles |

| Detection Limit | Detects pressure as low as 10 Pa |

| Breathability | Allows air flow, with 93.2% breathability |

| Applications | Health monitoring, robotics, human-machine interfaces, sports science |

These features help wearable electronics do more things. Smart clothing uses sensors to check pressure on the body. This makes clothes more comfortable. Devices can watch how people move and send this data to apps. This helps people learn about their health and activity. Biomedical sensors in wearables also help doctors care for patients by checking important health signs.

Advancing Robotics Applications

Robots use thin pressure sensors to work better and safer. These sensors help robots feel things and hold them right. They can sense pressure on many shapes and surfaces. Robots use this information to not drop or break things.

- Thin, flexible sensors can measure pressure when bent.

- They work best if bent more than 2 cm.

- If bent less than 2 cm, they are less accurate, so designers need to plan for this.

Robots that help people, like exoskeletons, use pressure sensors to keep users safe and comfy. Designers can change how wearable robots fit by using sensor data. This makes it easier for people and machines to work together. Pressure sensors in robots also help them feel touch, so they are safer around people.

Expanding Use Cases

Thin pressure sensors are now used in many new ways. Wearable health devices were used 30% more from 2023 to 2025. Cars use these sensors to help drivers stay safe. Some new sensors can check pressure, temperature, and humidity at the same time. This lets wearable electronics do more jobs with fewer parts.

| Emerging Use Case | Description |

|---|---|

| Wearable Health Monitoring Devices | More devices use thin-film sensors for health tracking |

| Advanced Driver-Assistance Systems | Cars use sensors for better safety features |

| Multi-Parameter Sensing | Over 35% of new sensors measure pressure, temperature, and humidity |

| Flexible Sensor Designs | Medical wearables use flexible sensors, supported by new regulations |

Now, people can use these sensors to control devices by pressing or tapping. This makes technology simpler to use. Pressure sensors in wearables and robots are being used more. This helps people and machines connect in new ways.

Thin Pressure Sensor Technology Comparison

Capacitive Sensors

Capacitive sensors find pressure by checking changes in electrical capacitance. They work well in many places and can handle hot or cold temperatures. These sensors also survive short times with too much pressure. They can measure from almost no pressure to very high pressure. Many companies use this technology in their products.

- Capacitive sensors can notice very tiny pressures, as small as 3 Pa. They react fast when the pressure changes. These sensors have little hysteresis and repeat well. The biggest error when used many times is about ±14%. Their sensitivity is high, about 22.5 times more than some other sensors. They can measure from 0 up to 400 kPa.

Capacitive sensors are used in wearables, finger sensors, and breathing monitors. They last a long time and are very accurate. This makes them a good choice for flexible pressure sensors.

Resistive Sensors (FSRs)

Resistive sensors are also called force sensing resistors or FSRs. They change resistance when you press on them. SOUSHINE’s FSRs are a top example of this kind. These sensors are small and do not cost much. Many designers use them to make devices work better and easier to use.

- FSRs fit inside small gadgets. They help lower the price of pressure systems. Flexible sensors in this group can be made in many shapes and sizes.

FSRs are used in robots and wearable gadgets. They help people use devices by sensing touch and pressure. Their bendy design helps make smart clothes and robot hands.

Piezoelectric Sensors

Piezoelectric sensors make electricity when you press on them. They use materials like PVDF, BTO, and III-Ns. These materials are safe, bendy, and stable for wearables. The table below lists some common materials and what they are like:

| Material | Properties | Suitability for Wearables |

|---|---|---|

| PZT | Great piezoelectric properties, but has lead and is toxic | Not good for wearables because it is unsafe |

| ZnO | Safe, but not stable with chemicals | Better for electronics that do not last long |

| PVDF | Safe, stable, and bendy | Good for wearables |

| BTO | Safe, stable, and bendy | Good for wearables |

| III-Ns | Safe, stable, and bendy | Good for wearables |

Piezoelectric sensors work well where things move a lot. They are often used in wearables that need to react fast. These sensors are also used in advanced robots that need to sense pressure quickly and correctly.

Note: Each sensor type has its own special strengths for thin pressure sensors. Designers pick the best one for their wearable or robot based on what they need.

Hybrid and Flexible Sensors

Hybrid and flexible sensors have changed how engineers make wearables and robots. These sensors mix the best parts of different sensor types. They help devices work in more places and for more people.

Hybrid sensors have both stiff and bendy parts. This design gives them the accuracy of stiff sensors and the comfort of bendy ones. Flexible sensors can bend and stretch. They fit on curved surfaces and move with the body. Many engineers use them in smart clothes, fitness bands, and soft robots.

Hybrid and flexible sensors help new devices work better. They make devices more comfortable and easier to use.

Key benefits of hybrid and flexible thin pressure sensors:

- Flexible sensors can fit many shapes and surfaces.

- They give comfort to people who wear them.

- Stiff parts give strong and accurate readings.

- Hybrid designs mix comfort and accuracy.

- Flexible soft sensors work in many places.

- They keep users safe and comfortable.

- Hybrid sensors last longer and handle more stress.

Flexible sensors use materials like polymers and thin films. These materials let the sensor bend without breaking. Some sensors use printed electronics. This makes sensors thin and light. Hybrid sensors often use both printed and regular parts.

New wearable systems need sensors that are fully flexible and fit the body. They must also do more than one job. Some hybrid sensors can measure pressure, temperature, and movement at the same time. This helps lower the number of parts in a device.

| Feature | Hybrid Sensors | Flexible Sensors |

|---|---|---|

| Comfort | High | Very high |

| Accuracy | High | Moderate |

| Durability | High | Moderate |

| Adaptability | High | Very high |

| Multifunctionality | Yes | Sometimes |

Engineers use hybrid and flexible sensors in many areas. Wearable health monitors use them to track heart rate and movement. Soft robots use them to sense touch and pressure. These sensors also help in smart shoes, gloves, and medical patches.

Hybrid and flexible sensors will change the future of wearables and robotics. They help devices fit better, last longer, and do more jobs. As technology grows, these sensors will become even more important.

Material and Fabrication Advances

Flexible Substrates

Flexible substrates have changed how engineers make thin pressure sensors. These materials let sensors bend and stretch without breaking. New materials help sensors work better in many ways. Some materials form an electrical double-layer capacitance. This makes sensors more sensitive. Other materials help sensors respond faster and more evenly. New microstructure designs make sensors more accurate and tough. These changes let sensors find a wider range of pressures.

| Performance Indicator | Description |

|---|---|

| Sensitivity | Sensors are more sensitive because of new capacitance. |

| Linearity | Better materials make sensors respond more evenly. |

| Response/Recovery Time | New designs help sensors react and recover faster. |

| Durability | Stronger materials make sensors last longer. |

| Accuracy | Improved microstructures make sensors more accurate. |

| Detection Range | New materials help sensors find more pressure levels. |

Flexible substrates let sensors fit on curved surfaces. This is good for wearables and human-machine interfaces. Designers can now make sensors that work in many places.

Printed and Polymer Composite Sensors

Printed and polymer composite technology makes sensors faster to build. Engineers use 3D printing to make complex sensor shapes. They mix piezoelectric ceramic particles with polymers. This creates composite materials for sensors. These materials give sensors high voltage output and strong sensitivity. When engineers change the sensor shape, it works better on curved surfaces.

| Aspect | Details |

|---|---|

| Material System | Piezoelectric composite made from ceramic particles and polymers. |

| Technology Used | 3D printing helps make complex sensor shapes. |

| Piezoelectric Voltage Constant | 220.2 × 10−3 Vm‧N−1 |

| Piezoelectric Sensitivity | 30 mV·kPa−1 after changing the shape. |

| Application | Sensors can measure pressure on curved surfaces. |

These advances help sensors work in smart clothes and medical patches. They also help new human-machine interfaces that need sensors to fit many shapes.

Integration with IoT

Connecting sensors with IoT is now very important. Flexible pressure sensors can link to smart homes and wearables. Researchers study how the thickness of the resistive layer and substrate type change sensor behavior. They find the best designs for sensitivity and strength.

| Aspect | Details |

|---|---|

| Sensor Type | Flexible pressure sensors for wearables and smart homes. |

| Key Focus | Making sensors work better and fit with IoT. |

| Research Contributions | Studied how layer thickness and substrate affect sensors. |

| Findings | Found the best designs for sensitivity and durability. |

IoT lets sensors send data right away. This helps devices react quickly to people. It also helps doctors and smart homes watch things from far away.

Tip: Better materials and new ways to make sensors help them work better. These sensors are now more important in human-machine interfaces and smart devices.

Product Reviews: Top Thin Pressure Sensors

SOUSHINE Force Sensing Resistors (FSRs)

Performance

SOUSHINE Force Sensing Resistors (FSRs) work well in many places. They can measure small forces with high sensitivity. The sensors are thin and flexible, so they fit in wearables and robots. They last through over 10 million presses. These sensors are good for sensing light touches or repeated pressure. The price is low, so they are great for big projects.

- They sense small forces with high sensitivity.

- They last through more than 10 million presses.

- Their thin, flexible shape fits many devices.

- They are cheap for large projects.

- They work well in wearables, medical tools, and robots.

Usability

Engineers say SOUSHINE FSRs are easy to use in many products. The thin shape lets them fit in small spaces. Designers can pick from many shapes and sizes. This helps when making custom devices. The sensors use little power, so batteries last longer. People use them in smart clothes, medical patches, and robot hands.

Unique Features

SOUSHINE FSRs are special because they are flexible, strong, and save money. The company lets you customize the sensors. Their team helps from design to final product. These things help engineers make new products that need good pressure sensing.

Tekscan FlexiForce Series

Performance

The Tekscan FlexiForce Series gives steady pressure readings in many places. These sensors work in both medical and factory settings. They handle many pressure levels and react fast to changes. The sensors keep working after lots of use, so they are good for long-term devices.

Usability

Tekscan FlexiForce sensors can be hard to use in wearables and robots. The design must balance how it works and how it feels. Sometimes, the sensors make devices heavier or bigger. This can change how a device feels or moves. Engineers must plan to keep devices comfy and easy to use. The sensors also need systems that can change feedback for each user or job.

- Good design is needed for comfort.

- Adding sensors may make devices bigger or heavier.

- Systems should let users change feedback.

Unique Features

Tekscan FlexiForce sensors can sense many pressure levels. They work in many fields, like health and factories. The sensors can be used in custom feedback systems. This helps when making devices that need to sense touch or force in special ways.

Respicefinem Thin Film Sensor

Performance

Respicefinem Thin Film Sensors work well in tough places. They handle quick pressure changes and do not lose their shape. The sensors keep working even with strong shakes or bumps. This makes them useful where other sensors might stop working.

Usability

Engineers use Respicefinem sensors in devices that measure pressure in special gases or high heat. The sensors fit in systems that need strong and steady parts. Their design helps keep devices safe and working in hard places.

Unique Features

| Feature | Description |

|---|---|

| Strong Build | Made with materials that resist shakes and bumps |

| High Pressure Tolerance | Handles fast pressure changes without bending |

| Good for Special Gases | All-welded diaphragm stops gas from getting through |

| Works at High Temperatures | Can work at high heat because there are no organic glues |

Respicefinem Thin Film Sensors are known for being strong and working in extreme places. They help engineers fix problems in advanced industries.

DSM Pressure Sensor

Performance

The DSM Pressure Sensor works very well in robots. It can notice small changes in force. It reacts faster than human skin. The sensor keeps working even when stretched. It can sense how hard a robot is gripping. It also finds jitter signals in soft robots. The table below lists important performance facts:

| Metric | Value |

|---|---|

| Sensitivity | 1.08 kPa-1 |

| Response Time | Faster than human skin |

| Recognition Accuracy | Over 94% |

| Stability under Stretching | Still works with 10 kPa change at 50% stretch |

Usability

Engineers put DSM Pressure Sensors in soft robots and wearables. The sensor can stretch up to 50% and still be right. It fits into bendy systems and changes shape easily. The sensor works well where things move and bend a lot. Designers use it for jobs that need fast and steady force sensing.

- The sensor fits on curved shapes.

- It works in soft robot hands and wearable patches.

- It stays accurate when bent or stretched.

Unique Features

DSM Pressure Sensors are special because they can stretch and stay steady. They find both steady and moving forces. The sensor helps soft robots hold things and feel movement. It keeps being accurate after many uses and stretches.

- Very sensitive and steady

- Stretches a lot without problems

- Great for soft robot jobs

- Can sense gripping force and jitter signals

NextFlex Printed Sensor

Performance

NextFlex Printed Sensors help make flexible and wearable gadgets. They use printed electronics to be thin and light. The sensor works in health trackers and wearable medical tools. It lets devices collect data wirelessly and supports tiny systems.

- The sensor fits in small gadgets.

- It helps with wireless health checks.

- It works in flexible hybrid electronics.

Usability

Designers use NextFlex Printed Sensors in smart wearables and health tech. The sensor goes with flexible materials, so it is easy to add to clothes or patches. It helps make cheap health tracking systems. The sensor can send data wirelessly, making it easier for users.

- The sensor fits in wearable patches and smart clothes.

- It can send data without wires.

- It helps build small health devices.

Unique Features

NextFlex Printed Sensors mix flexible materials with health tech. They help speed up the use of flexible hybrid electronics in health. The sensor makes low-cost, wireless medical wearables possible. It supports small platforms for health tracking.

- Helps make cheap, wireless medical wearables

- Supports building small health tracking devices

- Mixes flexible materials with health tech

Performance and Usability Comparison

Sensitivity and Accuracy

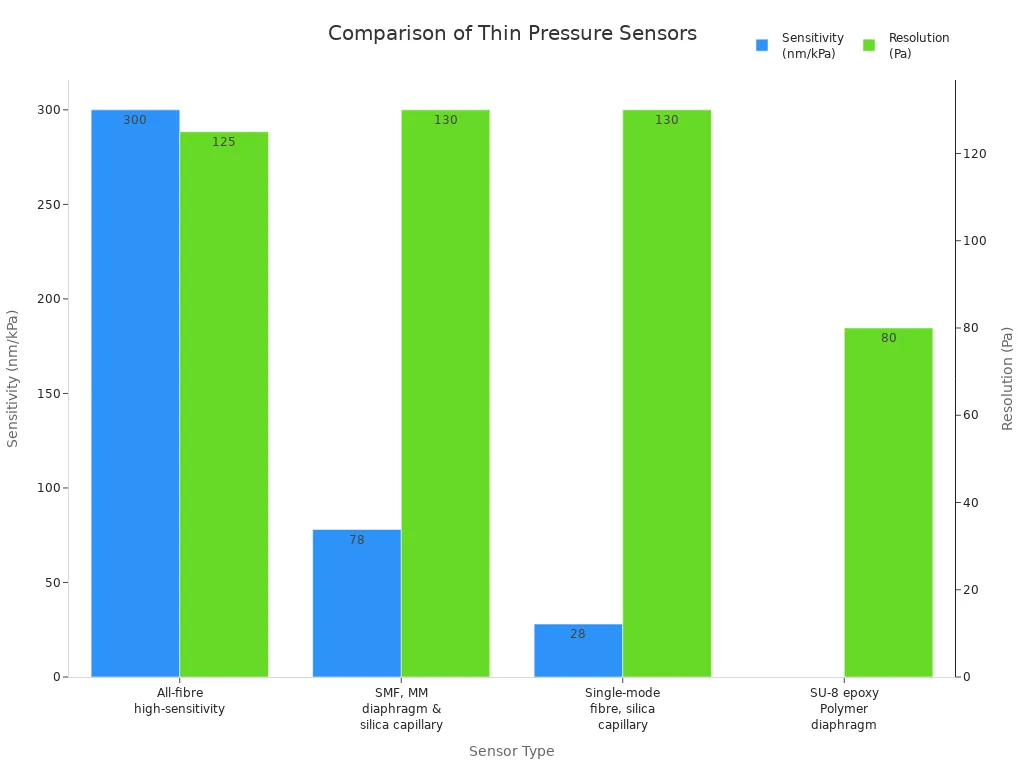

Sensitivity and accuracy are very important for thin pressure sensors. These features help devices notice small changes in force. Engineers use different materials and shapes to make sensors work better. Some sensors have fiber or polymer layers to sense pressure more. The table below shows how top sensors compare in sensitivity and accuracy:

| Sensor Construction and Materials | Pressure Range (kPa) | Sensitivity (nm/kPa) | Resolution (Pa) |

|---|---|---|---|

| All-fibre high-sensitivity pressure sensor | 3.4 | 300 | 125 |

| SMF, MM diaphragm & silica capillary | 15 | 78 | 130 |

| SMF, Capillary & Epoxy adhesive film | 0–70 | 0.257 | N/A |

| Single-mode fibre, silica capillary | 1–1.6 | 28 | 130 |

| Silk Fibroin, Silica Capillary | 12.3 | N/A | 127 |

| SU-8 epoxy Polymer diaphragm | 0–700 | 0.00293 | 80 |

Some sensors with all-fiber designs are very sensitive. Others, like SU-8 epoxy polymer diaphragms, can measure a wide range but are less sensitive. Engineers pick the right sensor for each device’s needs. For example, health monitors need sensors that find tiny pressure changes. Robots may need sensors that cover a bigger range but do not need as much sensitivity.

Materials change how sensitive a sensor is. For example, airlaid paper and carbon black sensors reach over 7.12 kPa−1 sensitivity. Sensors with copying tissue paper and graphite reach about 0.14 kPa−1. These differences help engineers choose the best sensor for each job.

Sensors with high sensitivity and accuracy help devices give better feedback and collect more useful data.

Durability and Flexibility

Durability and flexibility help sensors last longer and work in more places. Thin pressure sensors often use bendy materials. These materials let sensors bend and stretch without breaking. Flexible sensors are common in electronic skin and wearable devices.

- Flexible pressure sensors are light and sensitive.

- They work well in wearable flexible sensing devices.

- The thin-film structure gives sensors mechanical stability.

- Sensors keep working even when bent or pressed many times.

Engineers design sensors to handle stress and changes in the environment. Good materials and strong designs help sensors stay stable. This is important for devices used every day or in tough places. For example, sensors in smart clothes must survive many washes and movements. Sensors in robots must handle lots of bending and stretching.

Picking the right materials and using strong ways to make sensors helps them last longer. This lets sensors work for a long time, even in hard conditions.

Sensors that last longer and bend easily help make better wearable and robotic devices.

Integration and Compatibility

Integration and compatibility show how well sensors fit into different devices. Some sensors work best in health care and wearables. Others fit better in robots or smart buildings. The table below shows how top companies design sensors for different uses:

| Application Area | Companies | Key Features |

|---|---|---|

| Healthcare & Wearables | FlexiSense, BioFlex | Biocompatible, high-sensitivity sensors for continuous health monitoring |

| Industrial Automation | PolySense, DynamiX | Rugged, reliable sensors for harsh environments and real-time data delivery |

| Soft Robotics & Prosthetics | StretchTech, AdaptiSense | Flexible, stretchable sensors for soft, deformable structures |

| Smart Infrastructure & IoT | FlexiTech Innovations, VarioSense | Scalable, connected sensors for large-area monitoring and smart city applications |

Sensors for health care must be safe for the body and track health signs all day. Sensors for robots and factories must be tough and give real-time data. Sensors for soft robotics need to stretch and move with the device. Sensors for smart cities must connect easily and cover large areas.

Good integration and compatibility help sensors work in many new devices and systems.

Cost and Availability

Thin pressure sensors have become more common in many industries. Companies now make these sensors in large numbers. This helps lower the price and makes them easier to find. The market for thin-film pressure sensors was worth about USD 1.5 billion in 2023. Experts expect it to reach around USD 3.2 billion by 2032. This growth shows that more people want better pressure sensors for cars, medical tools, and electronics.

- The thin-film sensor market reached USD 5.35 billion in 2024.

- It may grow to USD 5.71 billion in 2025, with a growth rate of 6.69%.

- The global pressure sensor market was about USD 20.6 billion in 2024.

- It could reach USD 26.3 billion by 2030, growing at 4.1% each year.

- The pressure sensor market may rise from USD 13.07 billion in 2025 to USD 17.7 billion by 2030.

Many companies offer thin pressure sensors at different prices. Some sensors cost less because they use simple materials. Others cost more because they use special designs or advanced features. Large projects can save money by buying sensors in bulk. Custom sensors may cost more, but they fit special needs.

Availability has improved as more companies join the market. Buyers can find sensors for many uses, such as wearables, robots, and cars. Online stores and direct sales from companies make it easy to order these sensors. Some companies also offer support for design and integration.

Tip: When choosing a sensor, buyers should check the price, how easy it is to get, and if it fits their project. They should also look at the total cost, including setup and support.

Thin pressure sensors help improve pressure measurement systems in many fields. As demand grows, prices may drop, and more options will appear. This helps engineers and designers build better products for everyone.

Choosing the Right Thin Pressure Sensor

For Wearable Electronics

Picking the best thin pressure sensor for wearables takes careful thought. Devices must fit the body and move with the user. They also need to give good data. Engineers want sensors with high electrical conductivity and flexibility. These features help sensors send signals fast and bend without breaking. Sensors must work with many materials used in wearables. Stability and reliability are important because people wear these devices every day.

The table below lists what matters most when picking sensors for wearables:

| Criteria | Description |

|---|---|

| Electrical conductivity | High electrical conductivity is needed for fast signals. |

| Mechanical flexibility and stretchability | Materials must bend and stretch but still conduct electricity. |

| Compatibility with substrates | Materials should work well with different bases and making methods. |

| Stability and reliability | Sensors must last a long time in many conditions. |

| Adhesion and interface compatibility | Good stickiness helps sensors stay in place during use. |

| Scalability | Materials should be easy to get for making lots of sensors. |

| Biocompatibility | For medical uses, materials must be safe for the body. |

Flexible pressure sensors meet many of these needs. They go into smartwatches, fitness bands, and smart clothes. These sensors help track movement and check health. They also help people and machines work together. In medical sensors, biocompatibility is very important. Engineers also check if the sensor can be made in large numbers. Good stickiness helps sensors stay put while being used. All these things help wearables work well and stay accurate.

For Robotics

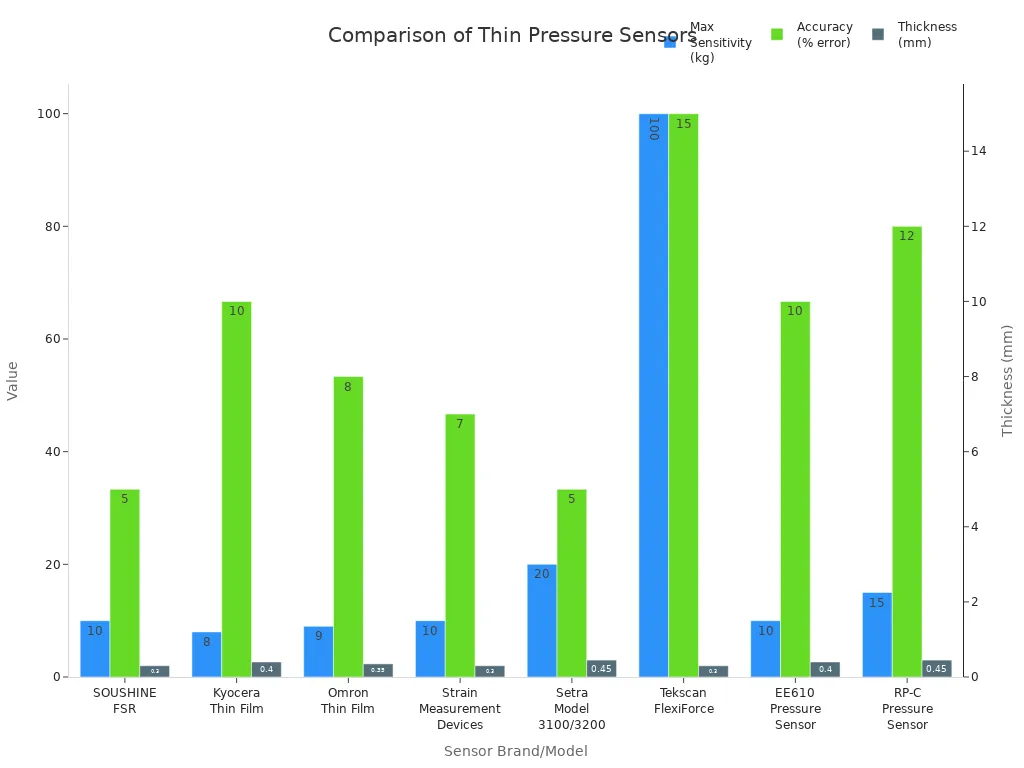

Robots need sensors that handle many forces and react fast. Engineers look for sensors that are thin, bendy, and correct. The table below compares top thin pressure sensors for robots:

| Sensor Brand/Model | Sensitivity & Range | Accuracy & Repeatability | Thickness & Flexibility | Response Time | Medical Suitability | Industrial Suitability | Certifications |

|---|---|---|---|---|---|---|---|

| SOUSHINE FSR | 20g-10kg | +/-5% (single tube) | 0.3mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| Kyocera Thin Film | 30g-8kg | +/-10% | 0.4mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| Omron Thin Film | 25g-9kg | +/-8% | 0.35mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| Strain Measurement Devices | 20g-10kg | +/-7% | 0.3mm, flexible | <10ms | Good | Excellent | ISO 9001, ANSI |

| Setra Model 3100/3200 | 50g-20kg | +/-5% | 0.45mm, rigid | <10ms | Fair | Excellent | ISO 9001, ANSI |

| Tekscan FlexiForce | 10g-100kg | +/-15% | 0.3mm, flexible | <10ms | Good | Excellent | ISO 9001, EHEDG |

| EE610 Pressure Sensor | 20g-10kg | +/-10% | 0.4mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| RP-C Pressure Sensor | 30g-15kg | +/-12% | 0.45mm, rigid | <10ms | Fair | Excellent | ISO 9001, ANSI |

SOUSHINE FSR is special because it is thin, flexible, and accurate. Robotics engineers use these sensors in robot hands and soft robots. Fast response times help robots feel touch and pressure changes. Certifications like ISO 13485 and FDA show these sensors are safe and high quality. Other brands like Kyocera and Omron also make good flexible sensors. Engineers pick sensors based on what each robot needs, like range, accuracy, and how much it can bend.

Future Trends

Anticipated Advances

Thin pressure sensors will change a lot in five years. Companies and scientists want to make these sensors better for wearables and robots. Some big changes are coming:

- Sensors will get more sensitive and flexible. They will find smaller forces and bend more without breaking.

- Sensors will work with IoT. They will send data to networks right away.

- New materials will help sensors last longer and work in more places.

- Sensors will measure more things, like temperature or movement, not just pressure.

These changes will make wearable electronics smarter and more helpful. Sensors will fit in smaller gadgets and give better data. Pressure systems will be more accurate and dependable. Many companies will use these sensors in different industries.

Note: New sensor designs will help engineers make better human-machine interfaces. People will control devices with simple touches or moves.

Impact on Wearables and Robotics

Thin pressure sensors will change how wearables and robots work. As sensors get smaller and better, they will fit in more devices. Wearables will track health and movement in more detail. Biomedical sensors will help doctors get better patient information. Human-machine interfaces will be easier to use and react faster.

Robots will also get better with these new sensors. Robots will use them to hold things gently. In hospitals, robots will help doctors do surgeries with more care. More hospital jobs will use robots as sensors give real-time feedback. Pressure systems will help robots change their grip and move better.

Consumer electronics will change too. Smartwatches and fitness bands will use thin sensors for a better user experience. Human-machine interfaces in these gadgets will react faster and more accurately. This means wearable electronics will be used more in daily life.

Tip: Engineers should look for new sensor technology. These changes will shape the future of wearables, robots, and human-machine interfaces.

Thin pressure sensors work well and bend easily in 2025. SOUSHINE FSRs are best for wearables and robots. Tekscan, Respicefinem, DSM, and NextFlex make good sensors too.

- SOUSHINE FSRs go in health monitors and robot hands.

- Tekscan and DSM sensors help in factories and medical tools.

- NextFlex sensors are used in bendy wearables.

Pick a sensor by looking at how sensitive it is, how long it lasts, and if it fits your device. Thin pressure sensor technology will keep getting better and help smart devices talk and react faster.

FAQ

What is a thin pressure sensor?

A thin pressure sensor can feel force or pressure on its top. It turns this feeling into an electrical signal. Engineers put these sensors in wearables and robots.

How do SOUSHINE FSRs work?

SOUSHINE FSRs change their resistance when you press them. The sensor checks this change and sends the data to a device. This lets the device know about touch or pressure.

Where can people use thin pressure sensors?

Thin pressure sensors are found in smartwatches and fitness bands. They are also in medical patches, robot hands, and car safety systems. These sensors help gadgets sense touch and movement.

Why do robots need thin pressure sensors?

Robots use thin pressure sensors to feel things they touch. The sensors help robots hold items gently and not break them. This makes robots work better with people and objects.

Are thin pressure sensors safe for skin contact?

Most thin pressure sensors are made from safe materials. Companies test their sensors to make sure they are safe for skin. Always check for safety certifications before using them on your body.

Can thin pressure sensors measure more than pressure?

Some thin pressure sensors can also check temperature or humidity. These sensors help devices gather more information with fewer parts.

How long do thin pressure sensors last?

Thin pressure sensors can be used many times. Some, like SOUSHINE FSRs, last through millions of presses. How long they last depends on the material and how you use them.