Call us: +86-137-2353-4866

Many industries trust the best force sensor manufacturers in 2025. These companies are known for utilizing advanced technology, being reliable, and working all over the world. Companies like Honeywell, FUTEK, SOUSHINE, and TE Connectivity have high standards for quality, ensuring every high quality sensor delivers exceptional performance.

- Companies like Honeywell, FUTEK, SOUSHINE, and TE Connectivity have high standards for quality, ensuring every high quality sensor delivers exceptional performance.

- The market also has leaders like Alps Alpine, Flintec, and Vishay Precision Group. They focus on Force Sensing technology that accurately measures the applied force to give real-time feedback and keep things safe across a variety of applications. Their expertise is crucial in the broader field of test and measurement.

Picking a trusted force sensor manufacturer helps make sure products are good. It also helps with automation and makes things safer in healthcare and cars, opening the door for novel force measurement applications.

Table of Contents

Key Takeaways

- Top force sensor makers like TE Connectivity, Honeywell, SOUSHINE, and FUTEK are leaders. They make a reliable and high quality sensor. They also use new and smart advanced technology.

- Force sensors are very important in a variety of applications. These include healthcare, cars, robots, and factories, often working alongside pressure sensors and temperature sensors. They help make things safer, more exact, and more automatic.

- Picking the right force sensor starts with knowing your test and measurement needs. Think about the applied force range, where it will be used, its size, and how exact it must be.

- Choose companies that give good help and quick delivery. They should offer ways to customize, perhaps with a complete sensor module for easy integration, and follow strict quality rules and certifications.

- Different companies are best at different things. Some make small and exact sensors for medical and robot use. Others make strong sensors for hard jobs in factories.

- The development of novel force measurement applications is booming. Force sensors help robots feel and act safely. They help cars have safety features. They let medical tools do careful work with accuracy.

- Price is important, but the cheapest sensor may not be best. Think about the total value, like quality, help, and how long it will last.

- Good force sensor makers spend money on research and new ideas. They make smart and connected sensors for changing industry needs.

Top Force Sensor Manufacturers

TE Connectivity

Overview

TE Connectivity is a top company in force sensor technology. The company has been making reliable products for a long time. Its sensors help machines and devices measure force very well.

Strengths

TE Connectivity works hard to make new and better products. The company spends money on research to make sensors work better. Its products follow tough rules for quality. Many people trust TE Connectivity because it always gives good results and has many products.

Technologies

TE Connectivity uses special materials and smart designs in its sensors. The company makes sensors that can work in tough places. Its sensors can send both analog and digital signals. TE Connectivity also makes sensors for very exact measurements in factories and cars.

Reputation

Many experts say TE Connectivity is one of the best sensor makers. The company sells products all over the world. Customers like its helpful support and fast delivery. TE Connectivity is often named as a top sensor company.

Honeywell

Overview

Honeywell is a famous company for force sensors. The company helps many areas, like planes, hospitals, and factories. Honeywell’s sensors help machines work safely and well.

Strengths

Honeywell is known for making safe and strong products. The company checks its sensors to make sure they are very good. Honeywell also has many types of sensors for different jobs.

Technologies

Honeywell uses old and new ways to make sensors. Its force sensors can measure both small and big forces. Many sensors have digital parts to connect easily. Honeywell also makes sensors that work in very hot or cold places.

Reputation

Honeywell is one of the top force sensor companies in the world. Many engineers and companies trust its sensors. The company’s long history and focus on quality keep its good name.

SOUSHINE

Overview

SOUSHINE is an important company in the force sensor market. The company makes Force Sensing Resistors, called FSRs. SOUSHINE’s sensors help measure force and pressure in many new devices.

Strengths

SOUSHINE gives customers many good things. The company has good prices, so more people can use FSRs. SOUSHINE lets customers pick different shapes, sizes, and features. The company checks each sensor to make sure it works well and lasts long. SOUSHINE helps customers from the start of design to after they buy the product.

Technologies

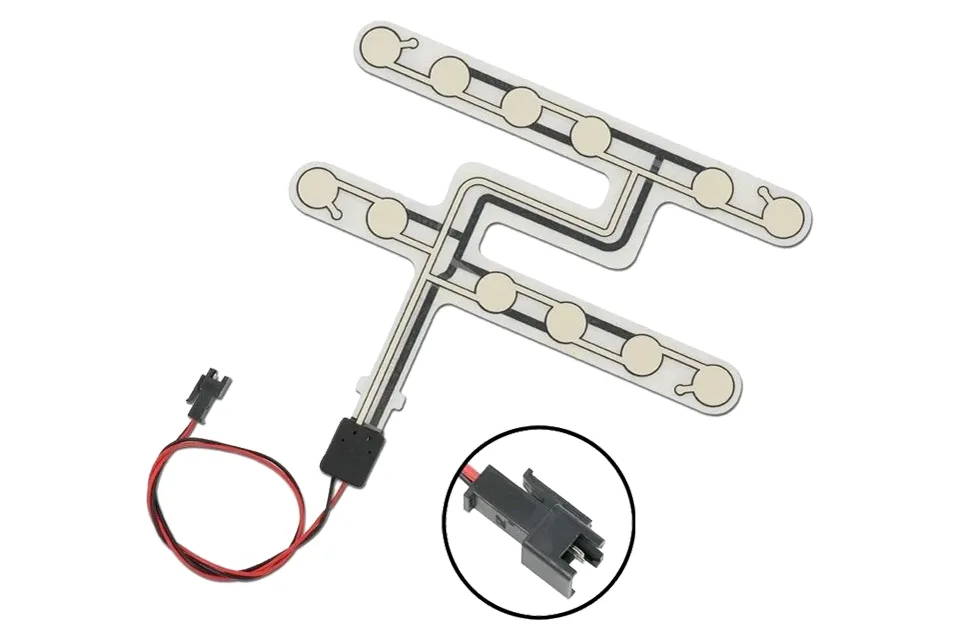

SOUSHINE’s FSRs use piezoresistive ideas. Each sensor has a bendy base and a special layer that carries electricity. When someone pushes on the sensor, its resistance changes. This change helps measure force correctly. SOUSHINE also makes sensor arrays that collect data from many spots at once. These arrays are good for jobs that need to see force in detail.

SOUSHINE’s FSR technology is special because it has:

- Good prices without losing quality

- Many ways to customize sensors

- Careful checks for good performance

- Full help for customers from start to finish

Reputation

SOUSHINE is one of the top force sensor companies in 2025. Many companies pick SOUSHINE for its good sensors and strong support. The company’s new ideas and careful measurements make it stand out around the world.

Thorlabs

Overview

Thorlabs is a big name in photonics and measurement. The company makes many force sensors for labs and factories. Scientists and engineers use Thorlabs tools to measure force in experiments.

Strengths

Thorlabs has lots of sensors and parts to pick from. The company ships orders quickly and helps customers with questions. People like Thorlabs because its products are simple to use. The instructions are clear and easy to follow. Thorlabs can also make special sensors for different needs.

Technologies

Thorlabs uses strong materials and smart designs in its sensors. Many sensors use strain gage or piezoelectric technology. These sensors can find tiny changes in force very well. Thorlabs adds digital screens and data saving features for better results.

Reputation

Thorlabs is trusted as a top force sensor maker. Many researchers and engineers pick Thorlabs for its good service. The company stays ahead by making new things and helping customers.

Dytran

Overview

Dytran is a famous force sensor company with over 40 years in business. The company makes sensors for measuring force and pressure that change quickly. Dytran works with planes, cars, and testing companies.

Strengths

Dytran builds tough sensors for hard jobs. The company can fix and check sensors to keep them working. Dytran has important certificates like AS9100 and ISO17025/A2LA. These show the company cares about quality.

Technologies

Dytran uses special sensors like IEPE accelerometers and charge mode sensors. Its products have strong metal cases made from titanium or stainless steel. Dytran’s sensors can handle high heat and rough places.

Dytran’s best force sensor products are:

Product Model Sensor Type Key Performance Specifications Notable Features 3055D Series IEPE Accelerometer Low noise; Resonant frequency over 25 kHz; Sensitivity ±5%; Frequency response 1 Hz to 10 kHz Titanium case; Base isolation; Side connector; Models for high temperatures 3056D Series IEPE Accelerometer Low noise; Resonant frequency over 25 kHz; Sensitivity ±5%; Frequency response 1 Hz to 10 kHz Titanium case; Base isolation; Top connector; Models for high temperatures 3335C High-temp Charge Mode Works up to +1200°F (+649°C); Sensitivity 1-2 pC/g; Sealed Inconel 600 case; Patented Silver Window™ Made for tough places; Electrical isolation; Lock-wire hole; Hard-line cable 3168D2 Single-axis IEPE Quartz Sensitivity 10 mV/g; Frequency range 1 Hz to 10,000 Hz (±3 dB); Sealed stainless steel case Filters; Faraday shield; Thru-hole design; Teflon® cable

Reputation

Dytran is known for making strong and high-quality sensors. The company helps customers by fixing and checking sensors. Dytran’s certificates and long history show it cares about good service. Joining HBK should help Dytran give even better support. Many people trust Dytran as a top force sensor company.

Vishay Precision Group

Overview

Vishay Precision Group, or VPG, is a top force sensor maker. The company has been measuring force for over 50 years. VPG works with cars, hospitals, and factories.

Strengths

VPG sells many kinds of force sensors and weighing tools. The company can make special sensors and help put them in place. VPG’s products are known for being correct and working well.

Technologies

VPG uses strain gage technology in many sensors. These sensors can measure force very exactly. VPG also makes weighing systems for trucks and machines.

VPG follows strict rules for safety and quality. The company meets REACH and RoHS rules to keep electronics safe. Most VPG products do not use lead, which is better for the planet. VPG’s UK factory has IATF 16949:2016 certification for car parts. The company also uses ISO 9001 rules for checking sensor quality.

Reputation

VPG is seen as one of the best force sensor makers in the world. The company’s focus on safety and quality has earned trust from many people. VPG’s certificates and long work in the field make it a good choice for measuring force.

FUTEK

Overview

FUTEK is a top force sensor maker in 2025. The company makes sensors for many jobs. These jobs include medical, robots, and space. FUTEK’s sensors help people and machines measure force very well.

Strengths

FUTEK is good at making tiny and smart sensors. The company works with doctors and robot makers. FUTEK helps with special projects and hard problems. Their sensors fit in small spaces. They can measure both pulling and pushing.

Technologies

FUTEK has made new force sensor technology. The company makes very small but strong sensors. Many of these help doctors and engineers in small places. Some are used in robot surgery tools. FUTEK adds digital parts to connect to computers and robots.

The table below shows some of FUTEK’s best force sensors and what they do:

| Sensor Model | Description | Key Technological Breakthroughs and Features |

|---|---|---|

| QLA414 Nano | Ultraminiature force transducer | Measures force at the tip of robotic surgery tools; high capacity-to-size ratio; used in minimally invasive surgery |

| LSB205 | Miniature load cell | Measures tension and compression (1 to 100 lb); compact; handles off-center loads; controls robotic tool motion |

| QTA141 | Miniature torque sensor | Very accurate torque feedback; improves accuracy to 0.25% or better; helps control delicate surgeries |

FUTEK also makes sensors that are easy to clean for hospitals. The company can make lots of sensors at once.

Reputation

FUTEK is well known in the force sensor world. Many doctors and engineers trust FUTEK’s products. The company’s focus on small, smart sensors keeps it ahead.

ATI Industrial Automation

Overview

ATI Industrial Automation is a top force sensor company. The company makes sensors that help robots feel force in many ways. ATI works with cars, planes, and electronics.

Strengths

ATI is known for working with other companies. It teams up with FANUC, a big robot company. This helps robots use ATI’s sensors and FANUC’s software together. ATI helps customers set up systems and learn how to use them.

Technologies

ATI makes sensors that measure force from all sides. These sensors help robots build, polish, and test things. ATI’s sensors work in hard places and last a long time. The company adds smart features like AI to make sensors better.

Reputation

ATI has made force sensors for almost 30 years. Many people trust ATI’s sensors because they are strong and correct. In 2023, ATI made sensors for tough places and bought a company that uses AI. This shows ATI cares about new ideas and quality. Their sensors help robots do jobs better and safer.

Interface Inc.

Overview

Interface Inc. is a famous force sensor company with over 50 years of work. The company makes sensors to measure force, torque, and weight. Interface helps energy, space, and building companies.

Strengths

Interface has many products and helps customers a lot. The company fixes, checks, and makes special sensors. Interface’s team can make sensors for special jobs. They also teach and help people with ForceEdu.

Technologies

Interface makes sensors for labs and tough places like oil rigs. The company’s products include load shackles, small displays, and Bluetooth data loggers. These tools help people measure force and save data easily.

The table below lists some of Interface’s main products and what they do:

| Product Name | Distinguishing Features | Application / Use Case |

|---|---|---|

| ISHK-B Bow Type Crosby™ Cabled Load Shackles | Submersible, rugged, measures tension in mooring systems | Offshore mooring, structural checks |

| 9325 Portable Sensor Display | Supports six calibration ranges, user units, handheld, PC toolkit | Portable display for load cells and torque sensors |

| BSC4D-BT Portable 4-channel Bluetooth Data Logger | Bluetooth, multi-channel, portable | Remote data recording, field force measurement |

| BX6-BT Portable 6-Channel High-Speed Bluetooth Data Logger | High-speed, Bluetooth, six channels | Multi-channel force measurement, field testing |

Reputation

Interface Inc. is trusted for good products and service. The company’s lab checks sensors to make sure they work right. Interface helps people all over the world with repairs and design. Many people pick Interface for its strong support and products.

Methode Electronics

Overview

Methode Electronics is a top company in sensor technology. The company makes advanced tools to measure force and current. Methode Electronics helps many fields, like cars and factories.

Strengths

Methode Electronics has many good points:

- The company makes new sensor technology for real problems.

- It cares about safety and how well things work in cars and machines.

- Methode Electronics grows by joining new markets, like e-bikes and green energy.

- The company works with OEMs to make custom solutions.

Technologies

Methode Electronics has made big steps in sensor technology:

- The company uses magneto-elastic sensors in tow load systems. These sensors give real-time data about force when towing. This helps drivers stay safe and in control.

- Methode Electronics uses eddy-current sensors to sense gear positions. This helps European car makers know where gears are.

- The company’s sensors are also used in brake pedal force and payload sensing.

- Methode Electronics helps factories with load pins and force sensors for cranes, elevators, and robots.

Industries that use Methode Electronics sensors include:

- Automotive (tow load, brake pedal, payload)

- Industrial machinery (cranes, elevators, escalators)

- Medical equipment (MRI, scanners)

- Renewable energy systems

- Robotics and automation

- Railway and forklifts

Reputation

Methode Electronics is known for new ideas and being reliable. Many car and factory companies trust its sensors for safety and performance. The company’s move into new markets, like e-bikes, shows it can change and lead in sensor technology.

Adin Robotics

Overview

Adin Robotics makes force and torque sensors for robots. The company designs sensors that help robots feel touch and move in three ways. Adin Robotics helps with factory robots and service robots.

Strengths

Adin Robotics is special for many reasons:

- The company made the first 10 mm subminiature 6-axis force/torque sensor with built-in signal processing.

- Its sensors are small and simple to use, so they fit in tiny robots.

- Adin Robotics leads big projects to make custom sensors for service robots.

Technologies

Adin Robotics uses smart technology to help robots sense better:

- The company uses capacitance measurement to make thin and scalable sensors. This lets them make lots of small and thin sensors.

- Its sensors let robots feel force and torque in all directions. This helps robots do jobs that people used to do.

- Adin Robotics made a dual-mode proximity tactile sensor (APS series). This sensor can sense a crash before it happens and slow or stop the robot, making work safer.

Key features of Adin Robotics sensors:

- 6-axis force/torque sensing

- Built-in signal processing

- Capacitance measurement for thin design

- Proximity tactile sensing for safety

Reputation

Adin Robotics is now a leader in robot sensing. The company’s sensors help robots work safely and well. Many people in robotics know Adin Robotics for its focus on new ideas and safety in automation.

Force Sensor Applications

Industrial

Factories use force sensors to make work safer and better. These sensors help machines check if parts fit right. They also measure how hard a robot pushes. Force sensors control how much weight is on a conveyor. Many industries need force sensors to watch and control machines. Aerospace, oil and gas, construction, and farming all use them. Workers can find problems early with these sensors. This helps keep machines working well.

The table below lists how force sensors are used in factories in 2025 and how they affect the market:

| Industrial Applications for Force Sensors in 2025 | Description / Examples | Market Size and Growth |

|---|---|---|

| Automotive | Brake systems, steering, seat detection, motor speed, gear knob, assembly checks, suspension force, gasket monitoring | Major driver; demand grows with electric and self-driving cars |

| Medical and Healthcare | Robotic surgery, prosthetics, medical monitors | More robot-assisted surgery and precision medicine need sensitive sensors |

| Consumer Electronics | Devices needing force measurement | Growing sector |

| Manufacturing, Aerospace, Oil & Gas, Construction, Agriculture | Monitoring, control, testing, measurement | Monitoring and control lead due to need for precision and safety |

| Market Size (2025) | N/A | USD 10 billion globally |

| Forecast CAGR (2025-2032) | N/A | 5.7% CAGR |

| Projected Market Size (2032) | N/A | USD 14.74 billion |

People pick force sensors because they are correct and dependable. These sensors help companies waste less and make better products.

Robotics

Robots use force sensors to feel things and hold objects. In 2025, robots in factories, hospitals, and homes need these sensors for better control. AI makes force sensors smarter so robots can learn and change how they move. This helps robots work safely near people.

- AI helps robots use force sensors to decide fast.

- Collaborative robots use sensors to keep people safe.

- Robots mix force, sight, and touch data to grab things better.

- Small sensors fit in tiny robot hands for careful jobs.

- Wireless sensors let robots move more freely.

Robots in factories use force sensors for building, welding, and checking things. In hospitals, robots use them for surgery and helping patients. These changes show force sensors make robots safer and smarter.

Automotive

Cars and trucks use force sensors in many ways. These sensors check brake pressure and help with steering. They also know if someone is sitting in a seat. New cars, like electric and self-driving ones, need more sensors for safety and comfort. Force sensors help airbags work at the right time. They also help with advanced driver-assistance systems.

Car companies want sensors that work in hard places and give good results. As more cars use automation, the need for good force sensors goes up. The car industry is still a big reason the force sensor market grows.

Medical

Hospitals and clinics use force sensors in many ways. Doctors and nurses need tools that give quick and clear feedback. Medical devices with force sensors help them do their jobs better. These sensors are used for surgery, patient care, and testing.

Robotic surgery uses force sensors to guide tools inside the body. The sensors tell the robot how much pressure it uses. This helps doctors avoid hurting tissue. Surgeons can work with more control and safety. Prosthetic limbs also use force sensors. The sensors help the artificial hand or leg feel pressure. This lets people pick up things without dropping or crushing them.

Medical beds and wheelchairs use force sensors to check if a patient moves. The sensors warn nurses if a patient needs help. Blood pressure monitors and infusion pumps use sensors to measure force. This keeps medicine flowing at the right speed.

Note: Force sensors in medical devices must measure very exactly. Doctors trust these sensors to keep patients safe.

Some hospitals use sensor arrays to watch many patients at once. These arrays help track movement and pressure points. This can stop bedsores and other problems. Force sensors also help in labs. They measure how much force a scientist uses in tests.

New trends in medical force sensors include smaller size and wireless data. Smaller sensors fit inside tiny tools. Wireless sensors send data to computers without wires. These changes help doctors and nurses work faster and safer.

Manufacturer Comparison

Features

Sensor manufacturers give different features to help people pick the best sensor. Some companies make sensors that are very accurate. Others build sensors that work well in hard places. Many companies now add smart ways to connect and make sensors easy to use. The table below shows how top sensor makers do in accuracy, strength, and how they connect:

| Manufacturer | Accuracy | Durability | Connectivity / Application Fit |

|---|---|---|---|

| FUTEK LSB302 | High | Moderate | Small size, good for robots and careful work |

| Honeywell FSS-SMT | Moderate | High | Strong, works in tough places and big machines |

| TE Connectivity FX1901 | Moderate | High | Sensitive and strong, good for factory machines |

FUTEK is known for sensors that measure very exactly and are small. Honeywell makes sensors that last a long time in rough places. TE Connectivity makes sensors that are both sensitive and strong for factories. Some new companies, like UltraSense Systems, use special piezoelectric technology. Their sensors can set themselves up and work with car systems like LIN or CAN. This makes them easy to use in cars and helps keep parts safe. These features help people get good data and connect sensors to new machines.

Strengths

Each sensor company has its own strong points. Some have been making sensors for many years. Others use new ideas or focus on special jobs. The table below shows what each company is best at:

| Manufacturer | Key Strengths | Supporting Details |

|---|---|---|

| Interface Inc. | Very exact, special strain gauge, lots of experience | Over 50 years making sensors, biggest maker of spoke-type sensors |

| Honeywell | Many products, knows planes, very big company | Over 100 years in business, makes many plane parts, good at control systems |

| FUTEK | Tiny sensors, very exact, used in medicine and robots | Fits in small spaces, used in surgery tools and robots |

| SOUSHINE | Custom FSRs, flexible, great customer help | Many shapes and sizes, checks every sensor, helps from start to finish |

| Adin Robotics | 6-axis force/torque, thin, safe | Small for robots, has signal processing, senses touch for safety |

Sensor companies compete to be the best. They spend money to make sensors that set themselves up and show data right away. Big companies can make more products and help more people. Small companies focus on special jobs, like off-road trucks or electric cars. This mix lets people find the best sensor for their needs.

Note: Sensors that measure very exactly and come with good help stand out. People should pick the company that matches what they need for the best results.

Choosing a Force Sensor Manufacturer

Needs Assessment

Picking the right force sensor manufacturer starts with knowing what you need. Every job is different and needs its own kind of sensor. First, users should decide what they want the sensor to do. For example, a factory might use sensors to watch the assembly line. A hospital might use sensors in medical machines.

Some important questions to ask are: What force range does the sensor need? Does it have to work in very hot or cold places? How exact and sensitive does it need to be? Does it need to give real-time data? What size and shape should the sensor be?

Doing a good needs check helps stop problems later. It also helps you pick the best sensor for the job. Users should talk with everyone involved, like engineers and workers, so nothing is missed.

Tip: Make a list of all your needs before talking to any manufacturer. This makes it easier to compare choices and not forget anything important.

Capabilities

After you know your needs, look at what each force sensor manufacturer can do. Not every company has the same features or quality. Some things to think about are:

- Compatibility: The sensor should work with your current systems.

- Calibration and Standards: Good companies check their sensors and follow rules.

- Customization: Some jobs need special shapes or features. Companies that offer custom sensors can help more.

- Durability: Sensors should handle drops and rough use. A weak sensor will not last in a busy place.

- Environmental Resistance: Sensors should keep working if there is dust, water, or chemicals.

- Form Factor: The sensor’s size and shape must fit your job. Thin and bendy sensors, like FSRs, are good for small spaces.

- Repeatability: Good companies make sure every sensor works the same way. This stops problems in making things.

- Measurement Range and Sensitivity: The sensor should measure the right amount of force and notice small changes.

- Certifications: Look for ISO 9001 or RoHS. These show the company cares about safety and quality.

- Lead Times and Delivery: Fast delivery helps you finish projects on time.

- After-Sales Service: Help with setup and fixing problems protects your money.

- Warranty: A good warranty helps you feel safe about your choice.

A table can help you see what each manufacturer can do:

| Capability | Why It Matters |

|---|---|

| Compatibility | Stops problems when setting up |

| Calibration | Makes sure data is correct |

| Customization | Fits special job needs |

| Durability | Works in tough places |

| Environmental Resistance | Keeps working in hard settings |

| Repeatability | Always works the same way |

| Certifications | Shows safety and quality |

| After-Sales Service | Helps sensors last longer |

Support

Support from the manufacturer is very important for long-term use. Good support means you get help with problems, training, and repairs. Users should check if the company gives:

- Fast answers to questions

- Easy-to-read guides and manuals

- Training for workers

- Help with setup and starting

- Quick repair or replacement

Good support helps fix problems fast. It also keeps sensors working well for a long time. Some companies visit your site or help online. This saves time and keeps things running.

Note: Picking a force sensor manufacturer with strong support can stop costly delays and help everything work smoothly.

Cost

Cost is important when picking a force sensor manufacturer. Buyers should not just look at the price. The cheapest sensor is not always the best deal. Sensor makers have different prices for different features and support. Buyers need to think about all the costs, not just the sensor price. There are other costs like setup, calibration, and fixing sensors. Some companies include extra help in their price. Others charge more for support or upgrades.

A table can help you see the costs:

| Cost Factor | What to Consider |

|---|---|

| Sensor Price | Upfront cost for each sensor |

| Setup Fees | Cost to install and connect sensors |

| Calibration | Fees for making sure sensors are accurate |

| Maintenance | Regular checks and repairs |

| Support | Help from the company |

| Upgrades | Cost to add new features |

Some buyers want sensors that measure very exactly. These sensors cost more because they use better technology. But they can save money by stopping mistakes and waste. Precision sensors help make better products and avoid big problems.

Buyers should ask if there are discounts for buying a lot. Many companies give better prices for big orders. Some have special deals for schools or labs.

It is smart to ask for a full price quote before buying. The quote should show all costs, like shipping and taxes. This helps you compare different companies.

Tip: Always check if the price comes with support and warranty. Good support can save money if something goes wrong.

Some companies sell cheaper sensors, but they may not last as long. They might not measure as well. Top sensor makers use better materials and check quality more. This can mean a higher price, but also better sensors and fewer replacements.

The best sensor companies in 2025 are known for new ideas and great help. Each company is good at something special. Some make sensors that measure very exactly. These are used in medicine or robots. Other companies build sensors for hard places, like factories. People should think about what they need before picking a company. Choosing the right one helps things work better and keeps them safe.

Tip: Look at the tables to see which company is best for your job.

FAQ

What is a force sensor?

A force sensor tells you how much force or pressure is used. Many jobs use these sensors to check weight or touch. They help machines work safely and the right way.

Why do manufacturers choose high precision measurement?

Manufacturers want very exact measurements for better products. This helps them make fewer mistakes and waste less. Top force sensor companies care about being precise.

How do sensor manufacturers test quality?

Sensor makers check every sensor before sending it out. They use special tools to test if sensors are correct and strong. Many companies follow strict rules to make sure sensors work well.

Where are force sensors used most?

Factories, robots, cars, and hospitals use force sensors a lot. These sensors help control machines and keep things safe. Many gadgets also use force sensors for touch and feedback.

What makes a top force sensor manufacturer stand out?

A top force sensor company is known for good products and support. They use new technology and give custom solutions. Fast delivery and lots of experience help people trust them.

Can force sensors measure very small forces?

Yes, some force sensors can find very tiny forces. These sensors are made with special designs for high accuracy. Many jobs need this detail for testing and control.

How do I choose the right force sensor manufacturer?

First, write down what you need. Check if the company has the right sensor for your job. Look for good help, quick shipping, and proven quality. Many people also look at prices and reviews.

Are all force sensors the same?

No, force sensors come in many shapes and sizes. Some measure big forces, others measure small changes. Different companies use different ways to make sensors. Always pick the sensor that matches your job.