Call us: +86-137-2353-4866

The top five thin film pressure sensor products for 2025 are special for different reasons. SOUSHINE is very good at new ideas in pressure sensing. Setra Systems Model 3100 gives very accurate results for factories. Hilitand Flexible Film Sensor is small and fits in tight spaces. Interlink Electronics FSR 400 Series works for many different jobs. FSRTEK Thin Film Sensor is a good deal for the price. These sensors help engineers pick the best one for their needs.

Key Takeaways

- SOUSHINE sensors are bendy and very sensitive. They are great for projects that need exact and steady pressure readings.

- Setra Systems Model 3100 works well in hard factory places. It is very accurate and built to last a long time.

- Hilitand sensors are tiny, light, and react quickly. They are good for wearables and small gadgets.

- Interlink Electronics FSR 400 Series can be used in many ways. It gives steady and trusted pressure readings.

- FSRTEK sensors work well and do not cost much. They are good for simple home and gaming gadgets.

- Picking the best sensor depends on what your project needs. You should think about accuracy, size, pressure range, and cost.

- Thin film coatings and materials change how sensitive, strong, and bendy a sensor is.

- Helpful customer support and trusted sensors make sure your device works well for a long time.

Top 5 Thin Film Pressure Sensor Products

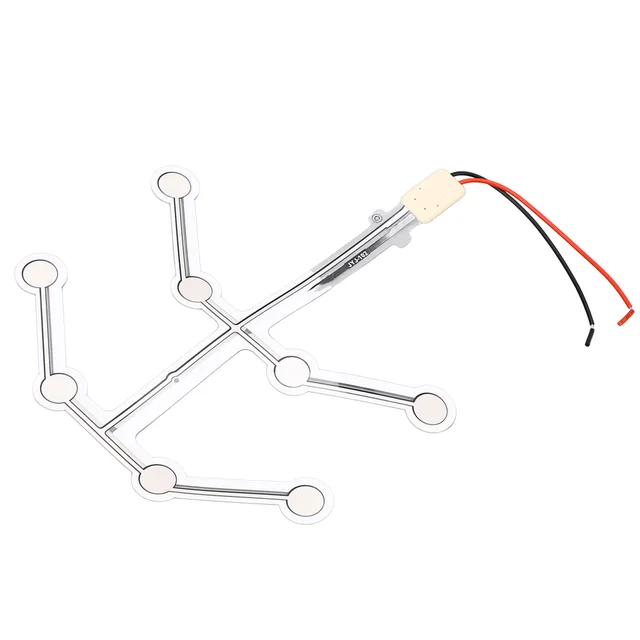

SOUSHINE SBR Film Pressure Sensor

SOUSHINE SBR Film Pressure Sensor is known for its new way to find force and pressure. This thin film pressure sensor has a bendable base and a special material that helps it measure well. The sensor’s resistance changes when you press on it. This lets engineers get exact data right away. SOUSHINE’s sensors work in many things, like factory machines, cars, and touch screens. The flexible shape fits in small spots and can bend around curves. SOUSHINE also makes sensor arrays for jobs that need lots of data. The company uses strong materials and makes sure the sensor works well every time. This makes it a great pick for projects that need to be very sensitive and steady.

Setra Systems Model 3100

Setra Systems Model 3100 is a top choice for tough jobs in factories. This thin film pressure sensor is very accurate, with only a small error. It can measure from 75 to 32,000 psi. The sensor is made of stainless steel, so it lasts a long time. It has IP67 sealing to keep out water and wet air. Setra gives you different ways to get the data, like current or voltage. The sensor shows both pressure and temperature in voltage. It does not use oil, so it does not leak or get too hot. The sensor is small, less than 1 inch wide, so it fits in many places. It has protection if you wire it wrong and works in very hot or cold places. The sensor can handle very high pressure, up to 40 times its normal range. It is made in a super clean room and is checked for heat changes. The sensor almost never fails, with a rate under 0.1%. It is strong against shaking and rough use. It also blocks out electrical noise, so it works well. Setra gives you good value for the price, so many companies pick this sensor for hard jobs.

Note: Setra Systems Model 3100 is great for tough jobs. It is very accurate, strong, and gives you different ways to get data. This makes it perfect for machines that need to work well in hard places.

Hilitand Flexible Film Sensor

Hilitand Flexible Film Sensor is small and easy to use for measuring pressure. This sensor has a thin, bendy base that fits in tiny or odd spaces. It can bend and wrap around things, so it works well in wearables and small gadgets. Hilitand’s sensor reacts fast to pressure changes and gives steady results. It is light, so it does not make devices heavy. This helps when space and weight are important. Engineers like this sensor because it is simple to put in and gives good data. The bendy design lets people make cool new products in electronics and health tools. Hilitand’s focus on being useful and easy to use makes this sensor a good pick for projects that need a small thin film pressure sensor.

Interlink Electronics FSR 400 Series

Interlink Electronics FSR 400 Series is known for being useful and dependable. This thin film pressure sensor can be used in many fields. Engineers put these sensors in cars, medical tools, factory machines, and robots. The FSR 400 Series helps find when people touch electronic things. It can tell if a press was on purpose or by mistake. This helps keep people safe and gives better control.

The FSR 400 Series makes it easy for people to use devices. It checks how hard something is pressed and gives feedback. In medical tools, these sensors can see if someone is in a bed or chair. They also help find the middle of a force by using more than one sensor. In safety tools, the sensors know if someone is holding or just touching, which can lock the device.

Engineers use these sensors to find if tubes or pumps are blocked by checking pressure. The FSR 400 Series can also be used in other jobs that need to find changes in force. Its bendy shape lets it fit in many devices. The sensors work the same way every time and react fast to changes. This makes them a good pick for projects that need quick and correct pressure checks.

The FSR 400 Series works well in both easy and hard devices. It can be used in many places, so engineers like to choose it.

FSRTEK Thin Film Sensor

FSRTEK Thin Film Sensor is a good choice if you want to save money. This thin film pressure sensor works well in lots of devices. Many engineers pick FSRTEK because it is not too expensive and works well. The sensor fits in home electronics, smart wearables, and small factory tools.

FSRTEK sensors have a bendy base, so they are easy to put in small spaces. The sensors change their resistance when you press on them. This helps devices check pressure the right way. FSRTEK sensors are used in touch panels, game controllers, and small medical tools. The sensors keep working well even after being used many times.

FSRTEK makes sensors that are simple to use and add to devices. The sensors react quickly and give steady data. This helps devices work smoothly for users. FSRTEK Thin Film Sensor is a good deal and works well in many jobs.

FSRTEK Thin Film Sensor gives engineers a smart choice for projects that need good pressure sensors without spending too much.

Thin Film Pressure Sensor Comparison Table

Key Specifications

The table below shows the main things about the top five thin film pressure sensors. These facts help engineers look at how accurate, thick, or thin each sensor is, and what pressure it can measure.

| Sensor Name | Accuracy | Thickness/Size | Pressure Range |

|---|---|---|---|

| SOUSHINE SBR Film Pressure Sensor | High (±1 mmHg) | Ultra-thin, flexible | 0–100 mmHg (linear) |

| Setra Systems Model 3100 | 0.25% of span | <1 inch diameter | 75–32,000 psi |

| Hilitand Flexible Film Sensor | High sensitivity | Thin, bendable | 0–10 kg |

| Interlink Electronics FSR 400 | Moderate accuracy | Flexible, compact | 0–10 kg |

| FSRTEK Thin Film Sensor | Good repeatability | Thin, flexible | 0–10 kg |

Setra’s sensor has special thin film layers on a steel base. SOUSHINE’s FSRs use a special layer that helps them work really well. Hilitand’s sensor uses a tiny material base, so it bends and reacts fast.

Unique Features

Each sensor has something special that makes it different. The table below shows what makes each one stand out.

| Sensor Name | Unique Features | Construction/Material | Application Suitability |

|---|---|---|---|

| SOUSHINE SBR Film Pressure Sensor | Sensor arrays, linear force-resistance, flexible design | Proprietary thin film coatings | Industrial, automotive, touch panels |

| Setra Systems Model 3100 | High-pressure range, IP67, oil-free, robust build | Stainless steel thin film coatings | Industrial, harsh environments |

| Hilitand Flexible Film Sensor | Nanomaterial substrate, ultra-thin, fast response | Flexible nanomaterial | Wearables, compact devices |

| Interlink Electronics FSR 400 | Versatile, detects touch and force, fast feedback | Flexible polymer | Medical, robotics, consumer devices |

| FSRTEK Thin Film Sensor | Cost-effective, easy integration, reliable output | Thin flexible film | Consumer electronics, gaming |

SOUSHINE’s thin film layers help the sensor bend and last longer. Setra’s thin film layers make the sensor strong in tough places. Hilitand’s tiny material base lets it work well in small gadgets.

Price and Value

How much a sensor costs and what you get for the price is important. The table below shows what each sensor offers for its price.

| Sensor Name | Price Range | Value Proposition |

|---|---|---|

| SOUSHINE SBR Film Pressure Sensor | $–$$ | High performance, flexible, reliable |

| Setra Systems Model 3100 | $$ | Industrial-grade, durable, precise |

| Hilitand Flexible Film Sensor | $–$$ | Affordable, compact, high performance |

| Interlink Electronics FSR 400 | $ | Versatile, easy to use, good performance |

| FSRTEK Thin Film Sensor | $ | Budget-friendly, solid performance |

SOUSHINE’s sensor is a good mix of price and how well it works. Setra’s sensor costs more but works best in hard places. Hilitand and FSRTEK give good results for less money. Interlink’s sensor is easy to use and works well for many jobs.

Engineers should pick a sensor that fits their project and budget. The best sensor depends on how accurate it needs to be, where it will be used, and how much money you can spend.

Product Reviews

SOUSHINE SBR Film Pressure Sensor

Overview

SOUSHINE SBR Film Pressure Sensor is easy to notice in the market. The company uses new technology to make sensors that give very exact force and pressure numbers. These sensors have a bendy base and a special layer that carries electricity. This design helps the sensor work well in many places. SOUSHINE makes sure each sensor keeps working well for a long time.

Features and Specs

SOUSHINE SBR Film Pressure Sensor has a thin and bendy base. The sensor checks force by changing its resistance when you press it. The way force and resistance match helps engineers get clear data. The sensor can be used in sensor arrays for harder jobs. It can measure pressure from 0 to 100 mmHg and is very accurate at ±1 mmHg. The special thin film coating helps the sensor last longer and work better.

Pros and Cons

Pros:

- Works well in many places

- Bendy design fits lots of uses

- Can be used in sensor arrays

- Gives exact and steady numbers

Cons:

- Costs more than some other sensors

Best Application

SOUSHINE SBR Film Pressure Sensor is best for projects that need to work well and be very sensitive. Engineers use these sensors in factory machines, cars, and touch screens. The bendy shape also works in medical tools and robots.

Setra Systems Model 3100

Overview

Setra Systems Model 3100 is made for people who need strong sensors. The sensor uses stainless steel and thin film coatings. This makes the sensor last a long time and work well.

Features and Specs

Setra Model 3100 can measure pressure from 75 to 32,000 psi. The sensor is small, less than 1 inch wide. It has IP67 sealing to keep out water and dust. The sensor gives both current and voltage data. It does not use oil, so it is safer and works better.

Pros and Cons

Pros:

- Works well in tough places

- Can measure a lot of pressure

- Strong with stainless steel

- Gives different types of data

Cons:

- Costs more than other sensors

Best Application

Setra Systems Model 3100 is best for factories and big machines. Engineers use it in places where things must work well all the time. The sensor’s strong build makes it good for hard jobs.

Hilitand Flexible Film Sensor

Overview

Hilitand Flexible Film Sensor is small and good for checking pressure. The sensor uses a nanomaterial base. This makes it bendy and quick to react.

Features and Specs

Hilitand’s sensor can measure up to 10 kg of pressure. The thin and bendy shape makes it easy to put in small spots. The sensor reacts fast to changes in pressure. The nanomaterial base helps it last and work well for a long time.

Pros and Cons

Pros:

- Works well in small gadgets

- Reacts fast to pressure

- Easy to put in tight spots

- Light and easy to use

Cons:

- Can only measure a small amount of pressure

Best Application

Hilitand Flexible Film Sensor is great for wearables, electronics, and health tools. The sensor’s small size and good build make it perfect for tiny devices.

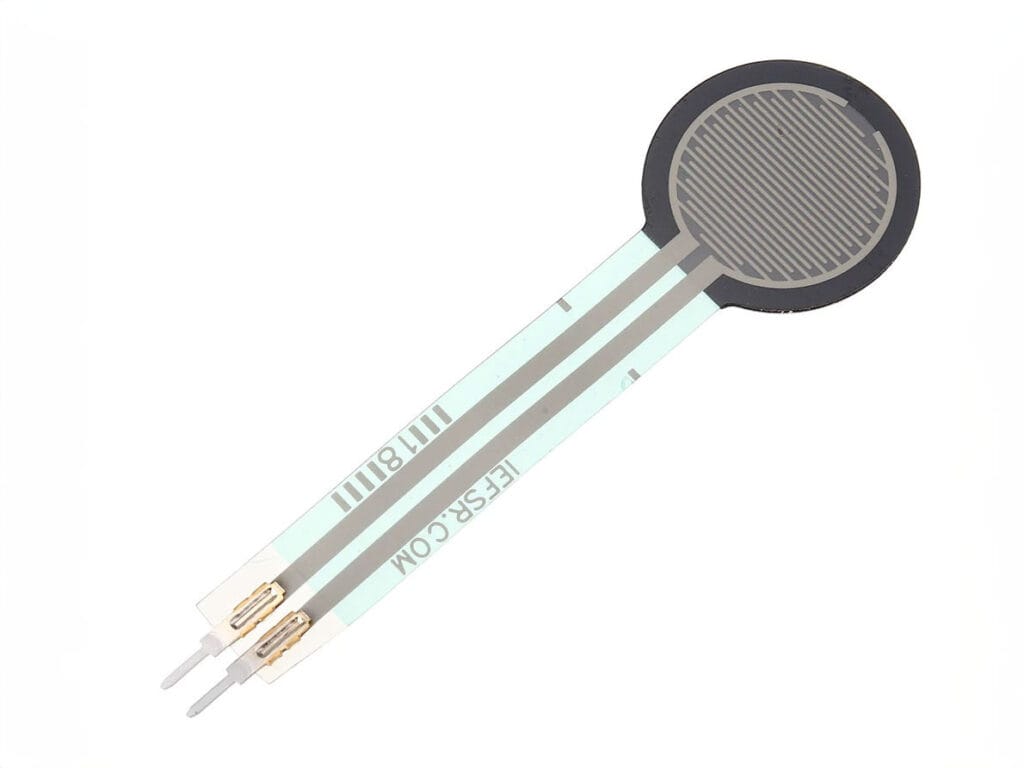

Interlink Electronics FSR 400 Series

Overview

Interlink Electronics FSR 400 Series is easy to use and works in many ways. Many engineers pick these sensors for cars, robots, medical tools, and home gadgets. The sensor is thin and bends, so it fits in small spaces. It reacts fast when you press it. This makes it good for finding touches and checking pressure. The FSR 400 Series lets people add force-sensing to lots of devices.

Features and Specs

The FSR 400 Series is made with a strong polymer thick film. The sensor is about 0.35 mm thick, so it fits in small designs. It can sense force from 0.1 N up to 10 N. When you press it, the resistance changes in a steady way. The sensor can be pressed up to 10 million times and still work. It does not break from shocks or electric problems like EMI or ESD. Engineers often use a simple voltage divider to connect it to microcontrollers.

Pros and Cons

| Aspect | Pros | Cons |

|---|---|---|

| Integration | Easy to use; thin and bendy shape | Needs careful setup and mounting |

| Durability | Lasts long; strong build; handles shocks; safe from EMI/ESD | Might break after a lot of use; can’t be washed; may give wrong signals |

| Sensing Range | Can sense many force levels; steady resistance | More drift than some other sensors |

| Cost | Cheap; easy to find | Not as repeatable or accurate as some special sensors |

| Application Suitability | Good for tough places | Force range and accuracy are limited for some jobs |

The table shows FSR 400 Series is strong, easy to use, and not expensive. But it needs to be set up right and may drift in some uses.

Best Application

Engineers use the FSR 400 Series in many jobs. It works well in car controls, medical tools, and robots. The sensor is reliable for things that need to work a lot and react fast. It also fits in home gadgets where touch or force sensing is needed.

FSRTEK Thin Film Sensor

Overview

FSRTEK Thin Film Sensor is a low-cost way to measure force and pressure. Many engineers like this sensor because it is simple and works well. The thin and bendy shape makes it easy to put in small devices. FSRTEK sensors help add touch or pressure features without costing a lot.

Features and Specs

FSRTEK Thin Film Sensor uses a thin, bendy film that changes resistance when pressed. It can measure up to 10 kg of force. The sensor reacts fast and keeps giving steady results over time. Its design makes it easy to use in home gadgets, game controllers, and small medical tools. FSRTEK sensors work well for most basic jobs.

Pros and Cons

- Pros:

- Low price

- Thin and bendy for easy setup

- Fast reaction to force

- Steady results for most uses

- Cons:

- Not as accurate as fancy sensors

- Only works for small to medium forces

- May need to be checked often in hard jobs

Best Application

FSRTEK Thin Film Sensor is best for home gadgets, games, and simple medical tools. The sensor is reliable and cheap, so it is good for projects with little money. Designers use this sensor when they just need basic force sensing.

Thin Film Coatings and Technology

Material Innovations

Thin film coatings are very important for pressure sensors. Companies use different materials and designs to make sensors work better. SOUSHINE uses special conductive materials in its flexible sensors. These materials help electricity move well inside the sensor. Other brands use coatings like PDMS/CB, PEDOT:PSS, and MXene/graphene. Each material gives the sensor its own special strengths.

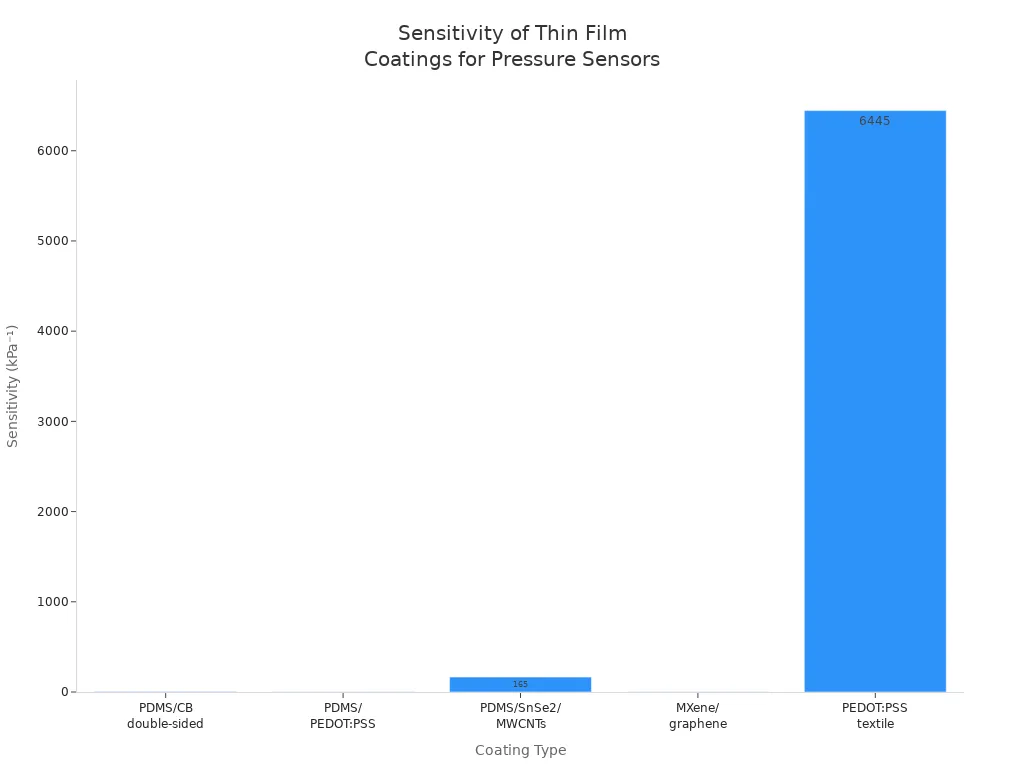

The table below shows how some thin film coatings compare in pressure sensors:

| Material/Coating Type | Microstructure/Structure | Sensitivity (kPa⁻¹) | Sensing Range (kPa) | Durability/Notes |

|---|---|---|---|---|

| PDMS/CB composite film with double-sided microstructures | Sandpaper template | 5.5 | 0–140 | Lasts over 2000 cycles; good mix of sensitivity and range because of contact resistance and conductive paths |

| PDMS/PEDOT:PSS | Sandpaper | 2.32 | 0–100 | Medium sensitivity and range |

| PDMS/SnSe2/MWCNTs | Lotus leaf | 165 | 0–80 | Very sensitive but works in a smaller range |

| MXene/graphene | Film | 2.13 | 0–10 | Not as sensitive and works in a small range |

| PEDOT:PSS | Textile | 6445 | 0–60 | Super sensitive but may not last as long because of the textile base |

Tiny shapes in thin film coatings, like those made with sandpaper, make sensors more sensitive and last longer. These shapes give more places for contact and help electricity move better.

SOUSHINE uses advanced flexible emi shielding films. These films can bend and still let electricity flow well. Other companies might use textile or film coatings, but SOUSHINE’s layers balance sensitivity and how long they last. The coating material and design change how the sensor reacts to pressure.

Durability and Sensitivity

Durability and sensitivity matter a lot for thin film sensors. Special coatings help sensors last longer and keep working well. New studies show that CNT-coated fiber sensors with protective coatings can be used over 5,000 times. These sensors still work after being underwater for 12 hours. Protective coatings also help flexible emi shielding films stand up to tough places.

SOUSHINE’s sensors have special protective coatings that let them bend and not break. These coatings help the sensor stay strong and flexible. Other brands use coatings too, but the material changes how long the sensor lasts. For example, textile coatings can be very sensitive but may wear out faster. Film coatings, like those in flexible emi shielding films, give both flexibility and protection.

Flexible emi shielding films also stop unwanted emi signals. This is important in electronics and other thin film uses. Protective coatings add extra safety, so sensors work better in hard conditions.

SOUSHINE vs. Competing Brands

Innovation

SOUSHINE is a leader in thin film pressure sensors. The company uses special materials and new thin film coatings. These features help the sensors work in many places. SOUSHINE makes sensors for iot devices. This means they fit smart homes, wearables, and factories. The sensors handle emi well, so they avoid signal problems. SOUSHINE also has sensor arrays. These arrays collect more data from different spots. This helps engineers who need flexible tools for new products. Other brands like Setra focus on being very accurate for factories. Hilitand and Interlink are more basic and just offer flexibility. SOUSHINE is different because it mixes flexibility, emi resistance, and iot use in one product.

Reliability

Reliability is very important for pressure sensors. SOUSHINE checks each sensor with strict tests. They do inspections, resistance tests, and first checks before selling. This makes sure every sensor works for customers. SOUSHINE’s sensors keep working after lots of use. They resist emi, so they stay reliable in electronics. Customers say SOUSHINE gives good technical help and helps with setup. The sensors work well in iot systems, where reliability is needed for data and control. Setra is also reliable for factories, but SOUSHINE works well for both home and factory use. Hilitand and Interlink are fine for simple jobs, but not as reliable for hard tasks. FSRTEK is cheap, but may not be as reliable.

SOUSHINE’s focus on reliability helps engineers trust their devices. The sensors keep working even with strong emi. This protects data and keeps devices working right.

Value

SOUSHINE gives value with good performance, support, and custom options. The company helps before and after you buy. You can contact SOUSHINE by email, phone, or in person. They check quality to make sure sensors fit your needs. Many customers like SOUSHINE for quick answers and helpful tips. The sensors are a good mix of price and reliability. This helps companies save money over time. SOUSHINE also gives discounts for big orders, so manufacturers can save more. Other brands like Setra and Interlink have their own value, but SOUSHINE stands out with support and custom options. Hilitand and FSRTEK are cheaper, but may not give the same support or reliability.

| Brand | Innovation | Reliability | Value | Customer Support/Customization |

|---|---|---|---|---|

| SOUSHINE | High (iot, emi, arrays) | High (quality checks, support) | Strong (customization, bulk) | Comprehensive, responsive |

| Setra | Industrial accuracy | High (industrial) | Good (robust, costly) | Standard |

| Hilitand | Compact, flexible | Moderate | Affordable | Limited |

| Interlink | Versatile | Moderate | Good | Standard |

| FSRTEK | Budget-friendly | Basic | Low-cost | Limited |

SOUSHINE’s value comes from reliable products, strong support, and flexible choices for iot and emi projects.

Application Guide for Thin Film Pressure Sensors

Choosing by Application

Picking the right thin film pressure sensor depends on where you use it. Engineers use thin film sensors in iot, medical, cars, factories, and home gadgets. Each area needs something special. Medical devices need to be very exact and always work. Car sensors must handle shaking and hot or cold weather. Home gadgets need sensors that are small and use little power. Factory sensors must survive tough places and block electrical noise.

The table below shows which sensors work best for each job:

| Application Area | Sensor Type | Key Characteristics | Best Suited Products / Uses |

|---|---|---|---|

| Consumer Electronics | Capacitive Thin-Film Sensors | High accuracy, low power consumption | Smartphones, wearables, portable devices |

| Aerospace & Defense | Piezoelectric Thin-Film Sensors | Durable, withstand extreme conditions | Aerospace systems, defense equipment, industrial machinery |

| Industrial (Oil & Gas) | Optical Thin-Film Sensors | High sensitivity, immune to electromagnetic interference | Harsh industrial environments, oil and gas industry |

| Automotive | Various Thin-Film Sensors | Precision, reliability, suitable for EVs and autonomous vehicles | Tire pressure monitoring, engine performance, vehicle systems |

| Medical | Various Thin-Film Sensors | Precision, reliability, critical for healthcare devices | Blood pressure monitors, ventilators, infusion pumps |

Tip: Always pick a sensor that matches what your project needs. For iot, choose sensors that are easy to add and do not use much power.

Budget Considerations

How much money you have matters when picking sensors. Some iot projects need lots of sensors, so costs can go up fast. Engineers should look at both price and how well the sensor works. For simple home gadgets, a cheap sensor like FSRTEK is fine. For medical or factory jobs, paying more for a good sensor saves money later because it will not break as much. Buying in bulk or getting custom sensors can also help save money for big iot projects.

Technical Requirements

What your project needs will help you pick the right sensor. Engineers should check these things:

- What kind of output does the sensor give?

- What type of pressure does it measure?

- Can it handle heat, water, shaking, or electrical noise?

- Will it fit in your device?

- Does it have built-in electronics for better signals?

- How exact and steady does it need to be?

- Can it work with iot systems and microcontrollers?

- Does it meet safety and quality rules?

The table below lists the main technical things to check:

| Technical Requirement | Description |

|---|---|

| Sensor Type | Sealed, vacuum, strain gauge, piezo, thin film, etc. |

| Operating Pressure Range | Safe pressure range for the sensor |

| Operating Temperature Range | Temperature limits for proper operation |

| Output Type | Analog, digital, or wireless signals |

| Accuracy & Drift | Needed precision and stability |

| Resolution | Smallest pressure change detected |

| Supply Voltage | Power needed for the sensor |

| Environmental Conditions | Temperature, humidity, fluids, radiation, physical setup |

| Calibration | Pre-calibrated or user calibration |

| Packaging | Physical protection and size constraints |

| Signal Conditioning | On-board electronics for signal amplification and filtering |

| Connectors | Type and ease of connection for installation and maintenance |

| Certification Standards | Compliance with industry standards |

Note: For iot and smart gadgets, pick sensors that react fast, are easy to add, and can send data wirelessly.

The top five thin film pressure sensors are good for different devices. SOUSHINE is known for new ideas and can bend easily. Setra Systems Model 3100 is very exact and works well in factories. Hilitand is small, so it fits tiny gadgets. Interlink Electronics FSR 400 Series can be used in many ways. FSRTEK is a smart pick if you want to save money. Picking the right sensor depends on many things:

| Factor | Importance for Devices |

|---|---|

| Pressure Range | Makes sure devices stay safe and do not break |

| Temperature Range | Keeps devices working right when it gets hot or cold |

| Material Selection | Helps devices last longer and work better |

| Sensing Element | Changes how well the device senses and how long it works |

| Packaging & Sealing | Stops water and damage from hurting the device |

| Accuracy Requirements | Makes sure the device gives the right numbers |

| Burst Pressure | Stops the device from breaking if pressure gets too high |

| Signal Conditioning | Makes the device’s signals better and easier to use |

Choosing the best sensor helps devices work well and last a long time. Readers should look at the tables and guide to pick the right sensor. For more help, check product links, talk to sellers, or ask for samples to test in your devices.

FAQ

What is a thin film pressure sensor?

A thin film pressure sensor finds force or pressure with a thin, bendy layer. When you press it, the sensor’s resistance changes. Engineers use these sensors in lots of devices to measure pressure well.

How do engineers install thin film pressure sensors?

Engineers stick the sensor onto flat or curved surfaces with glue or clips. They hook up the sensor’s wires to a circuit. Most sensors are small, so they fit in tight spots.

Which industries use thin film pressure sensors?

Lots of industries use these sensors. You can find them in cars, medical tools, electronics, robots, and factory machines. Each industry likes that the sensor is flexible and gives good results.

How long do thin film pressure sensors last?

Most thin film pressure sensors work for thousands of uses. How long they last depends on what they are made of, how you use them, and where they are used. If you put them in right and take care of them, they last longer.

Can thin film pressure sensors measure both light and heavy forces?

Yes, they can. Some sensors feel very soft touches, and others can handle strong pushes. Always look at the sensor’s pressure range before picking one for your project.

Are thin film pressure sensors waterproof?

Some sensors have special coatings or seals to keep water out. Others do not. Always check the IP rating or ask the seller if you need the sensor to work in wet places.

How do engineers choose the right sensor for their project?

Engineers look at things like pressure range, accuracy, size, bendiness, and cost. They also think about where and how the sensor will be used. A table that compares sensors helps them pick fast.