Call us: +86-137-2353-4866

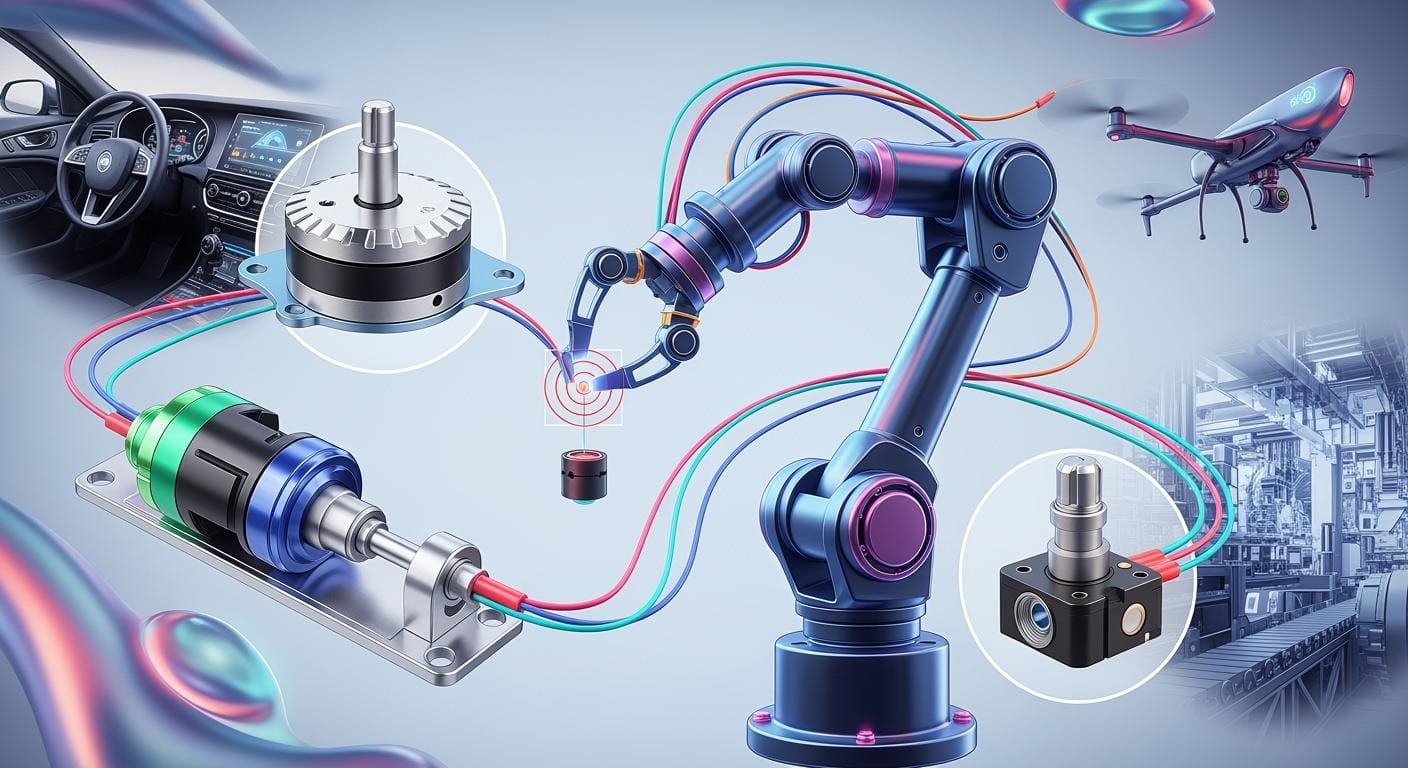

You will see position sensor technologies like potentiometric, magnetic, optical, capacitive, inductive, ultrasonic, Hall effect, MEMS-based, and force sensing resistor changing the future in 2025. These sensors, including advanced force sensing solutions, are driving improvements in smart systems and IoT applications. The market for position sensors is expanding rapidly and is now valued at billions of dollars worldwide. Position sensors and force sensing resistors are found in cars, factories, and smart devices, supporting real-time monitoring and predictive maintenance. Understanding how force sensing and other sensor types operate helps you select the best option for your needs. SOUSHINE offers advanced position sensor and force sensing resistor solutions tailored for every application.

Table of Contents

Key Takeaways

- Position sensors tell you where things are. They also show how things move. These sensors are important in smart devices. You find them in cars and robots too.

- There are many types of position sensors. Some are LVDT, rotary encoders, and Hall effect. Each type works in a special way. Each one has its own good points.

- Position sensors help keep people safe. They also make work faster in places like car factories, hospitals, and other industries.

- SOUSHINE has many kinds of position sensors. These sensors work well and are simple to set up. You can use them in lots of different ways.

- Position sensors help smart systems watch things in real time. They also help control things better. This makes automation and safety better.

- Capacitive and inductive sensors are used a lot. They work well in hard places. They do not need to touch what they measure.

- New position sensors use IoT and AI. This makes them smarter and helps them work better.

- You need to pick the right position sensor for your job. SOUSHINE experts can help you choose the best one.

Overview of Position Sensor Types

What Are Position Sensors?

A position sensor tells you where something is or how far it moved. These sensors help measure how things move, how far they go, or what angle they turn. In 2025, position detection sensors are important in smart devices, cars, and robots. You find them everywhere because they give real-time updates about your surroundings. When you use a position sensor, you can control machines, follow objects, and keep systems safe and smooth.

Some important words to know are sensing range, hysteresis, repeatability, and response time. These words help you see how well a position detection sensor works in different jobs.

Key Types of Position Sensors

There are many kinds of position sensors in today’s technology. Each kind works in its own way and is good for different things. Here are the main types of position detection sensors you might use:

- LVDT Sensors: These check straight-line movement very accurately.

- Rotary Encoders: These find out how much something spins or turns.

- Potentiometers: These measure movement or angle by changing resistance.

- Hall Effect Sensors: These use magnets to find where something is.

- Capacitive and Inductive Sensors: These sense position by checking electrical changes.

- Optical Sensors: These use light to find movement or position.

- Ultrasonic Sensors: These use sound waves to measure distance.

- MEMS-Based Sensors: These tiny sensors fit in small gadgets and track movement.

- Force Sensing Resistors (FSRs): These measure force or pressure to help sense touch or weight.

You use these position sensors in many areas. For example, you see them in aerospace, power plants, cars, factories, medical tools, and robots.

Position Detection Sensors in Modern Industry

Position detection sensors help make jobs automatic and keep people safe. In factories, you use them to move robot arms and check if products are good. In cars, position detection sensors help with things like staying in your lane and avoiding crashes. You also find position detection sensors in airplanes, where they watch moving parts and help pilots. In hospitals, position detection sensors make surgery tools more exact. Gadgets like drones and game controllers use position detection sensors to track movement.

- In factories, position detection sensors help robots work better and make things faster.

- In cars, position detection sensors watch important parts and help keep you safe.

- In airplanes, position detection sensors help keep flights safe by tracking moving parts.

- In hospitals, position detection sensors help doctors use tools more carefully.

- In robots, position detection sensors help robots sense and react to their world.

You need position detection sensors to make smart systems work. These sensors connect to the Internet of Things (IoT) and give you real-time data. They help you control devices from anywhere. As technology gets better, you will see even more ways to use position detection sensors every day.

Potentiometric Position Sensors

Potentiometric Sensor Operation

A potentiometric position sensor checks movement or position by changing resistance. The sensor has a resistive track and a wiper. When the wiper moves, the resistance changes. This change makes a new output voltage. The voltage shows where the wiper is. You can read this voltage to find the wiper’s spot. Potentiometric sensors are simple and do not cost much. You do not need fancy electronics to use them. You can set up these sensors with basic tools.

Tip: Potentiometric sensors are good for easy position checks. You can use them for many jobs without spending a lot.

Potentiometric sensors are cheaper and easier than some other sensors. You can install them fast. You do not need special lessons. Some other sensors use magnets or light. Potentiometric sensors use contact to work, so they are different. The moving parts can wear out after a while. Still, you get a simple answer for many tasks.

Advantages of potentiometric position sensors:

- Low cost

- Simple technology

- Easy to use

Potentiometric Position Sensor Applications

Industrial Automation

You see potentiometric position sensors in many machines at factories. These sensors help check where machine parts are. You can use them in materials testing and gauging systems. They also work in industrial processing equipment. When you need data from moving parts, these sensors give quick feedback. You can control robot arms and conveyor belts with them.

Common uses in industry:

- Finding where machine parts are

- Getting data from moving parts

- Materials testing

- Gauging systems

Automotive Systems

Potentiometric position sensors are used in cars and trucks. These sensors help test new designs and watch moving parts. Car makers use them to measure steering angles and pedal positions. They also check gear shifts. Using these sensors can make cars safer and more comfortable.

- Measuring steering wheel position

- Watching pedal movement

- Checking gear shift positions

SOUSHINE Potentiometric Solutions

SOUSHINE gives potentiometric position sensors for many jobs. You can pick sensors that fit your needs in factories or cars. SOUSHINE sensors work well and are easy to install. You get help from SOUSHINE experts. You can trust SOUSHINE for good position sensor solutions.

Note: SOUSHINE helps you pick the right potentiometric sensor. You can make your system better and more reliable with SOUSHINE products.

Magnetic Position Sensors

Magnetic Sensor Working Principle

Magnetic position sensors help you find where something is. They do this by noticing changes in a magnetic field. Some materials act differently when near magnets. When a sensor is close to a magnet, it reacts to the magnetic field. This helps you measure position very well.

- Magnetic position sensors work by using a sensor and a magnetic field together.

- You see these sensors in factories, robots, and cars. They last a long time and can handle rough places.

- The Magneto-Resistance effect is important. Here, a material’s resistance changes when a magnetic field is around. You see this in metals like iron, nickel, or cobalt.

- Magnetostriction is another idea. Some metals change shape when a magnetic field is near. This helps you measure position very exactly.

Tip: Magnetic sensors do not need to touch what they measure. This makes them last longer and work well in dirty or wet places.

Here is a table that shows the main good and bad points of magnetic position sensors:

| Advantages | Limitations |

|---|---|

| High precision in many uses | Needs careful on-axis alignment |

| Works well in noisy places | Can be affected by uneven magnetic fields |

Magnetic Position Sensor Uses

Robotics and Automation

You find magnetic position sensors in many robots and machines. These sensors help robots know where their arms or tools are. Hall-effect switches are used for limit switch jobs and to check if something is open or closed. These switches are better than old mechanical ones and make machines more reliable. Hall-effect latches help motors turn and sense speed. Robotic vacuums use these sensors to move around your house. In factories, 1D and 3D linear Hall sensors track moving parts and send feedback to control systems. 2D angle position sensors help servo motors work better. They use less power and keep working in hard conditions.

- Hall-effect switches: Used for limit switches and open/close checks

- Hall-effect latches: Help motors turn and sense speed

- 1D and 3D linear Hall sensors: Track position in machines

- 2D angle position sensors: Control motors in servo systems

Medical Devices

You see magnetic position sensors in medical tools. These sensors help doctors and nurses use equipment safely. For example, they track moving parts in surgical robots. They also help watch patient beds and wheelchairs. Magnetic sensors work well in hospitals because they do not wear out fast and can be cleaned often.

SOUSHINE Magnetic Sensor Line

SOUSHINE has many magnetic position sensors for different needs. You can pick sensors for robots, factory machines, or medical tools. SOUSHINE sensors give you accurate results and work well in noisy or rough places. You get help from SOUSHINE experts to choose the right sensor for your job. With SOUSHINE, you can trust your position sensor to work well every time.

Optical Position Sensors

Optical Sensor Functionality

Optical sensors use light to find movement and position. They shine light on a target and watch how it changes. Most optical sensors work as incremental encoders. They turn movement into square-wave signals. You count these signals to see how far something moved. The sensor makes output pulses. The number of pulses shows the change in position. If you use two sensors, you can also tell direction. The order of signals tells if something moves forward or backward. This way, you get both position and direction with high accuracy.

Tip: Optical sensors do not touch what they measure. This helps them last longer and work well in clean or dusty places.

Optical Position Detection Sensors

Consumer Electronics

You see optical sensors in many things you use every day. Your computer mouse uses an optical sensor to track movement. Smartphones use these sensors for touchless controls and face recognition. Game controllers use optical sensors to follow your hand or body. These sensors help make devices more fun and quick to use.

Industrial Robotics

Factories and warehouses use optical sensors for many jobs. Robots use them to weld parts and check product quality. In warehouses, robots use optical sensors to move and manage items. These sensors help robots find the right spot and avoid things. In hospitals, surgical robots use optical tracking to guide tools. Farmers use machines with optical sensors to plant seeds in straight rows and watch their progress.

- Robots weld and check products with high accuracy.

- Warehouse robots move and organize items.

- Surgical robots do careful tasks with steady control.

- Farming machines plant and track rows with precision.

SOUSHINE Optical Sensor Products

SOUSHINE has many optical sensors for different needs. You can pick sensors for electronics, robots, or medical tools. SOUSHINE makes sensors that are accurate and last a long time. You get good results, even in tough places. The company gives you expert advice and technical help. When you choose SOUSHINE, your system gets smarter and works better.

Capacitive Position Sensors

Capacitive Sensor Basics

Capacitive sensors find position by checking changes in capacitance. These sensors use two main ideas: mutual capacitance and self-capacitance.

- Mutual capacitance uses row and column electrodes. When your finger gets close, it changes how the electrodes connect. The sensor checks each row and column to find the spot.

- Self-capacitance measures how much your finger increases the capacitance to the ground. As you move your finger, the sensor notices these changes.

- Most capacitive proximity sensors have two plates that make an open capacitor. One plate gets charged by an oscillator, making an electrostatic field. When something comes near, it changes the field and raises the capacitance. This also changes the oscillator’s frequency. The detector circuit watches this frequency change to find the position.

Capacitive sensors give you fast and accurate position detection. They do not need to touch what they measure, so they last longer and work in many places.

Tip: Capacitive sensors are very sensitive and can notice even small touches or movements.

Capacitive Position Sensor Applications

Touch Interfaces

You find capacitive sensors in many touch screens today. When you use a phone or tablet, you touch a screen that uses this technology. These sensors let you swipe, tap, and use gestures. You get a quick and smooth response. Many home devices like washing machines and coffee makers use capacitive touch panels. You can control these devices easily and keep them clean since you do not press real buttons.

Precision Manufacturing

Capacitive position sensors are important in smart factories. You see them in machines that need careful control and measurement. These sensors help move robot arms, check part positions, and watch assembly lines. In food factories, capacitive sensors help keep things clean by measuring without touching. In cars, you see them in touchscreens and trackpads instead of old switches for a better feel.

Here is a table that shows where you use capacitive sensors and why they are helpful:

| Industry | Application Examples | Advantages |

|---|---|---|

| Consumer Electronics | Washing machines, vacuum cleaners, water purifiers, coffee makers | Flexible, low-cost touch controls, better gesture sensing |

| Automotive | Touchscreen controls, trackpads, replacing mechanical buttons | No-touch sensing, programmable controls, better user experience |

| Aerospace & Defense | Pressure, level, and temperature sensors | Accurate, steady measurements, meets strict rules |

| Healthcare | Medical devices for accurate position sensing | High speed, very fine resolution |

| Food & Beverages | Automated processing and packaging systems | No-touch, clean, accurate |

| Oil & Gas | Monitoring and control for pressure and level | Safe, works well in dangerous places |

SOUSHINE Capacitive Sensor Range

SOUSHINE has many capacitive sensors for your projects. You can pick sensors for touch screens, factory machines, or medical tools. SOUSHINE makes sensors that are accurate and last a long time. You get good results in electronics and smart factories. The company gives you expert help and advice, so you can find the right sensor for your needs.

Note: If you choose SOUSHINE, you get capacitive sensors that make your products special in the market.

Inductive Position Sensors

Inductive Sensor Operation

Inductive position sensors find metal objects by making an electromagnetic field. When metal comes close, the field changes. The sensor notices this and sends a signal. Inductive sensors only work with metals. They give good results even if it is dirty or wet. Dust, oil, or water do not mess up how the sensor works.

Here is a table that shows how inductive sensors compare to other types:

| Sensor Type | Operational Principle | Detection Range | Environmental Sensitivity |

|---|---|---|---|

| Inductive Sensors | Electromagnetic induction, detecting metals | 1mm to 50mm | Tough, not bothered by dust, dirt, oil, or water |

| Capacitive Sensors | Capacitance change, detecting many materials | Several tens of millimeters | Sensitive to wetness, heat, and dust |

| Magnetic Sensors | Changes in magnetic fields | Longer detection distances | Depends on how it is made and used |

Inductive sensors are strong and dependable. They work well in rough places where other sensors might not.

Inductive Position Sensor Applications

Automotive Safety

Inductive sensors are used in many car parts. These sensors help keep you safe by watching how parts move. You find them in:

- Brake pedal sensors

- Accelerator pedal sensors

- Motor position sensors

- Brake system sensors

- Vehicle level sensors

- Transmission range sensors

- Throttle position sensors

- Exhaust gas recirculatory sensors

When you drive, these sensors help your car react fast and right. They help with braking, speeding up, and shifting gears. This makes driving safer and more comfortable.

Factory Automation

Factories use inductive proximity sensors to keep machines working well. These sensors track metal parts and help line things up. You use them for:

- Placing parts in engine building

- Positioning welding robots in car making

- Checking paint thickness in paint shops

- Making sure bolts and gears are good

- Watching part position and speed on conveyors

- Helping robots move exactly during assembly

These sensors work well in tough factory places. They help stop mistakes and keep things moving.

SOUSHINE Inductive Sensor Solutions

SOUSHINE has many inductive sensors for cars and factories. You can pick sensors for your job, like checking brakes or running a factory line. SOUSHINE makes sensors that last and give correct results. You also get help from experts to choose the best sensor.

Tip: If you pick SOUSHINE, you get sensors that help your machines work better and safer.

Ultrasonic Position Sensors

Ultrasonic Sensor Principles

Ultrasonic position sensors use sound waves to check distance. These sensors send out very fast sound pulses. When the sound hits something, it bounces back. The sensor times how long the sound takes to return. This tells you how far away the object is. You do not have to touch the object, so nothing gets dirty or broken.

You can use ultrasonic sensors where other sensors might fail. Dust, smoke, or fog do not block the sound waves. These sensors work with many things, no matter their color or if you can see through them. You get good results even in hard places.

Tip: Ultrasonic sensors do not care if something is shiny, dark, or clear. They can find almost anything in their way.

Main technical advantages of ultrasonic position sensors:

- Find objects no matter their color or if they are see-through

- Work well in dirty, dusty, or foggy places

- Do not touch what they measure, so things stay safe

- Give steady results in many factories

Ultrasonic Position Sensor Uses

Robotics Navigation

Many robots today use ultrasonic sensors. These sensors help robots move and not hit things. When a robot moves, it sends out sound waves. If something is close, the sound comes back fast. The robot knows to stop or turn away. This keeps robots from bumping into things.

Robotic vacuums use ultrasonic sensors to clean your house. They move around chairs and tables without getting stuck. In factories, robots use these sensors to follow walls or paths. The sensors help robots slow down or stop if a person is near. This makes robots safer and smarter.

- Find things in the way and stop crashes

- Guide robots along walls or paths

- Help robots work safely with people

- Keep robot vacuums moving around

Smart Home Devices

Ultrasonic sensors make homes smarter. You see them in doors that open when you walk up. Some lights turn on when they sense you moving. These sensors help smart speakers know when you are in the room. You can use them in alarms to watch for movement, even in the dark or fog.

Ultrasonic sensors work in many home devices because they do not need light. They keep working if it is dusty or wet. You get quick and correct results every time.

- Doors and lights that work by themselves

- Smart speakers that know when you are there

- Alarms that sense movement

- Home robots that do not bump into things

SOUSHINE Ultrasonic Sensor Range

SOUSHINE has many ultrasonic position sensors for your projects. You can pick sensors for robots, smart homes, or factories. SOUSHINE sensors give you good and steady results anywhere. You get help from experts to choose the best sensor. With SOUSHINE, your position sensor projects get smarter and work better.

Note: SOUSHINE ultrasonic sensors help you build safer and smarter systems for any job.

Hall Effect Position Sensors

Hall Effect Sensor Operation

Hall effect sensors measure position without touching things. You run electricity through a conductor. Then you put it in a magnetic field. This makes a voltage across the conductor. You use this voltage to find magnetic fields. Hall effect sensors use this idea to sense movement or position changes. These sensors work well in many places. They do not need direct contact. You get steady and correct readings every time.

Hall effect sensors measure position without touching. This helps them last longer and work well in tough places.

Hall Effect Position Sensor Applications

Electric Vehicles

Hall effect sensors are in many electric vehicle parts. The electric vehicle market is growing fast. In 2022, people bought 10.5 million electric vehicles. Experts think this number will keep going up. More electric vehicles means more sensors are needed.

You find Hall effect sensors in these places:

- Power steering motors

- Chassis positioning

- Dual-clutch transmissions

- Traction motor positioning in hybrid and electric vehicles

- Steering angle detection

These sensors help electric vehicles work safely and smoothly. You get good control over steering and motors. Hall effect sensors also find small changes in magnetic fields. This makes them more accurate.

Industrial Controls

Factories use Hall effect sensors in many machines. These sensors give high accuracy and precision. You can trust them to measure position and movement fast. Here are some reasons to pick Hall effect sensors for industrial controls:

- High accuracy and precision in measuring

- Good response to magnetic field changes

- Can find small changes in magnetic fields

Factories use Hall effect sensors to control motors and track moving parts. They help keep machines safe and working well. You get quick feedback and steady results.

SOUSHINE Hall Effect Sensor Solutions

SOUSHINE has many Hall effect sensors for your projects. You can pick sensors for electric vehicles, factories, or robots. SOUSHINE sensors give steady and correct results. You get help from experts to choose the right sensor. With SOUSHINE, you build smarter systems that last longer and work better.

Tip: If you want a position sensor that does not touch and gives precise results, try SOUSHINE Hall effect sensors for your next project.

MEMS-Based Position Sensors

MEMS Sensor Technology

MEMS means Micro-Electro-Mechanical Systems. These sensors are very tiny. You find them in many new devices. MEMS-based position sensors have small moving parts and electronics on one chip. They can measure movement, tilt, and rotation. MEMS sensors give quick and correct data. They react fast when things change.

New ideas have made MEMS sensors work better.

- AI and machine learning help MEMS sensors process data on the device. This saves energy.

- Energy harvesting lets MEMS sensors use very little power. This helps IoT devices last longer.

- New materials make MEMS sensors more sensitive and dependable.

MEMS sensors became popular when smartphones grew in use.

- The iPhone came out in 2007. This made MEMS sensors common in electronics.

- Smartphones needed navigation and gaming. Companies used more inertial sensors.

- Since 2016, wearables made MEMS sensors even more popular.

MEMS sensors are tiny, smart, and use little power. You can put them in almost any device.

MEMS Position Sensor Applications

Wearable Devices

MEMS sensors are in fitness trackers, smartwatches, and health monitors. They count your steps and check your heart rate. They also watch your sleep. MEMS sensors help wearables stay light and easy to wear. You get instant feedback about your health and activity. The sensors connect to your phone or computer. You can see your progress every day.

Drones and UAVs

MEMS sensors are important in drones and UAVs. You find them in flight controllers and stabilizers. They help drones fly smoothly and avoid things. MEMS sensors make virtual reality training for drone pilots safer. When you use MEMS sensors with AI, drones fly better and react faster.

- MEMS sensors help drones control their flight.

- They help train pilots in virtual reality.

- AI and MEMS together make drones more accurate.

SOUSHINE MEMS Sensor Products

SOUSHINE has many MEMS-based position sensors for your projects. You can pick sensors for wearables, drones, or smart devices. SOUSHINE makes sensors that are small, save energy, and work well. You get help from experts to choose the right sensor. With SOUSHINE, your position sensor projects get smarter and work better.

Tip: If you want to make advanced wearables or drones, use SOUSHINE MEMS sensors for great results.

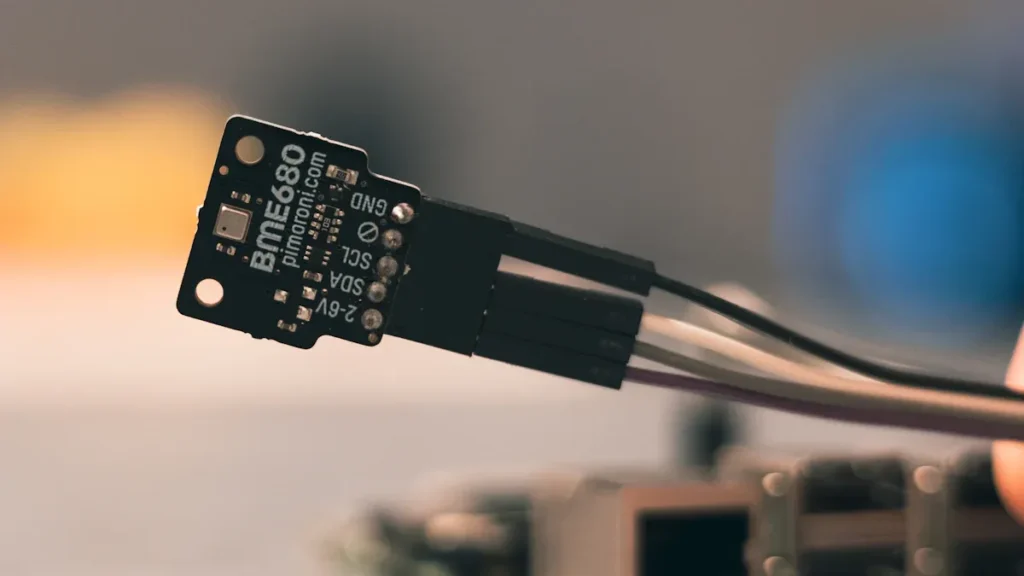

Force Sensing Resistors (FSRs) as Position Detection Sensors

FSR Technology and Operation

You use Force Sensing Resistors when you need sensors that react to touch or pressure. These sensors change resistance when you press on them. The main idea is called piezoresistivity. When you push harder, the resistance goes down. The sensor sends a stronger signal. This helps you measure force and position well.

FSRs have a simple design that works smartly. There are three main parts:

| Component | Description |

|---|---|

| Flexible Substrate | A thin material with two halves of a printed circuit. |

| Spacer | Keeps space between the circuit and the conductive layer. |

| Conductive Substrate | Has a coating that changes when you press on it. |

| Operational Mechanism | When you press, the conductive layer touches the circuit. |

| Measurement Principle | More pressure means more contact, lower resistance, and higher output. |

When you press an FSR, the layers touch and let electricity flow. More force means more contact. The resistance drops and the signal gets stronger. You can set this change to measure force or position exactly. FSRs work as variable resistors. They are great for position sensors in many devices.

FSR Types of Position Sensors in Modern Use

FSR position sensors are used in many industries. They are flexible and reliable, so people use them in modern systems.

Automotive Applications

FSR sensors are found in cars every day. They help with seat detection and driver-assist systems. They also work in touch controls. When you sit down, FSRs sense you and adjust safety features. Touch buttons in dashboards use FSRs to respond fast. These sensors make driving safer and more comfortable.

Healthcare and Medical Devices

FSRs are important in healthcare. You find them in wearable monitors that track health. Smart prosthetics use FSRs to move with you. Surgical tools use FSRs to measure force. This helps doctors do careful work. These sensors give good feedback and help patients.

| Industry | Application Examples |

|---|---|

| Automotive | Seat detection, driver-assist systems, touch controls |

| Healthcare | Wearable monitors, smart prosthetics, surgical tools |

Robotics and Touch Sensing

Robots need sensors to interact with things. FSRs give robots a sense of touch. You see them in robot grippers. They measure how hard the robot holds something. FSRs help robots grip better and avoid breaking things. In automation, FSRs let robots sense position and pressure. This makes robots smarter and safer.

Consumer Electronics Interfaces

FSR sensors are in many electronics you use. You find them in game controllers and touchpads. They are also in smart devices. When you press a button or swipe, FSRs sense your touch and react fast. These sensors make devices easier and more fun to use.

| Type of FSR | Materials/Construction Methods | Performance Impact |

|---|---|---|

| Single Zone FSRs | Two electrodes with special ink on one spot. | Lowers resistance in one area. Simple and cheap. |

| Shunt Mode FSRs | Uses certain electrodes based on force direction. | Senses which way force is applied. |

| Array Sensors | Many single zone FSRs on one base. | Senses force at many spots. Good for keypads or touch screens. |

SOUSHINE FSR Product Line

SOUSHINE makes advanced sensors using FSR technology. You can pick single zone, shunt mode, or array sensors. SOUSHINE FSRs come in many shapes and sizes. You find the right one for your project. They last a long time, even in tough places. They use little power, so they are good for saving energy. SOUSHINE gives expert help and custom solutions. You build smarter systems with reliable sensors.

Tip: If you need sensors that are flexible, strong, and accurate, SOUSHINE FSRs are great for cars, healthcare, robots, and electronics.

Trends in Position Sensor Technology

IoT Integration and Smart Systems

Position detection sensors are changing how you live and work. These sensors now connect to the Internet of Things (IoT). IoT lets many devices talk to each other. Position detection sensors send live data to your phone, computer, or the cloud. You can check on machines, cars, or your home from anywhere. This helps you make smart choices quickly.

Factories use position detection sensors to watch machines and products. You get alerts if something moves out of place. In smart factories, these sensors help robots and machines work together. You save time and make fewer mistakes. Hospitals use position detection sensors to watch patients and equipment. This keeps people safe and helps doctors give better care.

Here are some ways you use position detection sensors in smart systems:

- Home automation: Lights turn on when you walk into a room.

- Smart farming: Sensors track where tractors and tools go.

- Logistics: You can follow packages as they move.

- Healthcare: Doctors check how patients move and stay safe.

Note: Position detection sensors help you stay in control and act fast. You can fix problems before they get worse.

Hybrid and Emerging Position Sensors

New types of position detection sensors come out every year. Hybrid sensors mix two or more technologies. For example, some sensors use both optical and magnetic parts. This makes them more accurate and useful in more places. Some hybrid position detection sensors use touch and force sensing together. You get more details from just one sensor.

Emerging position detection sensors use new materials and designs. MEMS-based sensors keep getting smaller and smarter. You find them in wearables, drones, and even toys. Some new sensors use artificial intelligence to learn from data. They help you spot problems early and make things work better.

Here is a table showing some new trends in position detection sensors:

| Trend | Benefit |

|---|---|

| Hybrid sensor designs | More accuracy and more ways to use them |

| AI-powered sensors | Smarter data and faster choices |

| Flexible and thin sensors | Fit in more shapes and devices |

| Wireless sensor networks | Easier to set up and connect |

You will see position detection sensors in more places as technology grows. You can expect sensors to get faster, smaller, and smarter. These sensors will help you build safer cars, better robots, and smarter homes.

Tip: Keep learning about new position detection sensors. You will find new ways to solve problems and make your projects special.

You can find position sensors in many places, like cars and smart homes. These sensors help you run machines, watch movement, and keep things safe.

- Many industries use them, such as cars, robots, and hospitals. They need sensors for exact and fast information.

- Some new trends are making sensors smaller, adding IoT, and using AI to study data.

| Provider | Strengths | Applications |

|---|---|---|

| SOUSHINE | Very sensitive, strong, and can be changed | Robots, hospitals, cars |

| Interlink | Thin and quick sensors | Wearables, pressure checks |

| Tekscan | Very accurate sensors | Science, sports research |

When you know about each position sensor type, you can pick better. SOUSHINE has smart sensor choices for any job. Keep asking questions and learn about the newest sensor ideas.

FAQ

What is a position sensor?

A position sensor tells you where something is or how far it moved. You use these sensors in machines, cars, and smart gadgets. They help you track movement or location.

How do Force Sensing Resistors (FSRs) work?

FSRs change resistance when you press on them. If you press harder, the resistance goes down. This helps you measure force or touch in many devices.

Where can you use position sensors?

You find position sensors in cars, robots, medical tools, and smart homes. They help control machines, track movement, and keep things safe.

Why should you choose SOUSHINE sensors?

SOUSHINE sensors give accurate results and last a long time. You can pick from many types and get expert help for your project.

What is the difference between capacitive and inductive sensors?

Capacitive sensors sense changes in capacitance and work with many materials. Inductive sensors use electromagnetic fields and only sense metal objects.

Can you use position sensors in harsh environments?

Yes, you can use many position sensors in dusty, wet, or hot places. Inductive and magnetic sensors work well in tough spots.

How do you pick the right position sensor?

Think about what you want to measure and where you will use it. Decide how much accuracy you need. You can ask SOUSHINE experts for advice.

Are position sensors important for IoT?

Yes! Position sensors help smart devices talk to each other. You get real-time data and better control in smart homes, factories, and cars.