Call us: +86-137-2353-4866

The top three tactile sensor types in 2025 are capacitive, piezoelectric, and resistive sensors like the force sensing resistor. You can find these sensors in smartphones, medical devices, and robots. Tactile and touch sensors help make devices work better and keep you safe every day.

SOUSHINE is a leader in force sensing technology. They help industries make things safer, healthier, and more automatic.

| Sensor Type | Market Value (2024) | Growth Factors |

|---|---|---|

| Capacitive | USD 5.3 billion | Accurate, lasts long, more people want multi-touch screens |

| Piezoelectric | USD 4.9 billion | Good signals, new uses, car rules help growth |

| Resistive | USD 8.3 billion (by 2034) | More automation, better control, new tech in factories |

See how new tactile sensors change your world every day.

Table of Contents

Key Takeaways

Tactile sensors help many devices we use every day. You can find them in phones, medical tools, and robots. There are three main tactile sensor types. These are capacitive, piezoelectric, and resistive sensors. Capacitive sensors are very sensitive. People use them in touchscreens and smart devices. Piezoelectric sensors make electric charges when pressed. This makes them good for medical tools and robots. Resistive sensors check force by changing resistance. They are found in gaming controllers and car safety systems. SOUSHINE FSRs are accurate and can be used in many ways. They work well in lots of industries. Picking the best sensor depends on what you need. You should think about sensitivity, size, and power for your project. Tactile sensors keep getting better. They help robots and devices become smarter and safer for us.

Types of Tactile Sensors in 2025

Overview of Tactile and Touch Sensors

You use tactile and touch sensors every day. These sensors help machines feel pressure or touch. You can find them in phones, cars, and robots. Medical tools also use these sensors. Tactile sensor technology keeps getting better. Devices are smarter and safer because of these sensors.

Tactile sensors work in different ways. Some measure resistance changes. Others sense electric charge changes. Some use light to detect touch. Each sensor type is good for certain jobs. You will see how these sensors help you daily.

Key Types of Sensors

Many devices use different sensors. The main types in 2025 are capacitive, piezoelectric, and resistive sensors. Force sensing resistors (FSRs) are a kind of resistive sensor. New sensors like optical and triaxial types are becoming popular too.

Here is a table that shows how each sensor works and where you find it:

| Sensor | Operating Principle | Application |

|---|---|---|

| Resistive | Resistance changes in metal strain gauges result from changes in geometry | Stiffness mapping, hard nodule detection, robotic tissue palpation |

| Capacitive | Two conductive objects with a space between them respond to applied voltage differences | Probe mimicking human fingertip tactile sensing, surgical forceps for tactile feedback |

| Piezoelectric | Applied mechanical stress can generate an electric response | Robotic-based tissue palpation system, portable pen-like devices for oral cancer screening, measuring elasticity of tissue |

| Optical | Acts as a wavelength-selective mirror reflecting light within a narrow spectral width | Fiber Bragg Grating-based force sensors in robotic palpation for haptic perception in surgeries |

Resistive sensors turn force into resistance changes. You use them to measure force or pressure. They also measure movement. Capacitive sensors have two plates. They sense changes when something touches or gets close. These sensors are good for medical devices and touchscreens. Piezoelectric sensors make electric charge when you press them. You find these in robots and health tools. Optical sensors use light changes to measure force or touch. They are very accurate and work well in noisy places. Triaxial sensors measure force in three directions. Robots and prosthetics use them to move better.

You can compare sensors by sensitivity, durability, and cost:

| Sensor Type | Sensitivity | Durability | Cost |

|---|---|---|---|

| Piezoresistive | High frequency response | Poor repeatability, sensitive to temperature | Low cost |

| Capacitive | High sensitivity, low power consumption | Sensitive to noise | Moderate cost |

| Piezoelectric | High sensitivity, stable performance | Extremely robust, can tolerate high temperatures | Moderate cost |

Each sensor type has its own strengths. Capacitive sensors are very sensitive and use little power. Piezoelectric sensors measure quick changes and last a long time. Resistive sensors cost less and measure force well.

Trends in Tactile Sensor Technology

Tactile sensor technology is changing fast in 2025. New sensors use smart materials and designs. Auxetic-structured 3D-printed tactile sensors can stretch and change shape. They stay strong while doing this. Doctors use these sensors to track movement and health. Robots use them to grip things just right.

Some sensors use mechanical metamaterials. These materials get thicker when stretched. This makes sensors more sensitive and stable. You get better wearable devices and smart robots because of these changes. Personalized medicine also improves.

Tip: Pick devices with the right sensor for your needs. The right sensor makes your device safer and easier to use.

You will learn more about each sensor type soon. You will see how capacitive, piezoelectric, and resistive sensors work. You will find out how they help you every day.

Capacitive Tactile Sensor Applications

How Capacitive Sensors Work

You use capacitive tactile pressure sensors every day. These sensors have metal electrodes and a dielectric material. The dielectric can be glass or plastic. They help the sensor feel touch or pressure. When you touch the sensor, your finger changes the electric field. The sensor sees this change in capacitance. It turns the change into data for your device.

| Component | Function |

|---|---|

| Metal Electrodes | Find changes in capacitance when you touch or press. |

| Dielectric Material | Changes how sensitive the sensor is, based on its type and thickness. |

| Capacitance Sensor/Meter | Measures the change and sends the data to your device. |

The oscillator circuit makes an electric field inside the sensor. When you touch the surface, your finger interrupts this field. The sensor quickly notices the change and reacts. This makes capacitive tactile pressure sensors fast and dependable.

Everyday Uses of Capacitive Sensors

Capacitive tactile pressure sensors are in many things you use. They help make your experience easier and more fun.

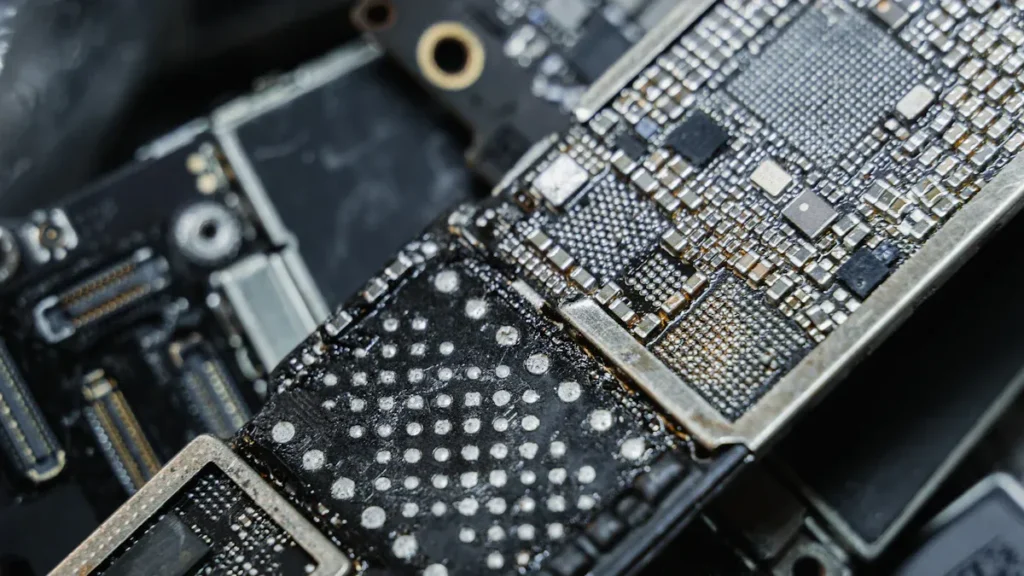

Smartphones and Tablets

You use capacitive sensors when you tap or swipe your phone. These sensors let you zoom, scroll, and play games. They work fast and make your device feel new and simple.

Wearables and Consumer Devices

Smartwatches and fitness trackers use these sensors for touch controls. You can start a workout or check messages with a tap. These sensors also help make devices thinner and look better.

Home Appliances

Many smart home devices use capacitive sensors. You can change lights, set the temperature, or control your TV by touch. These sensors make your home smarter and more comfy.

Tip: Capacitive tactile sensors make devices easier to use. They give you quick responses and fewer touch problems.

Advantages and Drawbacks

Capacitive tactile pressure sensors have many good points. They are very sensitive and react fast. Most modern touchscreens use them for multi-touch and slim looks. These sensors last a long time and do not need much care.

| Advantages | Drawbacks |

|---|---|

| Very sensitive | Can have cross-talk |

| Fast reaction | Needs complex electronics |

| Supports multi-touch | May show hysteresis |

| Modern and slim designs |

You see capacitive tactile sensors in almost half of all electronics. Cars and factories also use these sensors for touch controls. As technology grows, you will find these sensors in more places. They help make your life easier and more fun.

Piezoelectric Tactile Sensor Uses

How Piezoelectric Sensors Operate

Piezoelectric tactile pressure sensors are in many smart devices. These sensors use special materials called PVDF film. When you press or bend them, they make an electric charge. This charge helps measure force in three ways: x, y, and z. The sensor gives quick and correct readings. It often has four PVDF films and a PDMS bump. This design makes the sensor soft and able to bend. You can find these sensors in robots, smart wearables, and medical tools.

| Aspect | Details |

|---|---|

| Sensor Type | Flexible piezoelectric tactile sensor based on PVDF film |

| Measurement Capability | Measures force in x, y, and z directions |

| Sensitivity (z-axis) | (0.436 ± 0.019) V/N |

| Sensitivity (x-axis) | (0.206 ± 0.019) V/N |

| Sensitivity (y-axis) | (0.277 ± 0.019) V/N |

| Key Material | PVDF (Polyvinylidene fluoride) |

| Operating Characteristics | Sensitive to dynamic force, wide frequency range, low power consumption |

| Applications | Robots, wearable devices, plantar force measurement, advanced robotics |

| Piezoelectric Effect | Generates electrical charges when you apply force |

| Structural Design | Four PVDF films and a PDMS bump |

Medical and Industrial Applications

Piezoelectric tactile pressure sensors help in medicine and industry. They are used in tools that need to be fast and exact.

Minimally Invasive Tools

Doctors use these sensors in surgery tools and ultrasound machines. The sensors help guide tools during surgery. This makes surgery safer and helps people heal faster. Tiny sensors also help doctors do surgery with small cuts. Patients feel less pain and get better results.

- Ultrasounds check on babies and help with gentle treatments.

- Pulse sensors stick to skin and watch your heartbeat.

- Stethoscopes use these sensors for better checkups.

- Sleep tests use them to watch muscle moves at night.

- Dental tools use vibrations to clean teeth and treat roots.

Robotic Prosthetics

Robotic prosthetics use these sensors for better control and feeling. The sensors help fake arms and legs feel touch and move. People can move more naturally and hold things better. These sensors help people do daily things more easily. Robots use them to touch and hold things safely.

- Prosthetics and fake skin become more helpful and real.

- Smart tools check how people move and help track health.

Industrial Safety

Piezoelectric tactile pressure sensors are in bubble detectors and pressure mats. These tools check fluids and pressure to keep people safe. Factory robots use these sensors to measure force and stop accidents. This means safer work and better results.

| Application Type | Description |

|---|---|

| Air Bubble Detectors | Detect air bubbles in medical fluids for patient safety |

| Surgical Handpieces | Improve tactile feedback for better surgical outcomes |

| Therapeutic Ultrasound Devices | Use focused ultrasound for therapy |

| Ultrasonic Medical Transducers | Convert ultrasound signals for diagnosis and treatment |

Tip: Piezoelectric tactile pressure sensors give you results you can trust in health and robots.

Pros and Cons

Piezoelectric tactile pressure sensors have many good points. They are very sensitive and save energy. These sensors are small and fit in many devices. You see them in robots, medical tools, and machines. They help measure force and pressure very well.

| Pros | Cons |

|---|---|

| High Sensitivity | Limited Frequency Range |

| Energy Efficiency | Temperature Sensitivity |

| Compact Size | Material Constraints |

| Wide Range of Applications |

You should know these sensors help many robotic sensors work. They let robots do jobs with care and skill. You see them in health care, robots, and safety at work. They help make robots smarter and keep people safe. You get better care and safer jobs because of them.

Resistive Tactile Sensors and FSRs

How Resistive Sensors and FSRs Work

Resistive tactile sensors are in many things that measure force. These sensors use a simple idea to work. When you press the sensor, its resistance changes. This helps you know how much force you use.

Most force sensing resistors, or FSRs, have a bendy base, a spacer, and a layer with special ink. When you push down, the top layer touches the circuit. This lets electricity move through. If you press harder, the resistance gets lower. You can check this change to see the force you use.

Here is what happens:

- If you do not press, resistance is very high, sometimes millions of ohms.

- When you press, the particles get closer. Resistance drops to thousands of ohms.

- You can check the voltage to see the force you use.

Makers use things like special ink, bendy plastic, and coated sheets. These help the sensor bend and not break. The sensor is tough and can feel small touches.

SOUSHINE Force Sensing Resistors

SOUSHINE is a top company for FSRs. Their sensors are very accurate and react fast. SOUSHINE uses smart designs and strong materials. This gives you sensors you can trust in many places.

Here is a table to compare SOUSHINE and others:

| Feature | SOUSHINE’s Technology | Competitors |

|---|---|---|

| Accuracy | High | Lower |

| Durability | Long-lasting | Varies |

| Customization | Many choices | Fewer choices |

| Power Consumption | Low | Higher |

| Integration Ease | Simple | Harder |

You get lots of good things with SOUSHINE FSRs:

- Very accurate force readings

- Uses little power, so it saves energy

- You can pick the size, shape, and how sensitive it is

- Reacts very fast, less than 0.015 milliseconds

- Works in hot or cold, from -40°C to +85°C

- Can feel light touches, from 10 grams to 1000 grams

SOUSHINE lets you choose the sensor’s size, shape, and color. You can also pick the material, thickness, and sticky part. This helps you fit the sensor in almost any device. You can use SOUSHINE FSRs in robots, health tools, smart watches, and more.

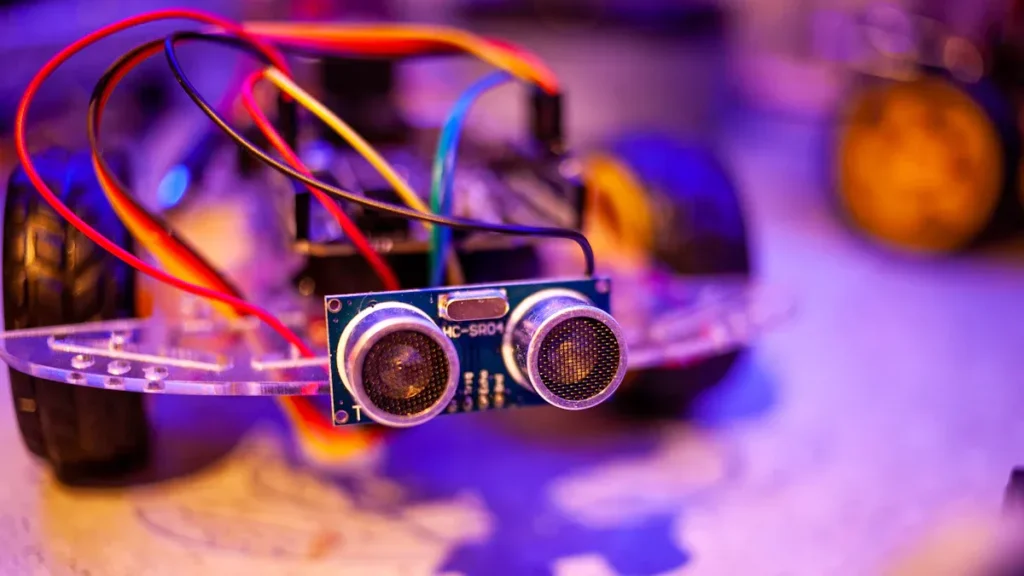

Grasp-Force Measurement in Robotics

Resistive tactile sensors help robots hold things safely. These sensors give robots a sense of touch. Robots use this to change how hard they grip. This is called grasp-force measurement.

When a robot picks up something, the sensor tells it the force. If the robot squeezes too hard, the sensor tells it to loosen. If it is too soft, the sensor says to squeeze more. This helps robots hold things of many shapes and weights.

Robots can measure both up-and-down and side-to-side forces. This lets robots pick up soft fruit without squishing it. They can also hold tools without dropping them. You see this in robot hands, fake arms, and robots that help doctors.

Robots need this control to work with people and fragile things. Grasp-force measurement makes robots smarter and safer. You can trust these sensors to help robots do careful work in many places.

Everyday Uses of Resistive Sensors

Resistive tactile sensors and force sensing resistors (FSRs) are in many things you use. These sensors help you use technology in your daily life. They make things easier, safer, and more fun. Let’s see how you use them in different areas.

Robotics and Automation

Robots work in places like factories, warehouses, and hospitals. They use resistive sensors to check how hard they grip things. If a robot picks up something soft, the sensor tells it to squeeze gently. If it picks up something heavy, the sensor tells it to grip tighter. This helps robots hold fruit or tools without breaking them. Sensors also help robots stay safe around people. If a robot touches something it should not, the sensor tells it to stop or move away. These sensors give robots a sense of touch. Robots can do careful jobs because of this.

Gaming Controllers

When you play video games, you want your controller to work well. Many controllers have resistive sensors inside. These sensors check how hard you press buttons or triggers. If you press lightly, your game character moves slowly. If you press harder, your character moves faster. This helps you control your game better. You feel more connected to the game. The sensors make your gaming more fun and exciting.

Healthcare Devices

Resistive sensors are important in healthcare. Hospitals use them to watch patients in beds. The sensors can tell if a patient moves or gets up. This helps nurses keep patients safe. You also find these sensors in shoes and insoles. They measure pressure on your feet. Doctors use this to help with foot problems. Medical devices use resistive sensors to check fluid levels or find leaks. This keeps patients safe and helps doctors do their jobs better.

Here are some ways resistive sensors help in healthcare:

- Bed sensors watch if a patient moves.

- Fluid sensors check levels in medical devices.

- Podiatry sensors measure pressure in shoes and insoles.

Automotive and Industrial

Cars and factories use resistive sensors for safety and better work. In cars, these sensors know if someone is sitting in a seat. The car can turn on airbags or alarms if needed. Braking systems use these sensors to measure pressure. This helps you stop your car safely. Factories use resistive sensors to watch machines and track supplies. For example, sensors on shelves can tell when items are low. Workers can restock before things run out.

Robots are in many factories too. They use sensors to handle parts and check if products are good. Sensors help robots do careful jobs, like putting together electronics or packing breakable things.

Note: Resistive tactile sensors and FSRs help make your world safer and smarter. You use them every day, even if you do not notice.

Comparison of Tactile Sensor Types

Sensor Features Table

You can look at the main features of each tactile sensor. This table helps you pick the best sensor for your needs.

| Feature | Capacitive Sensors | Piezoelectric Sensors | Resistive Sensors (FSRs) |

|---|---|---|---|

| Sensitivity | High | Very High | Moderate to High |

| Response Speed | Fast | Very Fast | Fast |

| Durability | Good | Excellent | Excellent |

| Power Consumption | Low | Very Low | Low |

| Cost | Moderate | Moderate | Low |

| Best Use | Touchscreens, medical | Medical, industrial, robots | Robots, gaming, automotive |

| Output Signal | Analog/Digital | Analog | Analog |

| Size Options | Small to medium | Small | Very flexible |

Tip: Use this table to help you choose a sensor. Picking the right features gives you better results.

Choosing the Right Tactile Sensor

Think about a few things before you pick a sensor. Every project needs something different. Here are the main things to look at:

| Factor | Description |

|---|---|

| Technology Types | Some sensors work better for certain jobs. For example, resistive sensors are good for robots and games. |

| Environmental Factors | Hot, cold, or wet places can change how sensors work. |

| Performance Characteristics | Check accuracy, repeatability, and speed. These are important for robots and medical tools. |

Also, remember these points:

- Signal Form: Choose if you want analog or digital output.

- Size & Mounting: Small spaces need small sensors.

- Energy & Voltage: Make sure your sensor matches your power supply.

- Capacitive sensors are best for medical devices that need high accuracy, like pressure monitors.

- Resistive sensors are not good for very low-pressure jobs, like headsets that measure below 1 psi.

Note: Always match the sensor to your robot’s job. The right sensor keeps robots safe and working well.

Application Scenarios

Robots use different sensors for different jobs. Each sensor type fits a special task.

- In robotics, capacitive sensors help robots feel light touches on screens or in medical tools.

- Piezoelectric sensors help robots measure quick force changes. Robots use these in factories and hospitals.

- Resistive sensors help robots grip things, play games, and keep cars safe.

Here are some examples:

| Tactile Sensor Type | Application Scenario | Description |

|---|---|---|

| Capacitive | Medical Devices | Measures pressure for patient safety and device control |

| Piezoelectric | Industrial Robots | Detects fast force changes for safe and precise movement |

| Resistive (FSRs) | Robotic Grippers | Measures grip force to hold items gently or firmly |

| Resistive (FSRs) | Gaming Controllers | Reads how hard you press buttons for better game control |

| Resistive (FSRs) | Automotive Safety | Detects seat occupancy and pressure for airbags and brakes |

You see sensors in robots everywhere. Robots use sensors to pick up fruit, build electronics, and help doctors. Robots in warehouses use sensors to sort packages and stop drops. Robots in factories use sensors to check if parts fit right. Robots in hospitals use sensors to help with surgery and patient care. Robots in homes use sensors to make life easier and safer.

Robots need the right sensors to do their jobs. You see robots making your world smarter every day.

Future of Tactile and Touch Sensors

Multi-Perception and Triaxial Sensors

Big changes are coming for tactile and touch sensors. Multi-perception and triaxial sensors help robots feel better. These sensors let robots sense force from three directions. Robots can pick up and move things with more skill.

- Triaxial sensors are now used in human-machine interfaces.

- New e-skin technology helps robots sense like real skin.

- Some systems use tactile sensors to keep data safe, like in cryptography.

- Adaptive pressure feedback lets robots change their grip right away.

Triaxial sensors have cool features:

- They sense tiny details, smaller than your fingertip can feel.

- They stay strong after over 50,000 uses.

- They measure force very well, even with light touches.

Robotic sensors help robots grab odd-shaped or slippery things. These sensors give feedback about how a robot’s hand touches objects. Robots can do harder jobs, like sorting fruit or building electronics, without dropping or breaking things.

Robots with triaxial sensors can work in places people cannot go. This makes jobs safer and faster.

Innovations in Robotic Prosthetics

New robotic prosthetics use advanced tactile sensors. These devices help people feel pressure and texture again. For example, the LUKE Arm lets users sense grip strength and surface feel. This makes daily life easier and more natural.

Here is how sensors in robotics help prosthetics:

| Application | Description |

|---|---|

| Grip force control | Small sensors help users hold fragile items safely. |

| Gait analysis and optimization | Sensors track walking patterns for smoother movement. |

| Enhancing balance and stability | Sensors help users stay steady on rough ground. |

| Tactile feedback | Users feel texture, shape, and weight, making tasks easier. |

| Customized prosthetic design | Sensors check if a new prosthetic fits and works well. |

| Predictive maintenance | Sensors watch for problems, so repairs happen before breakdowns. |

Prosthetic hands now have many grip patterns. Some hands move faster or slower based on how hard you press. Fingers can wrap around objects of different shapes. These features help users pick up coins, hold cups, or shake hands easily.

- Tactile feedback gives a real sense of touch.

- Many grip patterns help users hold different things.

- Speed control makes movements smooth.

- Conforming grasp lets fingers fit around any object.

Evolving Everyday Applications

You will see tactile and touch sensors in more places each year. Robots use these sensors in hospitals, farms, and homes. In surgery, tactile sensors help doctors work safely and with more care. In farming, robots use sensors to pick fruit gently.

| Application Area | Description |

|---|---|

| Minimally Invasive Surgery (MIS) | Sensors help doctors use tiny tools for safer surgery. |

| Robotics | Robots use sensors to handle things in messy or changing places. |

| Agriculture | Robots pick fruit and check crops with gentle touch. |

| Humanoid Robots | Robots with sensors can work with people and learn from them. |

| Haptic Displays | Sensors turn touch into digital feelings for games and learning. |

| Legged Robots | Robots walk on rough ground using sensors in their feet. |

Robots are now in factories, hospitals, and homes. Robots use tactile sensors to fold laundry, help patients, or pack groceries. Smart fabrics and wearables use sensors for fitness and health tracking. Consumer electronics use tactile sensors for better touch screens and controls.

The market for tactile sensors grows as AI, IoT, and new materials get better. Robots become smarter and safer with improved sensors.

You may face some problems, like sensors not working well in hot or wet places. Regular checks and care keep sensors working right. New ideas like quantum sensing will make sensors even more exact. You will see robots and devices that can sense, learn, and help you in new ways.

You can find three main tactile sensor types around you: capacitive, piezoelectric, and resistive. These sensors help robots work with people and things. SOUSHINE FSRs are special because they fit many needs and give quick data. They also help keep things safe. Robots use tactile sensors in games, cars, hospitals, and more. Learning about these sensors helps you make better choices. Robots will get smarter and safer. This will change how you live and work.

| Feature | SOUSHINE Sensor | Typical Alternatives |

|---|---|---|

| Custom Fit | Yes | Limited |

| Real-Time Data | Yes | Sometimes |

| Weight Detection | Yes | Not always |

| Child Detection | Yes | Rare |

- Robots can hold things and feel pressure in many jobs.

- Robots work in hospitals, factories, and homes.

- Robots help make life safer and more comfortable.

FAQ

What is a tactile sensor?

A tactile sensor lets a device feel touch or pressure. You see these sensors in robots, phones, and medical tools. They help machines know when you touch them or when something is close.

How do force sensing resistors (FSRs) work?

FSRs change their resistance when you press on them. If you press harder, the resistance goes down. Devices use this change to tell how much force you use.

Where do you see tactile sensors in daily life?

You use tactile sensors in phones, game controllers, cars, and smart home gadgets. Hospitals put them in beds and medical tools. Robots use them to hold and move things safely.

Why are SOUSHINE FSRs special?

SOUSHINE FSRs give very accurate force readings. They last a long time and use little energy. You can choose the size and shape you want. These sensors work well in many places, even tough ones.

Can tactile sensors help robots work safely?

Yes! Tactile sensors let robots feel how hard they grip things. Robots use this to hold objects gently or tightly. This keeps people and things safe.

What is the difference between capacitive and resistive sensors?

Capacitive sensors use electric fields to sense touch. Resistive sensors use pressure to change resistance. Capacitive sensors are good for touchscreens. Resistive sensors are better for measuring force or pressure.

Are tactile sensors expensive?

Most tactile sensors, like FSRs, cost less than other types. You can find cheap options for many uses. Some advanced sensors cost more, but they have better features.

How do I choose the right tactile sensor?

Think about what you need the sensor to do. Check how sensitive it is, its size, and how much power it uses. Pick one that fits your device and job. You can ask experts or read guides for help.