Call us: +86-137-2353-4866

A force transducer checks how much force is put on something. People use force every day, like when they press a button or step on a scale. Factories need force transducers to keep machines safe and working well. SOUSHINE is a leader in force sensing technology. They make sensors for many different businesses. The force sensor market is getting bigger. It is now worth billions of dollars all over the world.

| Benefit | Description |

|---|---|

| Improved Precision | Accurate force helps factories make better things. |

| Increased Safety | Sensors help stop accidents by watching force levels. |

| Enhanced Efficiency | Good force control makes things work better. |

| Greater Adaptability | Systems can change for different force and loads. |

Think about a car seat that knows when someone sits down. A force sensing resistor finds the force and helps keep people safe.

Table of Contents

Key Takeaways

- Force transducers check how much force is on something. They change this force into an electrical signal.

- Strain gauge load cells are used to measure force very well. Many industries use them, like car makers and hospitals.

- Piezoelectric sensors are good for measuring fast force changes. They help in things like wind tunnel tests.

- Capacitive force sensors are very sensitive. You can find them in touchscreens and health monitors.

- Force sensing resistors (FSRs) are simple and not expensive. They work in many devices, like cars and electronics people use.

- Picking the right force transducer depends on the kind of load, where it will be used, and how exact it needs to be.

- You need to calibrate and install force sensors the right way. This helps them measure correctly and last longer.

- SOUSHINE has many force sensors. They help people choose the best sensor for what they need.

How Force Transducers Work

Principle

Force transducers help people know how much force is used. They change a push or pull into an electrical signal. When something presses on the sensor, it bends a tiny bit. The sensor can feel this small bend. The sensor uses this change to make a signal people can read.

- Load cells use strain gauges to make force into electrical signals.

- Strain gauges feel when they stretch or squeeze from force, which changes their resistance.

- A Wheatstone bridge checks these resistance changes and makes a signal that shows the force.

This way, people can measure even very small forces with good accuracy.

Components

Most force transducers have a few main parts. Each part helps the sensor give the right measurement. Here is a simple table that shows the main parts and what they do:

| Component | Function |

|---|---|

| Strain Gauge | Measures how much the sensor stretches or squeezes when force is used. |

| Electrical Signal | Changes the resistance into a signal people can read and use. |

| Signal Processing | Reads the signal and helps give a clear and correct force measurement. |

These parts work together so the sensor can notice even small changes in force.

Signal Conversion

When a force transducer feels a change, it makes an analog signal. This signal is very small, sometimes just a few millivolts. To use this signal, the sensor needs to make it bigger or change it to another type. Signal conditioning helps with this job. It can turn the analog signal into a digital one or into a format like 4-20 mA. The Wheatstone bridge setup helps the sensor notice even tiny changes in resistance. This setup makes sure the sensor gives correct readings, even when the force is weak. Good signal conversion means people can trust the numbers they get from the sensor.

Force Transducer Types

Strain Gauge

Overview

A strain gauge force transducer uses a thin metal foil. The foil changes resistance when it stretches or squeezes. This sensor sticks to a surface that feels force. When the surface bends, the strain gauge moves too. The shape change causes a small resistance change. The sensor reads this and makes a signal. People use strain gauge load cells for many measurements. These sensors measure small and large forces very well. The Wheatstone bridge circuit helps with temperature changes. It also gives steady readings.

Strain gauge load cells work for tension and compression. They measure force for a long time and stay accurate.

Here is a quick look at how strain gauge force transducers compare to other types:

| Type of Force Transducer | Working Principle | Applications |

|---|---|---|

| Strain Gauges | Resistance changes when a metal foil bends from force. | Used in many force measurement jobs, like factories and hospitals. |

| Load Cells | Turns force from weight into an electrical signal. | Smart scales and force measuring tools. |

| Force Sensing Resistors | Resistance changes when a special material bends. | Used in electronic scales, robots, medical tools, and controls. |

Applications

Strain gauge load cells are used in many places. Civil engineers use them for bridges and dams. Doctors use them in surgery robots and dialysis machines. Aerospace engineers use them for aircraft parts. Cars use them for seatbelt tension and airbags. Factories use them for process control and testing. Robots use them to grip things with the right force. Touchscreens use them for precise input. Washing machines use them for load measurement. Industrial automation uses them for force checks in machines.

- Civil engineering: bridge and dam safety

- Medical devices: surgical robots, infusion pumps

- Aerospace: aircraft load measurement

- Automotive: seatbelt and airbag systems

- Manufacturing: process control, quality testing

- Robotics: robot grippers and arms

- Consumer electronics: touchscreens

- Home appliances: washing machines, dishwashers

- Industrial automation: assembly and material handling

Piezoelectric

Overview

Piezoelectric force transducers use special materials like quartz. When you press these materials, they make an electric charge. The sensor collects this charge and makes a signal. The voltage matches the force used. Piezoelectric sensors react fast and measure quick forces. They do not need much movement to work. These sensors use quartz crystals, PZT ceramics, and other crystals.

Piezoelectric sensors measure both steady and changing forces. They work best when the force changes quickly.

Applications

Piezoelectric force sensors work where speed is important. Wind tunnels use them to measure air forces. Machines use them for real-time force checks. Big machines use them for multi-direction force measurement. These sensors help with high-speed force and impact tests. Their high sensitivity makes them good for big force measurement.

- Wind tunnel testing: aerodynamic force measurement

- Mechanical systems: real-time force monitoring

- Transmission shaft systems: multi-dimensional load measurement

- Impact testing: high-speed force measurement

- Robotics: dynamic force sensing

Capacitive

Overview

A capacitive force transducer has two plates with a gap. When you press the sensor, the plates move closer or farther. This changes the capacitance, which the sensor reads. Capacitive sensors are very sensitive to small force changes. They have high noise immunity and high input impedance. This means they do not affect the circuit much. These sensors need outside power to work.

| Feature | Capacitive Transducer | Other Types (e.g., Strain Gauges) |

|---|---|---|

| Sensitivity | Very sensitive | Less sensitive |

| Noise Immunity | High | Lower |

| Input Impedance | High | Often lower |

| Frequency Response | Good for dynamic studies | Less effective |

| External Power Required | Yes | Not always |

Applications

Capacitive force sensors are in many new devices. Phones and tablets use them for pressure touchscreens. Health monitors use them to track pulse and breathing. Precision tools use them for accurate force checks. These sensors help users and give real-time health data.

- Pressure-sensitive touchscreens: smartphones, tablets

- Wearable health monitors: pulse and respiration tracking

- Precision instrumentation: accurate force measurement

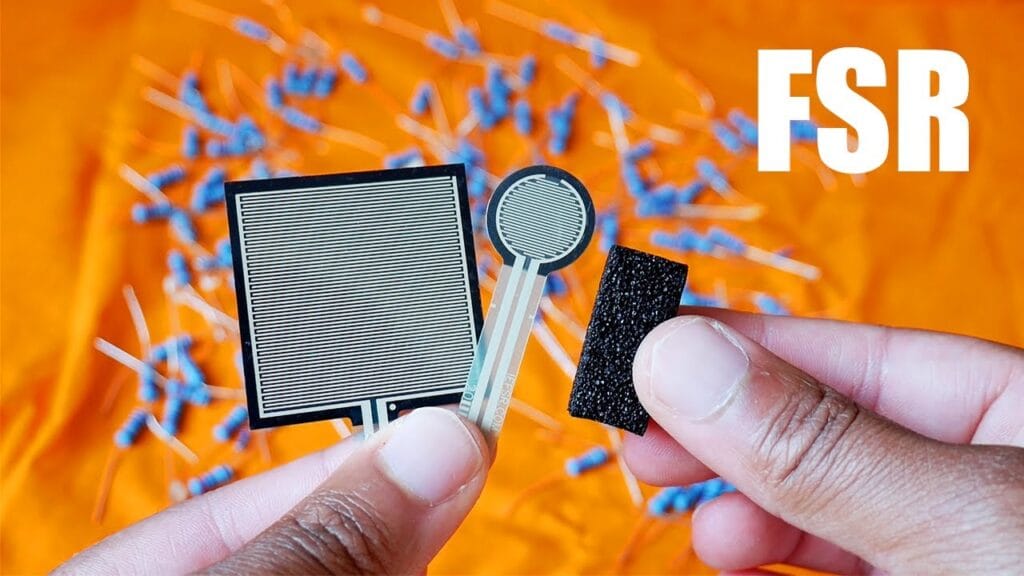

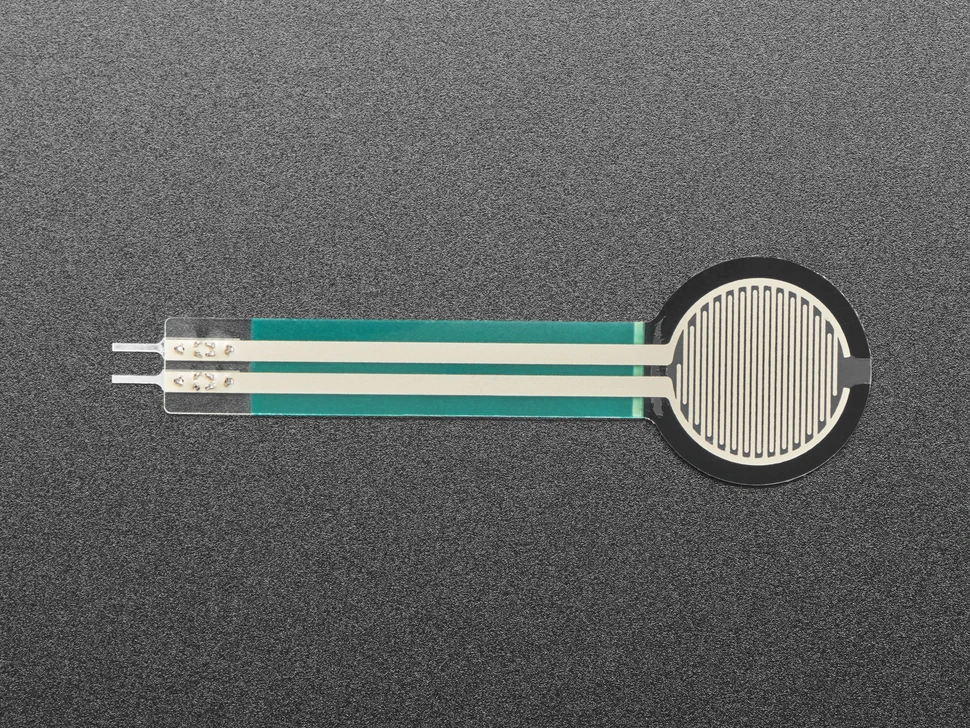

Force Sensing Resistors

Overview

Force sensing resistors, called FSRs, are special sensors. They are thin and bend easily. People like them because they are simple to use. When you press on an FSR, its resistance changes. Pushing harder makes the resistance go down. SOUSHINE makes FSRs for many different jobs. These sensors have a bendy base, a spacer, and a layer that carries electricity. When you push on the sensor, the layers touch. This makes the sensor send out a signal.

FSRs have some cool features:

- They do not cost much.

- You can add them to new or old products.

- They are thin and can fit in small spaces.

- You can get them in many shapes and sizes.

- They can handle bumps and shocks.

- They use very little power.

SOUSHINE’s FSRs last a long time and work in hard places. These sensors help people check force and pressure very well.

Applications

SOUSHINE FSRs are used in lots of jobs. Cars use them to know if someone is sitting down. Hospitals use them to watch how patients move and help with rehab. Robots use FSRs to feel things and hold them right. Phones and tablets use them for touch buttons. Factories use FSRs to check machines and keep workers safe. Planes and defense systems use them in tough places.

Here is a table that shows where SOUSHINE FSRs are used:

| Industry Application | Description |

|---|---|

| Automotive | Makes cars smarter, safer, and more reliable. |

| Healthcare & Medical | Helps measure and watch patients, keeping them safe. |

| Robotics | Gives robots a sense of touch so they can learn and change. |

| Consumer Electronics | Makes devices more fun and easy to use. |

| Industrial | Helps factories work better and waste less. |

| Aerospace & Defense | Works well in hard and changing places. |

SOUSHINE FSRs connect to control systems like PLCs and microcontrollers. They measure force very well and can handle many different forces. Their design works for many uses and stays strong outside or in factories.

Load-Cell

Overview

A load-cell is an important part of many force sensors. It checks force by turning it into an electrical signal. Most load cells use strain gauges. When you put weight on the cell, the strain gauge bends. This bending changes its resistance. The circuit reads this and shows the weight.

Load cells are simple but strong. They have a metal body with strain gauges on it. When the metal bends, the strain gauges change resistance. The circuit fixes errors to make the reading better. This helps the load cell stay accurate for a long time.

Here are some main things about load cells:

- Strain gauges bend when force is used.

- The circuit fixes mistakes to make readings better.

- Load cells turn force into an electrical signal.

- They have a part that bends when loaded.

- The resistance change shows the weight.

- Strain gauge load cells are used a lot in factories.

- The metal bends and changes the strain gauge resistance.

- This design gives good weight readings.

- Load cells are good for watching loads for a long time.

- They are used for important weight jobs.

Applications

Load cells are used in many fields. Factories use them to weigh things and control machines. Cars and planes use them to test parts and check force. Hospitals use load cells for patient lifts and rehab tools. Big machines and building equipment need load cells for safety and working well. Science labs use load cells to test materials and new things.

Here is a table that shows the usual load ranges for load cells in different jobs:

| Industry | Load Range (lbs) |

|---|---|

| Aerospace | 0 to 30,000 |

| Automotive | 0 to 30,000 |

| Materials Testing | 0 to 30,000 |

| Industrial Automation | 0 to 30,000 |

| Energy Sector | 0 to 30,000 |

| Heavy Machinery and Construction | 0 to 50,000 to 400,000 |

| Biomechanics and Medical Devices | 0 to 50,000 |

| Custom Machinery and Equipment | 0 to 50,000 to 400,000 |

Load cells need to handle different weights. Some jobs need to check small weights. Others need to handle very big weights. It is important for load cells to be accurate for safety and quality. Strain gauge load cells help by giving steady and correct numbers. Load cell measurement is important in many areas, like making cars or building bridges.

Force Sensors Applications

Automotive

Cars use force sensors to help keep people safe. Engineers put these sensors in cars for crash tests. The sensors measure force on car parts and people. This helps make cars safer. Force sensors are also used when you drive every day.

- Seat belt sensors check how tight the seat belt is. This helps protect people in a crash.

- Seat occupancy sensors know if someone is sitting down. The car uses this to decide if the airbag should go off.

- Braking systems use force sensors to see how hard you press the brake. This helps the car stop better.

- Tire pressure systems use force sensors to check each tire. This keeps the car safe and steady.

Engineers also use force sensors to see how far car parts move in a crash. They watch how the wheels and suspension react. Crash dummy sensors measure force on the body to check safety rules. SOUSHINE FSRs work well because they are thin and bendy. They can fit many car shapes. Their load-cell design gives good force readings for big and small loads.

Healthcare

Force sensors help doctors and nurses take care of patients. Hospitals use them in beds to see if a patient moves or needs help. In therapy, force sensors track how much force a patient uses. This helps doctors see if the patient is getting better.

A small force sensor can watch a patient’s recovery. It makes therapy more fun by giving feedback right away.

Prosthetics and exoskeletons use force sensors to feel what the user does. This makes moving feel more real. Surgical robots use force sensors for better control in surgery. Patient monitors use force sensors to check for bed sores and grip strength. SOUSHINE FSRs are good here because they can be made in many shapes and sizes. Their load-cell design gives strong and steady readings, even after many uses.

Robotics

Robots need force sensors to work with things around them. These sensors help robots hold things with the right force. Strain gauge sensors check pulling and pushing in robot arms. Piezoelectric sensors react fast to force changes. Capacitive sensors can feel light touches without touching. Six-axis force/torque sensors give robots full control for hard jobs.

Force sensors let robots do careful work like putting small parts together. They help robots know if something is wrong or if they touch a person. This keeps people and robots safe. SOUSHINE FSRs give robots a sense of touch. Their load-cell design lets robots measure force well in many jobs. Engineers can pick the right size and shape for each robot. This makes SOUSHINE sensors good for many robot tasks.

Consumer Electronics

People use force sensors in things like phones and game controllers. These sensors help devices know how hard you press. This makes using the device easier and more fun. A light touch can open an app. Pressing harder can show more choices. This helps people do more with less work.

Force sensors in screens help stop mistakes. The device only works when you really touch it. This means fewer wrong taps and better control. Game controllers use force sensors for more ways to play. A soft press might make a character walk. Pressing harder could make them run. This makes games feel more real.

SOUSHINE’s force sensing resistors fit well in these devices. They are thin and bend easily, so they fit in small spaces. Companies can pick the shape and size they need. This makes SOUSHINE sensors a good choice for many electronics.

Industrial Automation

Factories use force sensors to keep machines working well. These sensors check the force in pressing, cutting, or moving parts. If the force is wrong, the sensor sends a signal. This helps workers fix problems fast.

Force sensors help with quality checks and process control. They make sure each product is made the same way. Load cells are important for these jobs. They measure the weight on machines and tools. This keeps work safe and steady.

Here is a table that shows why force sensors are important in factories:

| Benefit | Description |

|---|---|

| Precision | Force sensors give steady and correct measurements, helping keep product quality high. |

| Reliability | They work all the time, so machines do not stop often. |

| Integration | Their small size lets them fit into many systems. |

- Sensors help factories work faster.

- They keep workers safe by checking force levels.

- Good data from sensors helps make better choices and more products.

SOUSHINE has load-cell and force-sensor options for many factory jobs. Their products can handle different weights and fit many machines. Companies can ask for special designs to match their needs.

Aerospace

The aerospace field needs very careful force measurement. Planes and spacecraft feel strong forces when they fly. Engineers use force sensors to check the load on landing gear. This keeps weight balanced and safe for takeoff and landing.

Force sensors also help control the plane. They measure the force on parts like ailerons and rudders. This helps pilots steer the plane better. Load cells check the force on wings and other parts. This helps find problems before they get worse.

- Landing gear sensors check load during takeoff and landing.

- Flight control sensors measure force on moving parts.

- Structural health sensors test airframes for stress and damage.

SOUSHINE’s force-sensor and load-cell products work well in tough places. Their sensors give steady readings and can be made for special needs. This helps keep planes and spacecraft safe and working right.

Choosing a Force Transducer

Key Factors

Picking the right force sensors starts with knowing what matters most. Each sensor works best when matched to the right job. Here are some things to think about:

- Load characteristics: Look at the type of load. Is it bending, compression, tension, or shear? Each load-cell handles force in a different way.

- Environmental factors: Check where the sensor will go. Some places have moisture, dust, or big temperature changes. The sensor must work well in these spots.

- Load cell location: Make sure the load-cell fits in the space. Some machines have tight spots, so the size and shape matter.

- Measurement range: The sensor should handle the full range of force needed. Too small, and it might break. Too big, and it might not give good accuracy.

- Accuracy: Some jobs need high-precision force measurement. Others just need a rough idea. Pick a sensor that matches the accuracy needed.

- Durability: Some force sensors face shocks or heavy use. The load-cell must last in these cases.

A good choice means the sensor will give steady measurement and last longer.

Application Match

Every application needs a different kind of force-sensor. Matching the right sensor to the job helps get the best results. Here are some tips:

- Precision: Some force sensors give high-precision readings. Others work for general force measurement.

- Static or dynamic: Some jobs need to measure force that stays the same. Others need to track changing force. Pick a load-cell that fits the job.

- External factors: Temperature and setup can change how a sensor works. Some load-cells handle heat or cold better than others.

- Disturbance: Try to avoid things like side loads or off-center force. These can change the measurement and make it less accurate.

- Temperature behavior: Strain gauge load-cells have special features for temperature. They keep the measurement steady, even when it gets hot or cold.

A good match means the force-sensor will give the right measurement every time.

SOUSHINE Guide

SOUSHINE helps people pick the best force sensors for any job. Their team knows how to match each load-cell to the right application. They offer:

| Service | What SOUSHINE Provides |

|---|---|

| Technical Support | Help with picking and setting up force sensors |

| Customization | Load-cells in many shapes and sizes |

| Quality Assurance | Careful checks for steady measurement |

| Design Consultation | Advice for special force-sensor needs |

SOUSHINE’s force sensors work in many places, from cars to robots. Their load-cells handle many types of load and force. The team helps with every step, from picking the sensor to making sure it works right. People can trust SOUSHINE for high-precision force measurement and strong support.

Tip: Talk to SOUSHINE’s experts early. They can help find the best load-cell for any force-sensor job.

Maintenance and Best Practices

Installation

Proper installation helps force sensors and load cells give accurate results. People should follow a few simple steps to keep each sensor working well:

- Never pull or carry a sensor by its cable. This can damage the sensor and affect force readings.

- Keep the cable secure. Loose cables can change the signal from the load cell.

- Do not bend the strain relief. For moving parts, keep bends gentle—at least ten times the cable’s diameter. For a one-time bend, use two to three times the diameter.

- Plug in the sensor during installation. Watch the output to see if the zero reading changes.

- Place the sensor in a dry, clean spot. Only use it in wet or dirty places if the sensor’s IP rating allows.

- Know the load range. Never put more force on the load cell than it can handle.

These steps help each load cell and force sensor last longer and work better.

Calibration

Load cell calibration keeps force sensors accurate over time. People use different methods to check and adjust each load cell. Here is a table that shows common ways to calibrate:

| Calibration Method | Description |

|---|---|

| Deadweight Machines | Used for compression or tension calibrations from 44.5 N to 4.448 222 MN. |

| Calibration Report | Shows the link between applied force and measured deformation. |

| System Calibration | Can use the customer’s device or special lab equipment. |

When doing load cell calibration, people check for:

- Zero offset

- Linearity

- Hysteresis

- Repeatability

- Temperature shift span and zero

Most experts suggest recalibrating each load cell once a year. In tough places or for important jobs, people may need to do load cell calibration more often. Regular sensor calibration helps keep force sensors and load cells working right.

Troubleshooting

Sometimes, force sensors or load cells do not work as expected. People can follow these steps to find and fix problems:

- Check the power supply. Make sure it matches the sensor’s needs.

- Inspect all connections and wiring. Look for loose or damaged wires.

- Use a multimeter to test the output signal while the sensor works.

- Review calibration settings. Make sure the load cell calibration matches the maker’s guide.

- Check the environment. Make sure it fits the sensor’s limits for moisture and temperature.

- Look for any mechanical damage to the load cell.

- Keep the sensor away from strong electromagnetic fields.

- Confirm the load matches the sensor’s range.

- Ask a technician for help if the problem stays.

- Watch for signal changes over time.

- Make sure the sensor has proper grounding.

- Write down each troubleshooting step.

- Do regular maintenance on every load cell and force sensor.

Moisture, heat, and vibration can hurt force sensors. Damaged wires or bad power can also cause problems. Regular checks and quick fixes help each load cell and force sensor stay reliable.

Knowing about force transducer types helps people measure better. It also helps machines work smoothly. Picking the right sensor makes jobs safer. It also makes things more reliable. Strain gauge sensors do not change much over time. Piezoelectric sensors are good for fast changes. The sensor you pick changes how exact the data is.

- SOUSHINE helps people use their sensors.

- Each sensor has a one-year warranty.

- Guides and training help people in medical jobs and more.

People can find out more by looking at SOUSHINE’s guides and products.

FAQ

What is a force transducer?

A force transducer checks push or pull on things. It turns this force into an electrical signal. People use these devices in many jobs to keep things safe and working well.

How do force sensing resistors (FSRs) work?

FSRs change resistance when you press on them. Pressing harder makes the resistance go down. Devices read this change and show how much force is used.

Where can people find force sensors in daily life?

People see force sensors in car seats, game controllers, touchscreens, and medical beds. These sensors help devices know when you touch or press them.

Why do engineers choose SOUSHINE FSRs?

Engineers pick SOUSHINE FSRs because they fit many shapes and sizes. They last a long time and use little power. SOUSHINE also helps with design and setup.

How often should someone calibrate a force sensor?

Most experts say to check and calibrate force sensors once a year. In busy places, people may need to check them more often.

Can force sensors handle rough environments?

Many force sensors, like SOUSHINE FSRs, work well in tough places. They can handle bumps, shocks, and changes in temperature.

What should someone do if a force sensor gives odd readings?

First, check the power and wires. Make sure the sensor is in the right spot. If problems stay, ask a technician or contact support.

Are force sensors safe for use in medical devices?

Yes, many force sensors meet safety rules for medical tools. They help doctors and nurses watch patients and control equipment.