Call us: +86-137-2353-4866

Touch sensors find out when something touches them and make something happen. They are often used to tell if something is touched or not in devices. Tactile pressure sensors check how much force or pressure is used. They give more details about the touch and where it happens. These sensors are very important in electronics, healthcare, and robots. The table below shows how tactile sensors work in different uses.

| Type of Sensor | Description |

|---|---|

| Tactile Sensor | Robots use these for things like not bumping into stuff and picking things up. |

| Pressure Sensor Array | Made of tactels that feel normal forces. They give a clear picture of where things touch. |

| Types of Tactile Sensors | These include piezoresistive, piezoelectric, optical, capacitive, and elastoresistive sensors. |

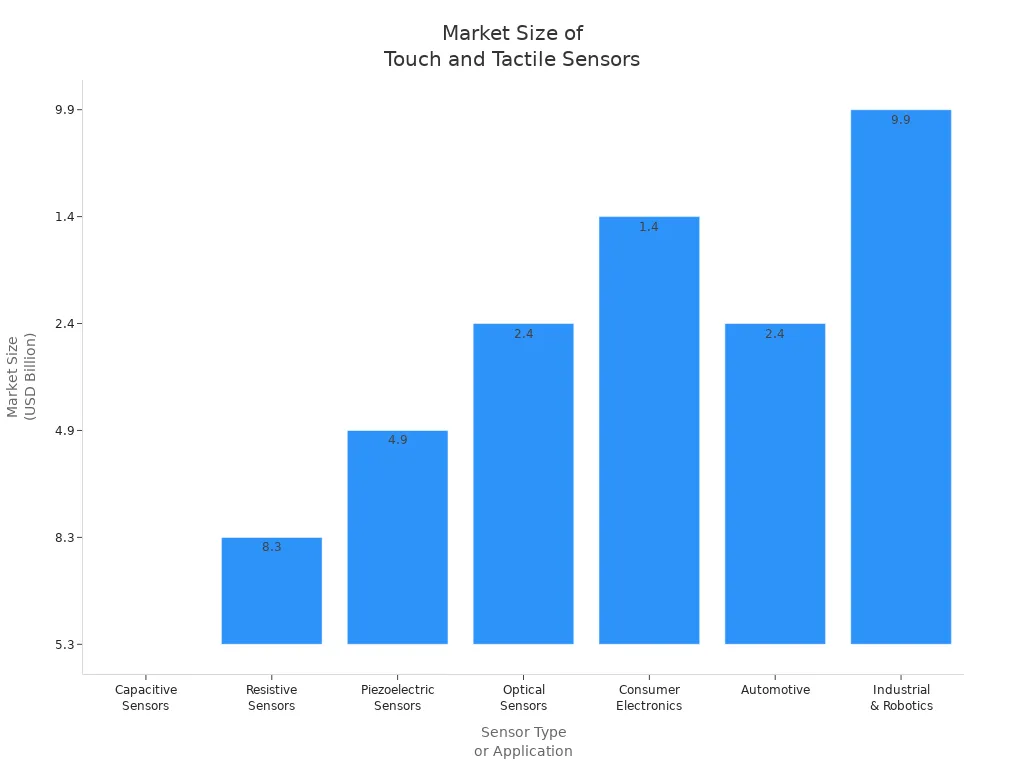

Devices use force sensing to make things safer and more correct. A force sensing resistor helps measure touch and pressure in many new systems. The chart below shows the market size of main sensor types.

Table of Contents

Key Takeaways

- Touch sensors can tell when they are touched. They work like switches and start actions.

- Tactile pressure sensors give more details about a touch. They show how hard and where the touch happens.

- Capacitive sensors react to soft touches. Resistive sensors need a harder press to work.

- Tactile sensors are very important in robots, healthcare, and smart devices. They help make things safer and easier to control.

- Pressure mapping shows spots with high pressure. This helps stop injuries, especially in healthcare.

- Picking the best sensor depends on what you need it for. It also depends on how sensitive it should be.

- SOUSHINE sensors give live data and special features for many industries. They help make things safer and work better.

- More people want tactile sensors now. Technology is getting better, so the market is growing in many areas.

Touch Sensors Overview

Touch sensors let devices know when something touches them. They work like switches. When you touch them, they send a signal. This signal starts an action. Most touch sensors check if you touch a certain spot. For example, a finger on a screen. This makes them good for simple on-off jobs.

Touch Sensor Principles

Touch sensors use different ways to sense touch. The two main types are capacitive and resistive.

Capacitive

A capacitive sensor checks for changes in capacitance. It has two plates with a gap between them. When a finger gets close, the capacitance changes. The sensor notices this and sends a signal. Capacitive sensors work with light touches. They also let you swipe or pinch. Many phones and tablets use capacitive sensors.

Resistive

A resistive sensor senses pressure. It has several layers. When you press down, the top layer touches the bottom one. This closes a circuit and sends a signal. Resistive sensors need a hard press to work. They are used in tough places, like factories.

Tip: Capacitive sensors are good for gentle touches. Resistive sensors are better for rough use.

Key Features

Touch sensors have features that help in many places. The table below shows how capacitive and resistive sensors compare:

| Feature | Capacitive Touch Sensors | Resistive Touch Sensors |

|---|---|---|

| Detection Method | Measures changes in capacitance | Detects pressure on the surface |

| Interaction Type | Supports multi-touch and gestures | Captures single-point touch |

| User Experience | Responds to light touches | Needs a firm press |

| Applications | Phones, tablets, touch screens | Industrial panels, ATMs |

| Robustness | Sensitive, less durable in harsh areas | Durable, works in tough conditions |

Touch sensors are in many devices. People use them in phones, tablets, and laptops for easy control. Factories use them in machines to help workers. Hospitals use them in monitors and lights to keep things clean. Cars use them in screens to help drivers. Smart homes use them for lights and security.

- Touch sensors sense touch and work like switches.

- Capacitive sensors check for changes in capacitance.

- Resistive sensors work when you press hard.

These sensors make devices simple to use. They help people use technology every day.

Tactile Sensor Fundamentals

Tactile sensors help machines feel and measure touch. They can tell if something touches them. They also know how hard and where the touch happens. Touch sensors usually give a simple yes or no. Tactile sensors give more details about the touch. This helps robots, medical tools, and smart surfaces work better.

Tactile Pressure Sensor Types

There are different kinds of tactile pressure sensors. Each kind senses force in its own way. The main types are:

Piezoresistive

Piezoresistive tactile sensors check for changes in resistance. When you press on them, the resistance changes. They are good at sensing normal force. These sensors are cheap and react fast.

Capacitive

Capacitive tactile sensors sense changes in capacitance. They have two plates that move closer or farther apart. When you press, the sensor notices the change. These sensors are very sensitive and can feel soft touches. Robots and medical tools often use them.

Optical

Optical tactile sensors use light to sense pressure. When you press, the light pattern changes. The sensor measures these changes. Some sensors use cameras to make detailed pressure maps.

Other Technologies

Other tactile sensors include piezoelectric, triboelectric, and strain-gauge types. Piezoelectric sensors sense quick changes in pressure. Triboelectric sensors use new ways to sense touch. Strain-gauge sensors measure how much something bends. Some sensors mix two or more ways to work better.

Note: Some tactile sensors can sense more than one thing. Dual-parameter sensors can measure both pressure and temperature. Integrated bimodal sensors have two sensors in one spot. Each one senses something different.

| Type of Sensor | Description |

|---|---|

| Dual-parameter sensor | One sensor that senses pressure and temperature and gives two signals. |

| Integrated bimodal sensor | Two sensors in one spot, each sensing a different thing. |

Tactile Sensor Characteristics

Tactile sensors can show where and how hard something presses. They use grids of small points to make pressure maps. These maps help robots hold things safely. Doctors use them to watch patient health.

Tactile sensors use different ways to work. Resistive sensors check for resistance changes. Capacitive sensors sense changes between plates. Optical sensors use light to see changes. Piezoelectric sensors sense quick pressure.

Some new tactile sensors are thin-film arrays, biomimetic sensors, and e-skin. Thin-film arrays are thin and bendy. They cover big areas and give clear pressure data. Biomimetic sensors act like real skin. E-skin uses soft materials to sense pressure, heat, and pain.

| Sensor Type | Characteristics |

|---|---|

| Piezoresistive | Good at sensing normal force |

| Piezoelectric | Very sensitive, cheap, senses quick pressure, reacts fast |

| Capacitive | Very sensitive, can do many things |

| Triboelectric | New technology with special ways to sense |

| Sensor Type | Unique Characteristics |

|---|---|

| Multifunctional | Very sensitive, wide range, fast, works the same each time |

| Fingerprint-inspired | Uses new materials, gives feedback and reacts in real time |

Tactile sensors are important in robots, prosthetics, and smart devices. They help machines work safely and carefully.

Tip: Tactile sensors give more details than touch sensors. They help devices know not just if something is touched, but also how and where.

| Sensor Type | Description |

|---|---|

| Touch Sensor | Senses touch at one spot, usually just yes or no. |

| Tactile Sensor | Measures force over an area, giving more details about touch. |

- Tactile sensors use resistive, capacitive, optical, and piezoelectric ways.

- Tactile array sensors make clear pressure maps.

- New tactile sensors include thin-film, biomimetic, and e-skin types.

Tactile Sensing in Practice

Pressure Mapping

Pressure mapping uses tactile sensors to show how force spreads out. Engineers use these systems to get data for making and testing products. This technology helps find spots with too much pressure. High pressure can cause pain or even hurt someone if not fixed. In health care, pressure sensors in beds and chairs help stop sores. They do this by watching pressure points over time. SOUSHINE makes products like mattress sensors and smart seat sensors. These use pressure measurement to help with health and comfort.

- Pressure mapping gives clear feedback to change products.

- It helps designers make things safer and more comfy.

- Watching pressure over time helps people in hospitals and care homes.

Force Detection

Force detection uses tactile sensors to measure how much force is used. These sensors are important in robots and prosthetic limbs. Robots use pressure sensors to change their grip. This helps them not drop or crush things. Prosthetic limbs use force detection to help people move and react to changes. Capacitive pressure sensors are very sensitive to light touches. Piezoresistive sensors react fast. The table below shows how sensitive and accurate these sensors are:

| Sensor Type | Sensitivity (kPa) | Accuracy Level |

|---|---|---|

| Capacitive | 0.024 (< 10 kPa) | Very sensitive, but stray capacitance can be a problem |

| Piezoresistive | Varies | Has problems with hysteresis and being the same each time |

Force detection helps robots handle things safely in surgery. It also makes prosthetics work better. SOUSHINE’s robot sensor and flexible pressure sensor help robots and devices do tasks with more control.

Multi-Modal Sensing

Multi-modal sensing mixes different data, like pressure, temperature, and sight. Tactile sensors with these features help robots know what things are, where they are, and grab them well. This technology helps with hard jobs in real life, like cleaning and working with people. E-skin uses lots of sensors to act like real skin. These systems help people use devices more easily, especially if they have disabilities.

SOUSHINE’s array sensor gets data from many places at once. It gives real-time feedback on pressure, movement, and temperature. This helps with advanced tactile sensing in robots, health care, and smart devices.

Note: Tactile sensors are very important in robots, prosthetics, and devices for people with disabilities. They help measure pressure, find force, and watch many things at once for better safety and use.

| Application Area | Description |

|---|---|

| Robotics | Helps robots move better and change how they grab things. It lets them feel contact and force right away. |

| Prosthetics | Makes fake limbs react faster and more exactly. It helps them change to new things around them. |

| Accessibility Devices | Uses e-skin to make sensors that feel like real skin for better use. |

| Robotic Surgery | Gives exact feedback so doctors can move things safely during surgery. |

| Human-Robot Collaboration | Helps people and robots work together better by giving more sensory feedback. |

Key Differences

Function

Touch sensors find out when something touches a surface. They work like switches and send a signal when touched. Tactile sensors do more than just sense touch. They measure how hard and where the touch happens. Pressure sensors in this group can tell how much force is used and where it is. Tactile sensors help machines learn more about touch. They are used for jobs that need more than just on or off. For example, robots use tactile sensors to pick things up without dropping them. In prosthetics, tactile sensors help people control fake limbs. Pressure sensors in tactile systems also help track how much force a patient puts on a bed or chair.

Tactile sensors give more details than touch sensors. They can measure force, where the touch is, and sometimes temperature.

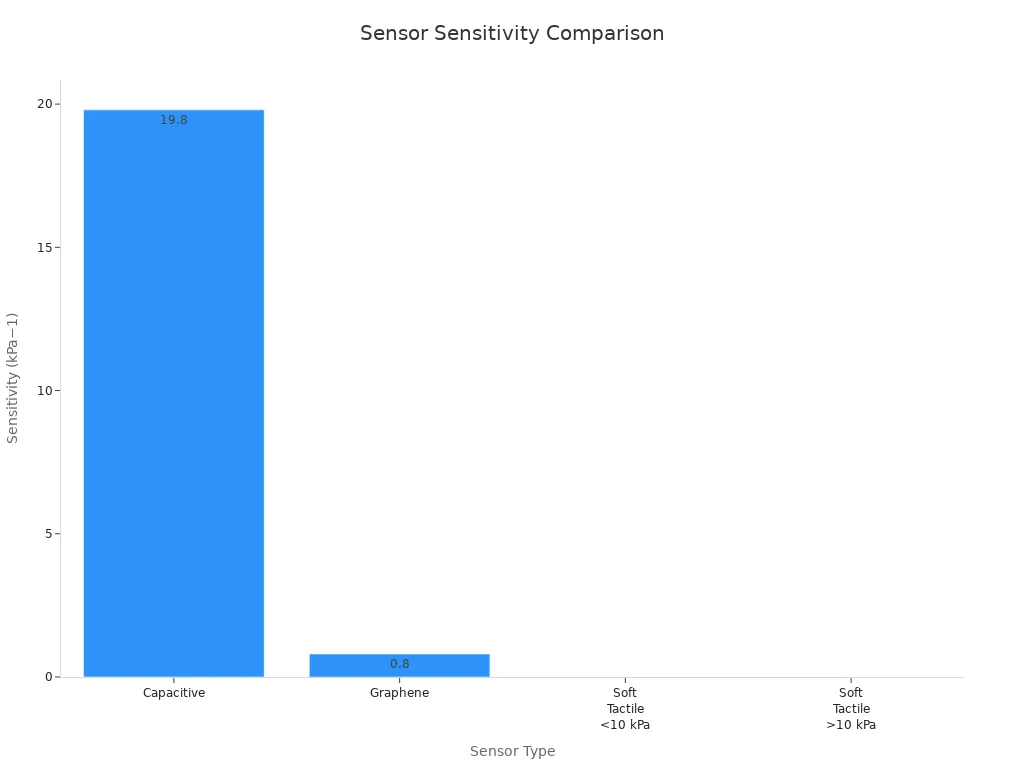

Sensitivity

Sensitivity means how well a sensor can notice small changes. Touch sensors react to a simple touch or press. They do not show how hard someone presses. Tactile sensors, including pressure sensors, can sense many levels of force. Some can feel very light touches, while others sense strong pushes. The table below shows how sensitive different sensors are and what they can measure:

| Sensor Type | Sensitivity (kPa) | Measurement Range (N) | Response Time (ms) |

|---|---|---|---|

| Capacitive | 19.8 | 0–2 | <40 |

| Graphene | 0.8 | 2–40 | <20 |

| Soft Tactile | 0.00348 (<10 kPa) | 0–2 and 2–40 | <40 |

Some special tactile sensors can sense up to 40.12 kPa−1 and measure up to 1000 kPa. This high sensitivity is good for jobs that need careful pressure checks.

Tactile sensors often work very fast. Many can react in less than 40 milliseconds. This helps with real-time checks in robots, health, and safety. Pressure sensors in tactile arrays can show where and how much force is on a surface.

Use Cases

Tactile sensors and pressure sensors are used in many fields. The choice depends on how much detail is needed. Touch sensors are good for simple controls. Tactile sensors are better for jobs that need more feedback about force and place.

| Industry | Application Examples |

|---|---|

| Automotives | Checking pressure in brakes and tires for safety. |

| Electronics | Used in touchscreens and handheld devices. |

| Paper Manufacturing | Used for quality checks during making paper. |

| Packaging | Making sure food and medicine packages are sealed right. |

| Ergonomics | Measuring pressure in things like golf clubs, bike seats, and beds. |

| Nursing Care | Used to watch and check on patients. |

- Medical: Tactile sensors help in surgery and patient checks.

- Automotive: Pressure sensors in brakes and tires make cars safer.

- Robotics: Tactile sensors help robots handle things and work with people.

- Consumer Products: Touch sensors are in many handheld gadgets.

Tactile sensors are important for health checks. They watch pressure points for patients in hospitals and care homes. Pressure sensors in comfort products help designers make things safer and more comfy. In robots, tactile sensors help machines hold things and stop accidents. In packaging and factories, tactile sensors help keep products good and the same every time.

Tactile sensors and pressure sensors help with many kinds of checks. They make things safer, more comfortable, and work better in many areas.

Sensor Applications

Consumer Devices

Lots of everyday devices use touch sensors and tactile sensors. These sensors help make devices easier to use. Phones, tablets, and smartwatches use touch sensors for simple actions. Tactile sensors let devices feel pressure and different gestures. Wearables use pressure sensors to check heart rate and movement. Smart homes use tactile sensors for lights and security panels. SOUSHINE’s Force Sensing Resistor helps designers make devices that react to different pressures. This makes controls work better and more correctly.

The market for these sensors is getting bigger every year. The table below shows how many consumer devices use touch sensors and tactile pressure sensors:

| Sensor Type | Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|---|

| Touch Sensors | 2024 | 1.25 | 15.2 |

| Touch Sensors | 2033 | 4.45 | |

| Tactile Pressure Sensors | 2024 | 15.33 | 11.10 |

| Tactile Pressure Sensors | 2031 | 35.59 |

Industrial Uses

Factories use tactile sensors and pressure sensors for many jobs. These sensors help watch spray patterns and control robot hands. They also check if products are made right. Tactile sensors can find liquids and solids during spray tests. Robotic grippers use capacitive sensors to control force and find objects. Pressure sensors give simple signals to keep machines safe.

- Tactile sensors check spray accuracy in factories.

- Robot hands use capacitive sensors to control force.

- Process control uses tactile sensors to handle heavy loads.

- AI-powered tactile sensors help find tiny problems in microchips.

- Assembly lines use tactile sensors to fit parts together right.

SOUSHINE’s Force Sensing Resistor gives good pressure checks and quick answers. This sensor helps keep factories safe and products strong.

Robotics and Medical

Robots and medical tools need tactile sensors and pressure sensors for hard jobs. In robots, tactile sensors help hands hold soft things and do careful work. Pressure sensors help robots change grip strength and not break things. Medical tools use tactile sensors to watch force during surgery and patient care. Prosthetics use tactile sensors to help people move and feel changes in pressure.

| Type of Sensor | Working Principle | Applications |

|---|---|---|

| Piezoresistive Sensors | Resistance changes with pressure | Detecting force and pressure in surgical tools |

| Capacitive Sensors | Capacitance changes with force | Monitoring contact with tissues and organs |

| Optical Sensors | Light changes with pressure | Providing detailed surface texture feedback |

Tactile sensors help doctors do surgery better by giving quick feedback. This lets doctors control tools well and lowers risks. Robots use tactile sensors to watch grip and movement, making them safer. SOUSHINE’s Force Sensing Resistor helps robots and medical tools by giving fast and correct pressure checks.

Note: Tactile sensors and pressure sensors are very important for safety and control in many jobs. They are used in lots of new technology because they can do many things.

Choosing a Sensor

Application Needs

Picking the right sensor means knowing what the device must do. Some sensors are good for simple touch. Others can measure pressure or force. In hospitals, resistive tactile sensors help study how people walk. They also help with body movement tests. Capacitive tactile sensors are very accurate and give the same results each time. This is important for devices that need FDA approval. If you need steady and correct pressure readings, capacitive sensors are a top choice.

The table below shows which material fits each need:

| Material Type | Application-Specific Requirement |

|---|---|

| Conductive Cloth | Works well on curved surfaces |

| Conductive Lycra | Good for soft, stretchy wearables |

| Kapton based flex circuit | Lasts long in tough places |

| Hybrid Materials | Gives balanced results |

Feature Comparison

Looking at features helps people pick the best sensor. Some sensors only sense touch. Others can measure force, pressure, or temperature. The kind of sensing you need is important. For example, you may need to sense temperature, pressure, or if something is there. What the object is made of also matters. If it is metal or not, you need the right sensor. How far away the object is also matters. Some sensors work close up. Others can sense from farther away.

Important features to look at are:

- Accuracy: How close the reading is to the real thing.

- Resolution: The smallest change the sensor can find.

- Repeatability: If the sensor gives the same answer every time.

- Durability: How long the sensor lasts and works well.

Selection Tips

Experts say to follow some steps when picking a sensor:

- Decide what you need to sense, like pressure or temperature.

- Check what the object is made of.

- Find out how far the object is.

- Read datasheets to learn about accuracy and other features.

- Do not make mistakes like putting the sensor in the wrong spot or using bad wires.

- Calibrate sensors often to keep data right.

- Use a checklist to set goals and plan for the future.

- Talk to experts and test products in real life.

Tip: Making sensors fit your needs and taking care of them stops data mistakes and keeps things working.

Choosing the right sensor makes devices work better and safer. Planning and getting advice from experts helps you get good results.

SOUSHINE Sensor

SOUSHINE sensors help many businesses stay safe and work better. These sensors have special features that others do not have. The table below shows how SOUSHINE sensors are different from regular ones:

| Feature | SOUSHINE Sensor | Typical Alternatives |

|---|---|---|

| Custom Fit | Yes | Limited |

| Real-Time Data | Yes | Sometimes |

| Weight Detection | Yes | Not always |

| Child Detection | Yes | Rare |

SOUSHINE sensors can be made to fit many jobs. They are built for each use, so companies can use them in lots of vehicles and machines. Real-time data means users see changes right away. This helps people make quick choices and stay safe.

Weight detection is a big feature. The sensor knows if someone or something is on a seat or surface. This helps safety systems in cars, buses, and trains. For example, the sensor can remind drivers to buckle up or check if a seat is empty.

Child detection is very helpful for families and buses. The sensor can warn drivers if a child is left in a seat. Parents like this because it keeps kids safe. Fleet managers also like it because it helps stop accidents.

SOUSHINE sensors help companies save money. Fleet managers say there are fewer repairs and less need to buy new sensors. The sensors last a long time, so there is less fixing needed. Drivers feel safer every time they use them.

Note: SOUSHINE sensors work for many fleets. For example, a taxi company with 100 cars saw more people using seat belts and fewer airbag problems after using SOUSHINE sensors.

SOUSHINE sensors work in many places. They help in cars, buses, taxis, and even smart furniture. The sensors give quick feedback, so users can act fast. This makes them good for safety, comfort, and control.

Main benefits of SOUSHINE sensors are:

- Custom fit for every job

- Real-time data for quick action

- Weight and child detection for safety

- Lower repair costs for fleets

SOUSHINE sensors help companies follow safety rules and make things better for users. Companies can count on these sensors to work well in many places.

Future of Tactile Sensors

Innovations

Tactile sensors are always changing as new ideas come up. Many scientists now make sensors that work faster and give better results. Some new ideas mix different sensing methods to make sensors work better. For example, a triboelectric-photoelectric hybrid tactile sensor reacts fast and gives steady results. This kind of sensor helps with things like typing and drawing on computers.

| Innovation Description | Application |

|---|---|

| Triboelectric-photoelectric hybrid tactile sensor with short response time and high output linearity | Human-computer interaction tasks such as text typing and figure drawing |

| Force tactile interaction technology for industrial robot force control | Robotics and teleoperation |

Engineers use force tactile interaction technology to help robots control how hard they grip. This helps robots when people control them from far away.

Some new systems use active mechanical tactile interaction. These systems can copy how hard or soft something feels. People use them in virtual reality and games. Flexible sliding sensors now act like human fingerprints. These sensors help people feel more in virtual reality and electronics.

Note: Many of these new ideas help tactile sensors work in more places, like robots and games.

Trends

Many trends are shaping the future of tactile sensors. Robots and machines are used more in many jobs. This means we need more tactile sensors to help machines touch and feel things. Hospitals and doctors use more tactile sensors in medical tools. These sensors help doctors do their jobs better and keep patients safer.

Phones and smartwatches now have tactile sensors. These sensors give users better feedback, like small vibrations. Smart clothes and wearables use tactile sensors to track fitness and help people get better after injuries. New materials let sensors bend and stretch. These new materials help sensors work in more products.

- Robots and machines need more tactile sensors.

- Hospitals use tactile sensors to help patients.

- Phones and gadgets use tactile sensors for better feedback.

- Smart clothes and wearables use tactile sensors for health.

- New materials make sensors flexible for more uses.

- The tactile sensor market will grow as AI, IoT, and new materials get better.

- More industries will want fast and smart tactile sensors as they use more machines.

- Research on self-healing and super-sensitive materials will bring new uses.

Tactile sensors will be used in more ways. They will help measure pressure and sense touch in many jobs. As technology gets better, these sensors will be even more important in our lives.

Touch sensors and tactile pressure sensors do different jobs. The table below shows what each sensor does:

| Sensor Type | Functionality |

|---|---|

| Tactile Pressure Sensor | Measures how strong and where the force is. It gives detailed feedback about how things touch. |

| Touch Sensor | Finds out if something is touched or not. It helps with user controls, like on touch screens. |

Knowing about each sensor type helps people pick the right one. Each sensor helps devices work better and brings new ideas to many fields. The table below shows what to think about when picking a sensor:

| Criteria | Description |

|---|---|

| Application Requirements | Figure out what forces you need to measure and how many sensors you need. |

| Operating Environment | Check for noise, temperature, humidity, and how clean the area is. |

| Resource Assessment | Look at space, money, and time for adding sensors. |

| Sensor Specifications | Check the range, how much force it can handle, how fast it works, and what sensing method it uses. |

People who want to know more about advanced sensors can look at SOUSHINE solutions or other new choices.

FAQ

What is the main difference between a touch sensor and a tactile sensor?

A touch sensor finds out if something touches a surface. A tactile sensor tells how much force is used and where it happens. Tactile sensors give more details than touch sensors.

Where do people use tactile pressure sensors?

People use tactile pressure sensors in robots, medical tools, cars, and smart furniture. These sensors help machines check force, make things safer, and give feedback for better control.

Can a touch sensor measure how hard someone presses?

A touch sensor only knows if there is contact. It cannot tell how hard someone presses. To measure force, you need a tactile pressure sensor.

Why do robots need tactile sensors?

Robots need tactile sensors to feel things. These sensors help robots pick up objects safely, not drop them, and change grip strength during tasks.

How do capacitive tactile sensors work?

Capacitive tactile sensors have two plates. When someone presses, the space between the plates changes. The sensor checks this change to find out the force.

Are tactile sensors used in healthcare?

Yes. Tactile sensors help watch patient pressure points in beds and chairs. They also help doctors in surgery by giving real-time force feedback.

What makes SOUSHINE sensors special?

SOUSHINE sensors can be made to fit different needs. They give real-time data and can tell weight. They also find children for safety. Many businesses use these sensors for better control and safety.

Can tactile sensors sense more than just pressure?

Some tactile sensors can sense temperature, movement, or texture. Multi-modal sensors mix different sensing skills for better feedback.