Call us: +86-137-2353-4866

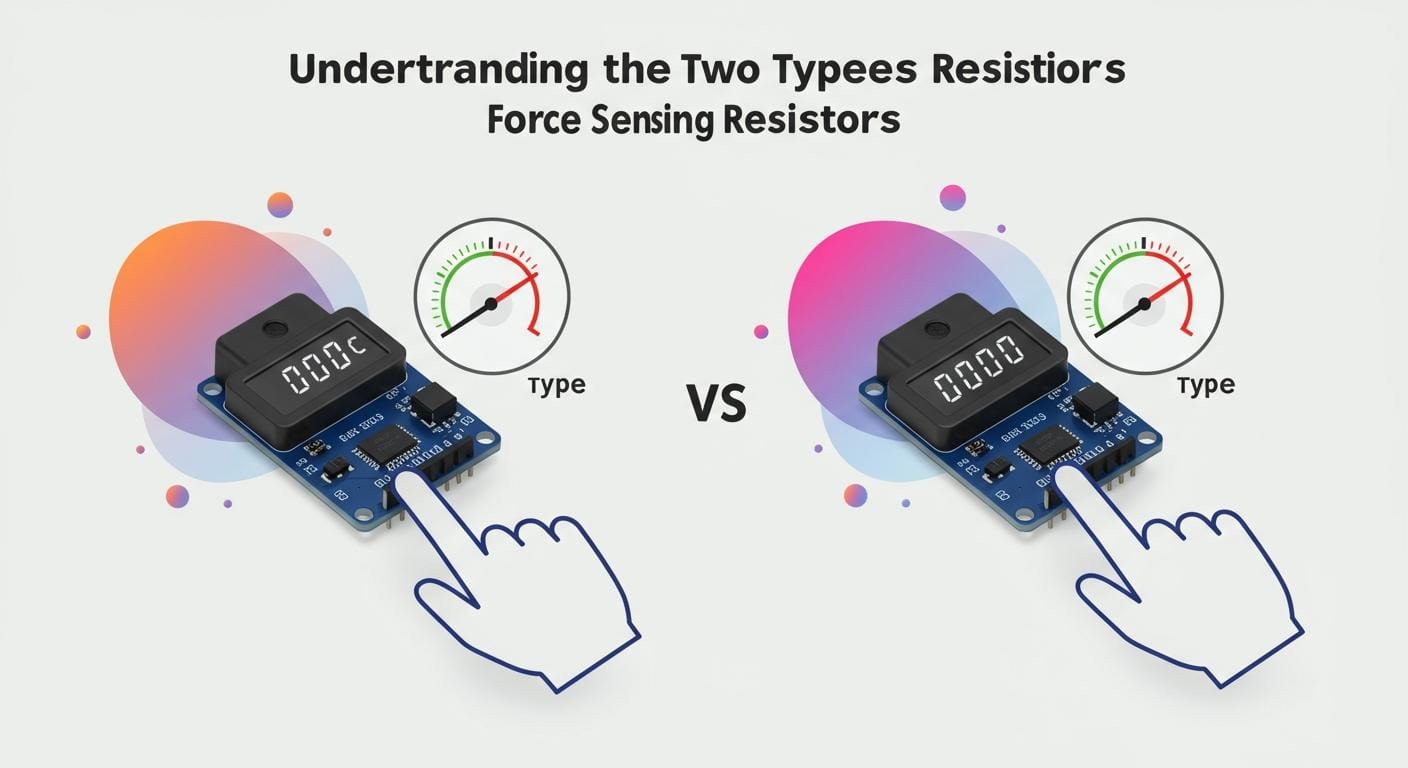

The two types of force sensing resistors are Shunt Mode and Thru Mode. They are important in new sensing technology. SOUSHINE is a leader in making force-sensing products. Choosing the right type is important for things like robots, medical tools, and user controls.

- More people want these sensors now. The market may reach almost USD 1.95 billion by 2033. It is growing at a rate of 9.1% each year.

| Industry | Application Description |

|---|---|

| Athletic Apparel | Finds foot pressure inside shoe insoles. |

| Medical Applications | Senses force to help with medicine and bed checks. |

| Robotics | Tells how much pressure robot arms use. |

| Inventory Control | Watches how much stuff is on shelves. |

| User Interface Controls | Works as buttons that you can change for different jobs. |

Table of Contents

Key Takeaways

Force sensing resistors, or FSRs, have two types. These are Shunt Mode and Thru Mode. Each type works best for different jobs. Shunt Mode FSRs can measure many force levels. This makes them good for cars and medical tools. Thru Mode FSRs are great at finding small force changes. They work well in robots and touch devices. SOUSHINE’s FSRs are very accurate and last a long time. They also use little power, so they are dependable. Picking the right FSR type depends on your project needs. You should think about how much force and how sensitive it must be. FSRs are in many things we use every day. They help make cars and medical tools safer and better. SOUSHINE lets you change FSRs to fit your project. This helps engineers make special sensors for their needs. You must set up FSRs the right way to get good results. This is important for them to work well in real life.

Force Sensing Resistor Basics

What Is a Force Sensing Resistor

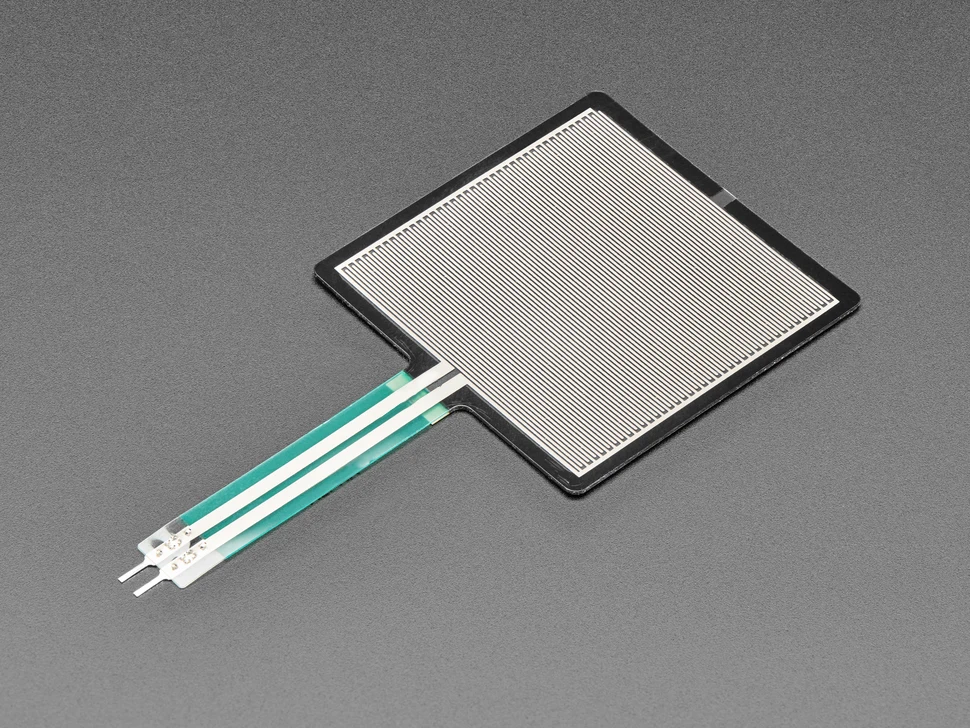

A force sensing resistor is a sensor that finds and measures force. SOUSHINE makes fsr sensors for many different industries. These sensors help measure force in things like medical devices and robots. They also work in smart electronics. The main job of a force sensing resistor is to change resistance when force is used. This makes it different from other pressure sensors. Other sensors use a bending part called a diaphragm to sense pressure.

SOUSHINE uses new force sensing resistor technology in its products. The company uses flexible polyester films for the base. These films make the sensor strong and bendable. The sensing layer uses silver-based or carbon-based inks. Silver-based inks help the sensor be more sensitive. Carbon-based inks make the sensor last longer. The sensors are made by screen printing ink onto the base. Careful building makes sure each fsr sensor works well.

| Category | Details |

|---|---|

| Substrate Options | Flexible polyester films provide strength and flexibility. |

| Conductive Materials | Silver-based inks for sensitivity, carbon-based inks for durability. |

| Manufacturing Process | Screen printing conductive inks onto substrates, followed by careful assembly. |

How FSRs Work

FSR sensors change resistance when force is put on them. The sensor has a special material between two thin layers. When someone presses the sensor, the ink touches the electrodes. This makes the resistance go down. More force means lower resistance. This simple idea lets fsr sensors measure many levels of force.

- FSR sensors change resistance when force is used.

- The sensing layer sits between two base layers.

- Pressure makes the ink touch the electrodes and change resistance.

This way of measuring force makes fsr sensors different from other types. Flexiforce and interlink sensors also change resistance, but they use different materials and designs. SOUSHINE’s force sensing resistor technology focuses on giving steady and repeatable force measurement.

Key Features

SOUSHINE’s fsr sensors have many good features for measuring force:

- High accuracy: SOUSHINE’s fsr sensors are more accurate than most others.

- Durability: The sensors last a long time, even with lots of use.

- Customization: SOUSHINE makes many shapes and sizes for different needs.

- Low power use: These sensors use little energy, so they are good for portable devices.

- Easy to add: SOUSHINE’s fsr sensors are simple to put into new or old products.

| Feature | SOUSHINE’s FSRs | Competitors’ FSRs |

|---|---|---|

| Accuracy | Superior | Varies |

| Durability | High | Moderate |

| Customization | Extensive | Limited |

| Low Power Consumption | Yes | Varies |

| Ease of Integration | Simple | Complex |

SOUSHINE also helps with calibration for each fsr sensor. Calibration lets users get the best force measurement. The company’s team can help with calibration and setup. This help makes SOUSHINE a good choice for people who need steady force measurement in their products, even those using flexiforce and interlink sensors.

The Two Types of Force Sensing Resistor

Force sensing resistor technology has two main types. These are Shunt Mode and Thru Mode. Engineers and designers pick the best type for each job. Both types are common fsr sensors. Each one uses a 2-terminal, 2-layer design. This design lets the sensor find force and change resistance.

Shunt Mode

Shunt mode force sensing resistors can sense many force levels. The force moves across the sensing area in this design. When you press on it, the resistance goes down. This type works well when force can be light or heavy. The response is not as even as some other types. But it can handle a big range of force. Many industries use this type because one sensor can sense many force levels.

SOUSHINE makes shunt mode force sensing resistors for many projects. These sensors help in cars, medical tools, and electronics. The wide force range makes them good for many jobs.

Thru Mode

Thru mode force sensing resistors are good for light force. The force goes straight through the sensing area. This design gives a more even response to force. Thru mode works best when you need to measure small force changes. The sensor reacts fast to light touches and gives steady results.

SOUSHINE makes thru mode force sensing resistors for careful jobs. Robots, factory machines, and touch controls use this type. The even response helps engineers get good data from every force.

Both shunt mode and thru mode use a 2-terminal, 2-layer design. The big difference is how each type reacts to force and how resistance changes.

The table below shows the main differences between the two types:

| Characteristic | Shunt Mode FSRs | Thru Mode FSRs |

|---|---|---|

| Force Sensitivity | Detects a wide range of forces | More linear, better for lighter forces |

| Resistance Characteristics | Less linear response | More linear response |

| Applications | Broader applications | Suited for specific lighter applications |

SOUSHINE supports both types of force sensing resistor. The company helps customers pick the right sensor for each job. This help makes sure every project gets the best sensor.

Shunt Mode FSR

Principle

Shunt Mode force sensing resistors let current move across the sensing area. When you press on the sensor, resistance gets lower. The sensor starts working with a small force, about 20 to 50 grams. Small sensors can measure up to 1 kilogram. Bigger sensor arrays can measure up to 50 kilograms. This big range lets Shunt Mode find both still and moving forces. The sensing layer feels pressure changes and gives a clear signal for each force.

| Sensor Model | Force Measurement Range | Notes |

|---|---|---|

| FSRtek Matrix Force Sensing Resistor 16×16 | 200 grams to 50 kilograms | Can sense light presses at 200g; works up to 50kg; easy to use and not expensive |

- Shunt Mode force sensing resistors start working at 20–50 grams.

- Small sensors measure up to 1 kilogram.

- Large sensor arrays measure up to 50 kilograms.

This way lets engineers use one sensor for many jobs. The sensing area reacts fast to force, so it works for both light and heavy pressure.

Pros

Shunt Mode force sensing resistors have many good points. They give accurate current readings, which helps with exact results. Their small size fits into tight spaces. These sensors save energy, so parts last longer. Shunt Mode can also spot too much current, which keeps devices safe. These sensors do not cost much, so they are good for projects with small budgets.

| Advantage | Description |

|---|---|

| Accurate Current Measurement | Provides precise resistance values and low tolerance for accurate current readings. |

| Cost-Effective Solution | More affordable than Hall-effect sensors, making them suitable for budget-conscious projects. |

| Compact Design | Small size facilitates integration into space-constrained applications. |

| Energy Efficiency | Optimizes power usage, reducing waste and extending component lifespan. |

| Overcurrent Protection | Detects excessive current flow to prevent damage, enhancing safety. |

Shunt Mode force sensing resistors work in many areas. They help in cars, electronics, and medical tools. They are used for weight checks, machine setup, and touch controls.

Cons

Shunt Mode force sensing resistors also have some downsides. They can take up a lot of space, which is not good for small designs. They make heat, which can hurt how well they work. The design can be hard because engineers must think about filters and different parts. Accuracy can change if the temperature changes, so good parts are needed for best results.

| Limitation | Description |

|---|---|

| Large Footprint | Shunt resistors and their components take up significant PCB space, which can be a constraint in compact designs. |

| Heat Generation | Power dissipation leads to heat, affecting performance and potentially requiring additional cooling solutions. |

| Design Complexity | Requires expertise in filter design and consideration of component variations, increasing design complexity. |

| Accuracy Limitations | Temperature changes and resistor precision can affect accuracy, necessitating high-quality components, which can be expensive. |

Engineers need to think about these things when picking a force sensing resistor. Shunt Mode gives lots of choices, but design picks can change how well it works and how long it lasts.

Uses

Shunt Mode force sensing resistors are used in many fields. Engineers pick these sensors for jobs that need to measure many force levels. SOUSHINE gives Shunt Mode FSRs to lots of industries. These sensors help make things safer and easier to use.

Automotive Safety

Car makers put Shunt Mode FSRs in seats to check if someone is sitting. The sensor tells the car if the seat is full or empty. Then, the car can turn airbags on or off. These sensors are also in brake and gas pedals. They measure how hard the driver pushes. This helps make cars safer.

Consumer Electronics

People who make devices use Shunt Mode FSRs in touchpads and game controllers. The sensor knows how hard you press a button. This lets users have more control. Remote controls and smart home gadgets use these sensors too. The sensor changes how it works based on how hard you press.

Medical Devices

Hospitals use Shunt Mode FSRs in beds to see if a patient moves or gets up. This helps nurses act fast. Nurses use these sensors in infusion pumps. The sensor checks the force to make sure the pump works right. Physical therapy tools use these sensors to track how much force a patient uses.

Industrial Equipment

Factories use Shunt Mode FSRs on assembly lines. The sensor checks if parts fit together with the right force. This keeps the quality high. These sensors are also in packaging machines. They make sure packages close with the right pressure.

Robotics

Robots use Shunt Mode FSRs to feel touch. The sensor helps robots pick up things without breaking them. It also helps robots change their grip if the object is heavy or light.

SOUSHINE has Shunt Mode FSRs in many shapes and sizes. The company helps people pick the best sensor for each job. SOUSHINE’s sensors work well in hard places and last a long time.

| Application Area | Example Use Case | Benefit Provided |

|---|---|---|

| Automotive | Seat occupancy, pedal force | Improved safety |

| Consumer Electronics | Touchpads, controllers | Better user control |

| Medical Devices | Patient beds, infusion pumps | Reliable monitoring |

| Industrial | Assembly, packaging | Quality assurance |

| Robotics | Gripping, object handling | Adaptive touch sensing |

Shunt Mode FSRs from SOUSHINE help many fields fix real problems. The sensors give good force data. This data makes products safer and easier to use.

Thru Mode FSR

Principle

Thru Mode force sensing resistors let force go straight through the sensing area. This design helps the sensor notice even small touches. The sensing layer is between two electrodes. When you press down, resistance gets lower. Thru Mode is good for measuring tiny changes in force. The sensor can find a force as small as 0.1 newtons. It can sense from 0.1 newtons up to 100 newtons.

| Specification | Value |

|---|---|

| Minimum Force Detection | ~0.1N |

| Sensitivity Range | ~0.1N–100N |

This type gives steady results for small force changes. The sensing area reacts fast, so it is great for jobs that need quick and accurate force checks.

Pros

Thru Mode force sensing resistors have many good points for engineers and designers. The best thing is they can sense very light force. This makes them perfect for jobs that need careful force checks. The sensor reacts fast when force changes, which helps in real-time uses. Thru Mode gives a more even output, so users can trust the readings.

- Senses small force changes with high sensitivity

- Reacts quickly to force

- Gives more even output for better accuracy

- Works well in robotics, automation, and touch controls

SOUSHINE has Thru Mode force sensing resistors in many shapes and sizes. The company can make special designs for unique projects. These sensors fit into robot fingers, limit sensors, and human interface devices.

| Application Area | Specific Uses |

|---|---|

| Robotics | Robotic Finger Tips, Assembly Parts Detection |

| Industrial Automation | Dynamic Limit Sensor, Motor Speed Control |

| Touch Interfaces | Human interface devices, Interactive toys |

| Automotive | Seat Occupancy Detection, Electronic Throttle |

Cons

Thru Mode force sensing resistors also have some problems users should know:

- Standard PTF materials may not last long; they can wear out

- Output is not always even for every version

- Not as exact as strain gauges or load cells

- Output depends on how good the support circuit is

- Force sensitivity can change in different parts of the sensor

- Hysteresis and repeatability can make results less steady

- Resistance value changes if the temperature changes

- Some materials do not last long; performance can get worse

- Prints can tear or peel off, so the sensor can break easily

Users should pick the right sensor for the job and check the environment before using Thru Mode force sensing resistors.

Uses

Thru Mode force sensing resistors are used in many fields. These sensors help when you need to measure small changes in force. Engineers pick them for jobs that need careful pressure checks. SOUSHINE makes Thru Mode FSRs that work well for these uses.

Robotics

Robots need to feel touch and pressure to work safely. Thru Mode FSRs help robot hands know how much force they use. This helps robots pick up breakable things without damage. On assembly lines, robots use these sensors to check if parts fit together right.

Industrial Automation

Factories use Thru Mode FSRs to control machines. These sensors help machines stop or slow down if they sense something. Workers use them to check if conveyor belts move things with the right pressure. Thru Mode FSRs also help check packaging by measuring force.

Sensitive Touch Interfaces

Touch screens and panels use Thru Mode FSRs to sense light touches. These sensors help devices react fast to what users do. Designers put them in medical tools, smart home controls, and toys. The sensors help make devices easy and smooth to use.

Healthcare Devices

Medical tools use Thru Mode FSRs to watch patient movement. Beds and chairs use these sensors to know when a patient sits or stands. Physical therapy tools use them to check how much force a patient uses.

Automotive Systems

Car makers use Thru Mode FSRs in seats and controls. The sensors help tell if someone is sitting in a seat. They also check how hard a driver pushes a button or pedal.

SOUSHINE makes Thru Mode FSRs in many shapes and sizes. The company works with engineers to make special sensors for different jobs. SOUSHINE’s sensors give quick and steady results, which helps make things safer and better.

| Application Area | Example Use Case | Benefit Provided |

|---|---|---|

| Robotics | Gripper force feedback | Safe object handling |

| Industrial Automation | Conveyor pressure detection | Improved control |

| Touch Interfaces | Medical device panels | Quick response |

| Healthcare | Patient monitoring beds | Reliable tracking |

| Automotive | Seat occupancy sensors | Enhanced safety |

Thru Mode FSRs from SOUSHINE help many fields fix real problems. These sensors give clear force data, which helps make better and safer products.

Key Differences

Comparison Table

The table below shows how Shunt Mode and Thru Mode force sensing resistors are different. This table helps engineers and designers pick the best type for their work.

| Feature | Shunt Mode FSR | Thru Mode FSR |

|---|---|---|

| Force Range | Wide (light to heavy) | Narrow (light to moderate) |

| Sensitivity | Good for many force levels | High for small force changes |

| Sensing Response | Less linear | More linear |

| Typical Applications | Automotive, medical, electronics | Robotics, automation, touch |

| Cost | Lower | Slightly higher |

| Integration | Simple | Simple |

This table gives a fast look at how each force sensing type works in different jobs.

Performance

Shunt Mode force sensing resistors are good for jobs that need to measure many force levels. They can sense both light and heavy force. The sensing area reacts to different forces, but the response is not always even. This type is best when the force can change a lot. Thru Mode force sensing resistors are better for small force changes. They give a more even response. This helps when you need to track light force with high accuracy. The sensing layer in Thru Mode reacts fast to small force. This makes it great for robots and touch controls.

Engineers use Shunt Mode when they need to measure a big range of force. They use Thru Mode when they need to sense small force changes. Both types use a 2-terminal, 2-layer design. The main difference is how each type handles force and how the sensing layer reacts.

Cost

Shunt Mode force sensing resistors cost less than Thru Mode. This makes Shunt Mode a good pick for projects with a small budget. Thru Mode costs a bit more because it works better for small force changes. The extra cost is because the sensing layer needs to be more sensitive. Both types are cheaper than other force sensing choices. SOUSHINE sells both types at prices that work for many projects.

Picking the right force sensing type depends on the job, the force range needed, and the budget. SOUSHINE helps customers choose the best sensor for each use.

Suitability

Picking the right force sensing resistor depends on what your project needs. Shunt Mode and Thru Mode FSRs work for different jobs. Engineers and designers should think about force range, sensitivity, and device type before they choose.

Shunt Mode FSRs

Shunt Mode FSRs are good for projects that need to measure many force levels. These sensors can handle both soft and strong pressure. Many industries use them because they work well in lots of places. Car engineers use Shunt Mode FSRs in seat sensors and pedals. Medical makers use them in beds and therapy tools. Designers use them in touchpads and controllers. Shunt Mode FSRs also work in machines that check assembly or packaging force.

Thru Mode FSRs

Thru Mode FSRs are best for jobs that need to sense small forces. These sensors react fast to gentle touches. Robotics engineers use Thru Mode FSRs in grippers and robot fingers. Factory teams use them in limit sensors and conveyor controls. Designers use Thru Mode FSRs in panels and smart gadgets. Healthcare engineers use them in patient monitors and therapy gear. Thru Mode FSRs also help cars find light pressure, like seat checks.

Tip: Always match the sensor’s force range and sensitivity to the job. Using the wrong sensor can give bad data or miss signals.

Key Factors for Selection

- Force Range: Shunt Mode works for many force levels. Thru Mode is best for light force.

- Sensitivity: Thru Mode is better for small changes. Shunt Mode works for both soft and strong force.

- Application Environment: Shunt Mode works in tough places. Thru Mode is best in safe, clean spots.

- Integration: Both types are easy to add to new or old products.

| Application Need | Best FSR Type | Example Use Case |

|---|---|---|

| Wide force measurement | Shunt Mode | Car seat sensors |

| Light touch detection | Thru Mode | Robotic grippers |

| Fast response | Thru Mode | Touch panels |

| Heavy-duty environments | Shunt Mode | Industrial machines |

SOUSHINE sells both kinds of FSRs. The company helps customers pick the right sensor for each job. Their team gives advice on picking, setting up, and adding sensors. This help lets engineers and designers get the best results for their products.

Note: For special needs, SOUSHINE can make FSRs in custom shapes and sizes.

Choosing the right FSR makes devices work better and easier to use. Matching the sensor to the job gives good force measurement and helps products last longer.

Applications

Automotive

SOUSHINE force sensing resistors are important in today’s cars. Engineers use these sensors to make cars safer and easier to control. The sensors help in many car systems:

- Seat belt sensors turn on when someone buckles up. The system tells the car’s computer.

- Seat occupancy sensors check if a person is in the front seat. The car uses this to decide if airbags should go off in a crash.

- Braking systems have force sensors under the brake pedal. These measure how hard you press, which helps the brakes work well.

These uses help cars react to real-life events. The sensors help keep drivers and passengers safe. SOUSHINE makes each sensor strong so it works well in cars.

Healthcare

Force sensing resistors are used in many healthcare tools. They help doctors and nurses watch patients and give better care. The sensors give feedback in prosthetics, which helps people move more naturally. In wound care, the sensors help put the right pressure on bandages, which lowers the chance of problems.

FSR sensors can connect to a smart device or app that tells you when force changes. This means if a patient gets out of bed, you will know right away.

Healthcare teams use these sensors in different ways:

- Patient beds use sensors to check if someone is in bed and tell staff.

- Prosthetics use sensors to sense pressure and give feedback.

- Wound care tools use sensors to make sure bandages have the right pressure.

| Aspect | Description |

|---|---|

| Accurate Measurement | FSRs give exact data about force in medical tools. |

| Monitoring | They help watch patients and how devices work all the time. |

| Control | FSRs help control medical tools, making them safer and better. |

| Patient Safety | By finding force changes, FSRs help keep devices safe and working right. |

| Operational Efficiency | Using FSRs helps hospitals work better and care for patients more easily. |

These sensors help doctors and nurses give better care and keep patients safe.

Robotics

Robotics engineers use force sensing resistors to give robots a sense of touch. The sensors find force and help robots change what they do. This lets robots hold things gently and with care.

- Robots can find or measure how fast force changes.

- Robots can find or measure how much force changes.

- Robots can tell when they touch something.

- Robots can find when force is high enough to start an action.

Force sensors help robots be more exact and careful. By always checking the force they use, robots can make small changes right away. This helps them do even very detailed jobs well.

Robots also use these sensors to work safely with people. The sensors find bumps and sudden forces. This helps robots stop or move away to keep people safe.

These sensors let robots work with people without hurting them by finding bumps and sudden forces.

SOUSHINE gives sensors that help robots do hard jobs and work safely with humans.

Consumer Electronics

SOUSHINE force sensing resistors are used in many devices. These sensors help gadgets react to touch and pressure. They make products simple and reliable.

Phones and tablets use FSRs in their screens. The sensors know how hard you press. This lets the device do different things. A light tap can open an app. A hard press can show more choices.

Game controllers use FSRs in their buttons. Players press soft or hard to control speed or power. This makes games feel more real and fun.

Fitness trackers and smartwatches use FSRs too. The sensors check grip strength or finger pressure. This helps people watch their health and exercise.

Remote controls use FSRs for soft buttons. You can change the channel or volume with a gentle press. The buttons feel nice and work fast.

SOUSHINE FSRs help designers make products that react quickly and correctly to what you do.

The table below shows how SOUSHINE FSRs are used in electronics:

| Device Type | FSR Application | User Benefit |

|---|---|---|

| Smartphone/Tablet | Pressure-sensitive screen | More control, easy use |

| Game Controller | Pressure-sensing buttons | Better gameplay |

| Fitness Tracker | Grip/pressure tracking | Health monitoring |

| Remote Control | Soft-touch buttons | Comfortable operation |

| Smartwatch | Touch interface | Quick response |

SOUSHINE has FSRs in many shapes and sizes. Engineers pick the best sensor for each gadget. The sensors use little energy, so they are good for portable things.

- FSRs help keep devices safe by finding wrong pressure.

- They help devices last longer by saving wear on parts.

- The sensors make products more fun and simple.

SOUSHINE gives advice and special sensor designs to makers. The company helps bring new ideas to consumer electronics.

Choosing Force Sensing Resistors

Factors

Picking the right force sensing resistor takes careful thought. You need to look at many things before you choose. Each thing can change how well the sensor works and how long it lasts. The table below shows the most important things to think about:

| Factor | Description |

|---|---|

| Durability | The sensor must handle repeated force and rough use. |

| Environment | The sensor should resist dust, moisture, and dirt. It must work in both clean and harsh conditions. |

| Form Factor | The size and shape must fit the device. Thin and flexible sensors work well in small spaces. |

| Repeatability | The sensor should give the same result each time for the same force. |

| Sensitivity | The sensor must detect the right range of force for the application. |

| Cost | The sensor should meet project needs without going over budget. |

Where you use the sensor matters a lot. Hot or cold weather can change how the sensor works. Some sensors do better in heat or cold. Wet air and dust can also make a difference. A sensor that is sealed will last longer in hard places.

Tip: Always pick a sensor that is strong enough and sensitive enough for your project’s needs.

Shunt Mode and Thru Mode force sensing resistors are used for different jobs. Shunt Mode can measure both soft and strong force. Thru Mode works best for light touches and small forces. Picking the right sensor type is important for good results.

- Measuring force well in prosthetics helps people move and keeps their limbs safe.

- The kind of FSR you use can change how comfortable and useful it is.

- FSRs are cheap and simple to use, but you need the right accuracy for your project.

SOUSHINE makes sensors you can trust and change for your needs. Their team can help you pick the best sensor for any project.

FAQ

What is the main difference between Shunt Mode and Thru Mode FSRs?

Shunt Mode FSRs can measure many different force levels. Thru Mode FSRs are better for finding small, exact forces. Each type works best for certain jobs.

Can SOUSHINE customize FSRs for unique projects?

Yes. SOUSHINE can make FSRs in special shapes and sizes. Their team helps engineers pick the right sensor for each project.

How long do SOUSHINE FSRs last in daily use?

SOUSHINE FSRs are made with strong materials. They can handle being used over and over again. Most sensors will last for years if you take care of them.

Are FSRs easy to add to existing products?

Yes. SOUSHINE FSRs have a simple two-wire design. Engineers can put them into new or old devices without much trouble.

What industries use SOUSHINE FSRs most often?

Car makers, hospitals, robot builders, and gadget companies use SOUSHINE FSRs. These sensors help make things safer and easier to use.

How do FSRs handle extreme temperatures or moisture?

SOUSHINE makes FSRs for many kinds of places. Some sensors can work in heat, cold, or wet spots. Always look at the product details to know what each sensor can handle.

Do FSRs need calibration before use?

Calibration helps the sensor give better results. SOUSHINE gives tips and help for setting up calibration. Setting up the sensor right makes sure you get good force readings.

Can FSRs measure both static and dynamic forces?

Yes. SOUSHINE FSRs can find both steady and changing forces. This makes them useful for many real-life jobs.