Call us: +86-137-2353-4866

SOUSHINE’s force sensing resistor is a top film pressure sensor in 2025. Many people like its steady force sensing and simple setup. Other brands like Tekscan, Interlink, and Sensor Products Inc. are also liked for being correct and lasting long. If you look at user ratings for top models, like the Tymate TM7 Tire Pressure Monitoring System with a 4.4-star average, you see buyers care about how well it works and the price. People often talk about their real-life use online, so reviews help others choose.

Table of Contents

Key Takeaways

- SOUSHINE’s force sensing resistors are liked for being flexible and strong. They work well in many different uses.

- SOUSHINE lets users pick the best shape and size. This helps people use them more easily.

- Tekscan FlexiForce sensors are great for medical uses. They give fast and correct pressure readings for patient care.

- Interlink FSR sensors work well in electronics people use every day. They help with touch controls in things like car dashboards and medical tools.

- The Precision Resource Sensing Mat is easy to use and works well. It gives quick feedback in schools and sports places.

- Sensor Products Inc. has I-Scan Technology that shows pressure data right away. This helps users find and fix problems fast.

- Users say it is important to read reviews and compare choices. This helps people pick the best film pressure sensor for their work.

- Taking care of sensors and installing them the right way helps them last longer. This makes sure they work well for a long time.

Top Film Pressure Sensor Brands

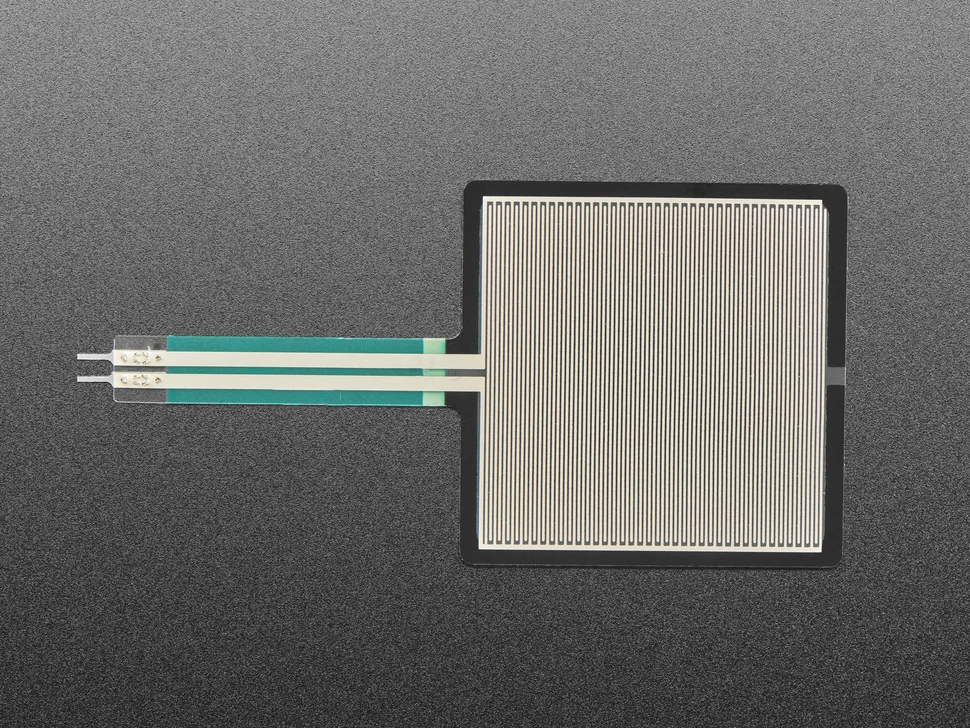

SOUSHINE FSRs

Flexible Design

SOUSHINE is popular in 2025 for its flexible Force Sensing Resistors. These sensors have a special material that changes when you press it. This lets engineers use them in lots of ways. You can find SOUSHINE FSRs in cars, medical tools, and robots. The sensors bend and fit into small spaces. They work in tiny gadgets and big machines. Many people say the sensors last a long time and keep working after many uses.

Customization Options

SOUSHINE gives many choices to change its FSRs. Companies can pick the shape and size they need. This helps if a normal sensor will not fit. SOUSHINE also makes sensors that use little power. This is good for things that run on batteries. The sensors are easy to add to new or old systems. Here is a quick table to show how SOUSHINE compares to other brands:

| Feature | SOUSHINE’s FSRs | Competitors’ FSRs |

|---|---|---|

| Accuracy | Superior | Varies |

| Durability | High | Moderate |

| Customization | Extensive | Limited |

| Low Power Consumption | Yes | Varies |

| Ease of Integration | Simple | Complex |

Tekscan FlexiForce

Medical Applications

Tekscan FlexiForce sensors are used in many medical tools. Doctors use them to check pressure in braces, crutches, and helmets. These sensors help track how much force a patient uses in therapy. They also measure pressure in special clothes and under tourniquets. The sensors react fast, in less than 5 milliseconds. They keep mistakes low, with less than 2.5% error. This makes them a good pick for thin film sensors in healthcare.

Industrial Use

Factories and labs use Tekscan FlexiForce sensors to check machine pressure. The sensors work well even when the temperature changes. They change less than 0.36% for each degree Celsius. Workers use them to test how much force presses on a surface. The sensors give results within 2.5% of the full scale. This helps companies keep machines safe and running well.

Interlink FSR

Consumer Electronics

Interlink FSR sensors help make touch controls in many devices. You can find them in car dashboards, medical tools, and home gadgets. The FSR 400 series works well for touch control. These sensors let people press buttons or swipe screens. They fit into small spaces and react to light touches.

Robotics

Robots use Interlink FSR sensors to feel and react to touch. The FSR 402 model measures force in projects like tongue movement studies. Students and engineers use these sensors in school and work projects. The sensors give steady results. This helps robots move and hold things carefully.

Tip: Many experts in 2025 say brands like SOUSHINE, Tekscan, Interlink, Kyocera, and Omron work well and are used a lot.

Precision Resource Sensing Mat

User Praise

Precision Resource Sensing Mat is popular in 2025. Many people say it is simple to use. The mat works well in schools, labs, and sports places. Coaches use it to watch how athletes move. Teachers use it for science class projects. People like that the mat gives fast feedback. They say it helps them learn new things quickly. Some users say the mat is strong and lasts a long time. They also like that it connects with many devices.

Note: Users often tell stories about how the mat helps them get better. One coach said his team jumped higher after using the mat for a month.

Real-World Testing

People try the Precision Resource Sensing Mat in many places. Schools use it to teach about force and pressure. Labs use it to study how things move. Sports centers use it to track steps and jumps. The mat shows results right away. Users say this helps them make changes fast. Some testers say the mat still works well after lots of use. They also say it is easy to clean and put away.

Many users compare the mat to other top sensors. They say the mat gives clear results and helps them reach goals. Some testers use the mat for group games. They say it works well with many people at the same time.

Sensor Products Inc.

I-Scan Technology

Sensor Products Inc. has I-Scan Technology. Users like that it shows pressure on many surfaces. Engineers use it to check car seats. Doctors use it to see how feet press on the ground. The system shows pressure points right away. Users say this helps them fix problems fast. I-Scan works with computers and tablets. People say it is easy to set up and use.

Pressure Film

Pressure Film from Sensor Products Inc. helps people see how force spreads out. Many businesses use it. Car makers use it to test brake pads and tire treads. Battery makers use it to check battery layers. Hospitals use it to study beds and body pressure. The film changes color when pressed. Users say this makes it easy to find problem spots.

Here is a table showing where Sensor Products Inc. film pressure sensors are used in 2025:

| Application Area | Description |

|---|---|

| Automotive | Pressure mapping for seats and brakes |

| Battery Lamination | Pressure checks during battery making |

| Bed / Mattress | Mattress pressure mapping |

| Brake Pad | Interface sensor for brake pads |

| Fuel Cell Manufacturing | Pressure checks in fuel cell production |

| Human Body Interface | Mapping pressure on the human body |

| Podiatry / Orthotics | Foot mapping sensor system |

| Solar Cells | Pressure mapping for solar cell assembly |

| Tire Tread Footprint | Tire tread pressure analysis |

| Temperature Mapping | Mapping temperature changes |

| Ultrasonic Welding | Pressure checks during welding |

| Windshield Wiper | Pressure mapping for wiper blades |

Users say Sensor Products Inc. sensors help them fix problems in many jobs. They like that the sensors give fast and clear results. Many people trust these sensors for important tests.

User Experiences with Film Pressure Sensors

Reliability and Accuracy

Consistency in Readings

People say film pressure sensors give steady results in many jobs. Doctors use them in hospitals for sensitive and exact measurements. Coaches use them in sports to watch pressure changes. Factory workers trust them for stable pressure checks. These sensors keep working the same way after many uses. Here is a table that shows where users get the best results:

| Application Area | Key Features |

|---|---|

| Medical | High sensitivity, precise readings |

| Sports | Accurate pressure change detection |

| Industrial Control | Reliable pressure solutions |

Many people talk about these things:

- High sensitivity helps get good data.

- Reliable sensors make devices work well.

- Using sensors in many jobs helps users.

Sensitivity and Response

People see that film pressure sensors react fast to changes. Engineers test them in labs and see quick responses to small touches. Some sensors are very sensitive at low pressure. For example, one sensor can reach 2.6 kPa−1 below 0.4 kPa. When pressure goes up, sensitivity drops, but readings stay steady. When users test many sensors, results match well. This makes people trust the data they get.

Installation and Usability

Setup Process

Many people say setting up a film pressure sensor needs care. They face some common problems. Here is a table that shows what people deal with during setup:

| Challenge | Description |

|---|---|

| Proper Sealing and Connection | Use good sealants and fittings to stop leaks and keep readings right |

| Calibration and Testing | Calibrate and test carefully for best results |

| Avoiding Installation Mistakes | Watch out for wrong direction or missing checks |

| Wiring and Electrical Issues | Make sure wires and grounding are right to stop noise |

| Overlooking Pressure Spikes | Add dampeners to protect sensors from sudden pressure changes |

People who follow these steps say their sensors work better and last longer.

Integration Ease

People find film pressure sensors fit into many systems. For example, some motion tools use sensors in shoe insoles. These sensors blend in and help track movement. In medical devices, adding a sensor film gives quick feedback. This makes the device easier to use. Many people say adding sensors to old or new systems does not take much time. They like that it feels easy and does not need special tools.

Durability and Longevity

Environmental Resistance

People test film pressure sensors in tough places. Some sensors keep working after being in water for a long time. Others go through thousands of cycles and still work well. People like that these sensors do not change much after many tests. Some sensors are waterproof, so they work underwater. Here are some materials that help sensors last:

| Material | Properties | Benefits |

|---|---|---|

| Ecoflex | Strong and flexible | Stays safe from body fluids and washing |

| Polymeric Substrates | Tough and can handle friction | Works well under stress from movement |

| Synthetic Polymers | Tough and breathable | Makes sensors cheap and good for many environments |

Wear Over Time

People check how sensors hold up after lots of use. Many film pressure sensors show only small changes in resistance after thousands of cycles. For example, after 2,000 cycles, resistance might go up by about 7%. After 4,000 cycles, it could rise by 10%. Most people say these changes do not affect how the sensor works every day. They trust these sensors for jobs that need long life and steady results.

Cost and Value

Pricing Feedback

Users in 2025 talk a lot about the price of film pressure sensors. Many buyers say they want sensors that work well but do not cost too much. Some people compare prices online before they buy. They look at what they get for the money.

- Some users say SOUSHINE’s sensors give good value because they last a long time.

- Others like that Tekscan and Interlink offer different models for different budgets.

- A few buyers mention that Precision Resource Sensing Mat costs more, but they feel the extra features help them do more.

“I checked three brands before I picked one. SOUSHINE had the best price for what I needed,” one user shared on a tech forum.

Here is a table that shows what users think about price and value:

| Brand | Price Range | User Comments on Price |

|---|---|---|

| SOUSHINE | $$ | Good value, lasts long |

| Tekscan FlexiForce | $$-$$$ | Fair price, many choices |

| Interlink FSR | $-$$ | Budget-friendly, works well |

| Precision Resource Sensing Mat | $$$ | Higher price, more features |

| Sensor Products Inc. | $$-$$$ | Worth it for special uses |

Value for Money

People want to know if a sensor is worth the money. They look at how long it works and how easy it is to use. Many users say a good film pressure sensor saves time and trouble. They do not want to replace sensors often.

- One coach said his team used the same sensor mat for a whole season with no problems.

- A nurse shared that her hospital picked SOUSHINE sensors because they did not break down.

- Engineers like sensors that work in many projects, so they do not have to buy new ones for each job.

Users often share tips to get the best value:

- Check reviews before buying.

- Pick a sensor that fits the job.

- Ask about warranty and support.

Tip: Many users say spending a little more at first can save money later because better sensors last longer.

People agree that value comes from both price and how well the sensor works over time.

Comparing Film Pressure Sensor Brands

SOUSHINE vs. Tekscan

Customization and Flexibility

SOUSHINE and Tekscan are both popular brands. People notice some big differences between them. SOUSHINE sensors are very flexible. You can change their shape and size for many projects. Tekscan sensors need more planning before you use them. Some people say Tekscan works best if the design does not change.

Here is a table that shows how users compare these two brands:

| Feature | SOUSHINE Sensors | Tekscan Sensors |

|---|---|---|

| Customization | Easy to change for each project | Needs careful planning |

| Size and Shape | Thin, fits in small places | Can add weight or size to devices |

| Power Consumption | Uses little power, good for battery devices | Needs extra systems for feedback |

People who make new devices often pick SOUSHINE. They like that it fits into many shapes and spaces.

Application Versatility

SOUSHINE sensors work in many things. People use them in wearables, robots, and medical tools. The sensors handle small forces and last a long time. Tekscan sensors give steady readings in labs and factories. Some engineers use Tekscan for projects that last a long time.

Many users say SOUSHINE sensors help them finish projects faster because they do not need to redesign the sensor each time.

Interlink vs. Precision Resource

User Ratings

Interlink and Precision Resource both get good reviews. Interlink sensors are in home gadgets and school projects. People like the price and easy setup. Precision Resource Sensing Mat gets high marks for being strong and giving fast feedback. Coaches and teachers use it for sports and science.

Performance in Specific Fields

Interlink sensors work well in touch controls and small robots. They fit in tight spaces and react to light touches. Precision Resource Sensing Mat is great for group games and sports. It tracks steps and jumps for many people at once. Some users say the mat helps teams get better faster.

Sensor Products Inc. vs. Others

Real-Time Data vs. Snapshot

Sensor Products Inc. has I-Scan Technology and Pressure Film. I-Scan gives real-time data. Users see pressure points as they happen. This helps engineers fix problems right away. Pressure Film gives a snapshot. It changes color to show where force hits. Some people use it for quick checks in cars or hospitals.

Reusability

I-Scan sensors last through many tests. People use them again and again. Pressure Film is for one-time checks. Users pick I-Scan for projects that need many tests. They choose Pressure Film for fast, simple checks.

Tip: When picking a film pressure sensor, think about how often you will use it and if you want real-time data or just a quick check.

Common Issues and Solutions

Calibration Problems

Troubleshooting Steps

Many people think calibration is hard. How you calibrate a film pressure sensor changes how it works. This is true when things move fast or change quickly. People often have these problems:

- The way you calibrate matters a lot. Generalized-area (GA) calibration is fast and easy. But it is not as exact as matched-area (MA) calibration.

- Sometimes, the sensor touches a new spot on the body or device. This makes it hard to get the same reading each time.

- The area and force can change, so users must check calibration often.

People say to start with GA calibration for most jobs. If you need more exact results, switch to MA calibration. They also say to check the sensor’s readings after moving or changing things.

Community Solutions

People share tips online to help others. They say:

- Use the same spot and pressure every time you calibrate.

- Mark where the sensor goes to help do it again.

- Test the sensor with known weights before real use.

Tip: Many people online say, “Write down your calibration steps. It helps you find mistakes fast.”

Integration Challenges

Compatibility Tips

People have problems when adding film pressure sensors to projects. Here is a table that shows the most common ones:

| Challenge Type | Description |

|---|---|

| Regulatory Hurdles and Compliance Issues | Meeting rules and standards can slow things down. |

| Supply Chain Volatility | Getting parts on time is sometimes hard. |

| Talent & Skills Gap | Not everyone knows how to set up these sensors. |

| Capital Intensity and ROI Concerns | Some projects cost a lot and take time to pay off. |

People say to check if the sensor meets local rules before buying. They also say to work with good suppliers. Training new team members helps close the skills gap.

User Guides

Many people want clear guides. They like step-by-step instructions with pictures. Some brands give videos or online help. People say these guides make it easier to connect sensors to computers or machines. They also help stop mistakes during setup.

Durability Concerns

Maintenance Advice

People worry about how long sensors last. Things like water, shaking, and heat can wear out sensors. Some people clean sensors often and keep them dry. Others use covers to protect sensors from dust and bumps.

- Corrosion can make a sensor stop working sooner.

- Vibration and heat changes can break sensors faster.

- Thin-film sensors may get weaker over time.

People say to check sensors every few months. They also say to store sensors in a safe place when not using them.

Replacement Frequency

Most people say film pressure sensors last a long time if you take care of them. Still, some sensors need to be replaced after heavy use or tough conditions. People keep extra sensors ready for quick swaps. They also track how long each sensor lasts to plan for the future.

Note: Many people say, “A little care helps a lot. Regular checks help sensors last longer.”

User Tips and Recommendations

Installation Best Practices

Many users say a good installation makes a big difference. They often follow a few simple steps to get the best results. First, they check the sensor and the surface for dirt or dust. Clean surfaces help sensors stick better and give steady readings. Next, they use the right adhesive or mounting tape. Some people use double-sided tape, while others pick a special glue made for electronics. They press the sensor down gently to avoid bending or breaking it.

People also suggest testing the sensor before using it in a project. They connect it to a simple circuit and check if it responds to touch or pressure. If the sensor works, they finish the setup. If not, they try a new sensor or check the wires. Many users keep wires short and neat to stop noise or errors. They also label the wires to make future repairs easier.

Tip: Always read the sensor’s manual before starting. It can save time and prevent mistakes.

Maximizing Sensor Life

Users want their sensors to last as long as possible. They share a few key habits that help:

- Use sensors made with strong materials like self-healing polymers or composite structures. These materials help sensors last through many uses.

- Add protective coatings or covers. This keeps out water, dust, and chemicals.

- Try to keep sensors away from sharp bends or heavy pressure. Gentle handling helps them last longer.

- Store sensors in a dry, cool place when not in use.

- Aim for sensors that can handle 10,000 to 50,000 cycles. Many new sensors reach this level because of better materials.

Some people also check their sensors every few months. They look for cracks or changes in readings. If they find a problem, they fix it early. This stops bigger issues later.

Choosing the Right Film Pressure Sensor

Picking the right sensor can feel tricky, but users have a few tips. They look at the job first. For example, if the sensor will touch a liquid, they check if the materials match the fluid. Some users pick high nickel alloys for strong resistance to corrosion. Others use stainless steel for its strength and clean surface, especially in food or medical jobs.

Users also think about how the sensor measures pressure. They want sensors that do not drift and can sense small changes. Some people choose sensors with special designs for low or high pressure. They also look for brands that offer many types of sensors. This helps them find the best fit for each project.

- Check if the sensor’s material matches the job.

- Pick sensors that can handle the pressure range you need.

- Choose a supplier with many options and good support.

Note: Many users say asking for samples or demos helps them make the best choice.

Finding Reliable Reviews

People want to know if a film pressure sensor works before they buy it. They look for reviews from real users. These reviews help them see what works and what does not. Some people trust forums. Others check video guides. Many users say that reading reviews saves time and money.

Where do users find good reviews?

- Online Forums:

Users visit forums like EEVblog, Reddit’s r/AskElectronics, and All About Circuits. People share stories about sensors. They talk about what worked in their projects. Some users post pictures and test results. Others answer questions from new buyers. - Video Platforms:

YouTube has many sensor reviews. People show how they install and test sensors. Viewers see the sensor in action. Some reviewers compare brands side by side. They point out what they like and what they do not. - Product Pages:

Many brands have review sections on their websites. Buyers leave ratings and short comments. Some users write about how long the sensor lasted. Others mention if the sensor fit their project. - Tech Blogs:

Blogs like Hackaday and Adafruit share guides and reviews. Writers test sensors in real projects. They explain what happened step by step. Readers learn from their mistakes and wins.

What makes a review reliable?

| Review Feature | Why It Matters |

|---|---|

| Real User Photos | Shows the sensor in a real project |

| Test Data | Gives numbers, not just opinions |

| Long-Term Feedback | Tells if the sensor lasted |

| Clear Language | Easy to read and understand |

| Answers to Questions | Helps new buyers |

Tip: Users say to look for reviews with test results. These reviews show how the sensor works over time.

How do users spot fake or weak reviews?

- Some reviews sound too good. They use lots of praise but give no details.

- Fake reviews often repeat the same words.

- Weak reviews skip test results or real photos.

- Some users check if the reviewer posted about other products.

People trust reviews that show both good and bad points. They want to see how the sensor worked in real life. Many users say that reading three or more reviews helps them make better choices.

How do users use reviews to pick a sensor?

- They write down what matters most for their project.

- They compare notes from different reviews.

- Some users ask questions in the comments. Reviewers often reply with more tips.

Note: Many users say that reviews from engineers and teachers help the most. These reviews use simple words and show clear results.

People who read reviews feel ready to choose the right film pressure sensor. They know what to expect. They avoid common mistakes. Reliable reviews make buying easier for everyone.

People in 2025 trust SOUSHINE and other top brands for their film pressure sensor needs. Buyers look for reliability, accuracy, easy setup, strong build, and good value. They read reviews and follow tips from other users. Smart shoppers compare options and ask questions before buying. Want the best results? Check user stories and pick a sensor that fits your project.

FAQ

What is a film pressure sensor?

A film pressure sensor measures force or pressure when someone presses on it. The sensor changes its electrical resistance. Devices read this change and show how much force someone uses.

Where do people use film pressure sensors?

People use these sensors in cars, medical tools, sports gear, and robots. They help track pressure, improve safety, and make devices smarter.

How do you install a film pressure sensor?

Most users clean the surface first. They stick the sensor down with tape or glue. Then, they connect wires to a circuit or device. Testing comes last.

How long do film pressure sensors last?

Many sensors work for thousands of uses. Some last longer if users handle them gently and keep them clean. Checking sensors often helps them last.

Can film pressure sensors get wet?

Some sensors resist water. Others do not. Users should check the product details. If the sensor is not waterproof, they keep it dry for best results.

How do you pick the right sensor?

Users look at what they need. They check the size, shape, and pressure range. They also read reviews and ask for help if needed.

Are film pressure sensors expensive?

Prices change by brand and features. Some cost less for simple jobs. Others cost more for special uses. Many users say good sensors save money over time.