Call us: +86-137-2353-4866

A force sensor checks mechanical force and changes it to an electrical signal. People use force sensors every day, but they may not notice. For example, touch buttons on phones or elevators use them to feel pressure. Knowing how a force sensor works helps people pick the right tool in healthcare and robotics. SOUSHINE is a leader with its advanced Force Sensing Resistors (FSRs). These sensors have many types, are cost-effective, and are wanted more in cars and healthcare.

| Aspect | SOUSHINE FSRs | Other Force Sensor Technologies |

|---|---|---|

| Market Leadership | Yes | Varies |

| Cost-Effectiveness | High | Varies |

| Industry Demand | Growing in cars, healthcare, etc. | Varies |

| Product Variety | Many types available | Limited options |

Table of Contents

Key Takeaways

- Force sensors change mechanical force into electrical signals. These sensors are important in things like touch buttons and elevators.

- SOUSHINE’s Force Sensing Resistors (FSRs) are accurate and last a long time. They also use little power, so they work well in many situations.

- There are different types of force sensors. Some are strain gauges, piezoelectric sensors, and capacitive sensors. Each type is good for certain jobs because of how sensitive and strong they are.

- Knowing about units like newtons and pounds helps engineers pick the right sensor. This is important for their projects.

- Force sensors are very important in cars, hospitals, and robots. They help make things safer and work better.

- When you pick a force sensor, think about how strong and sensitive it is. Also, think about where it will be used to make sure it works well.

- SOUSHINE has FSRs that can be changed to fit different needs. Engineers can pick the size and shape they want for their projects.

- In the future, force sensors will use smart technology and connect to the Internet of Things. This will help devices work faster and better.

Force Sensor Measurement Principle

Mechanical to Electrical Conversion

A force sensor works by using a simple idea. It finds mechanical force and turns it into an electrical signal. This helps people know how much force is in a system. Different devices use different ways to measure force. Some common ways are:

- Strain gauge load cells find force by sensing strain with a Wheatstone bridge circuit.

- Piezoelectric sensors use stress to make an electrical charge. This charge shows the force amount.

- Force Sensing Resistors (FSRs) from SOUSHINE change resistance when force is put on them. The sensor has layers that touch when pressed. This lets electricity move through. The change in resistance gives a clear signal about the force.

A force sensor can check two main types of force: tension and compression. Tension means pulling or stretching. Compression means pushing or squeezing. The way these forces are measured is not the same. The table below shows the main differences:

| Feature | Tension Load Cells | Compression Load Cells |

|---|---|---|

| Direction of Force | Measures pulling or stretching forces | Measures pushing or compressing forces |

| Structure | Rod or beam-like | Cylindrical or pancake-shaped |

| Sensitivity | More sensitive to external factors | More rugged and durable |

| Calibration | Can be calibrated for tension only or both | Often calibrated for high-capacity compressive loads |

| Common Applications | Crane scales, tensile testing | Weighbridges, platform scales |

A force transducer changes force into a signal people can read. This signal helps engineers and scientists know how much force is there. The way each sensor works makes it good for different jobs.

Units of Measurement

Units help people know how much force a sensor finds. Force sensors use different units to show force. The most common units are:

- Newtons

- Kilograms

- Pounds

Engineers choose the unit based on what they need. For example, newtons are used in science labs. Kilograms are used in weighing systems. Pounds are used in many factories. These units help people compare results from different devices.

How a transducer shows force in these units depends on how it works. The unit picked depends on what the user wants. SOUSHINE makes its sensors work with all main units. This makes them useful for many jobs.

How sensors work, their design, and the unit picked all matter. They help users get correct results in many areas.

Types of Force Sensors

Strain Gage Sensors

A strain gauge force sensor is very common. It has a thin wire or foil on a flexible base. When force pushes or pulls, the wire stretches or squeezes. This changes the electrical resistance in the circuit. Engineers call this device a load cell. Load cells with strain gauges can check both tension and compression.

Strain gauge sensors are very accurate and sensitive. Many industries use them for exact measurements. But things like temperature or humidity can change how well they work. These sensors are found in weighing scales, machines, and lab tools.

Key points about strain gauge sensors:

- Very accurate and sensitive

- Can check tension and compression

- Used in load cell designs for many jobs

- Sensitive to changes in the environment

Piezoelectric Sensors

Piezoelectric sensors are also important types of force sensors. These sensors use special materials that make electric charge when squeezed or stretched. The sensor turns this charge into a signal people can read. A piezoelectric force sensor does not need extra power to make a signal.

Piezoelectric sensors work well for fast force changes. They can measure quick vibrations or impacts. Many industries use them for checking quality, controlling processes, and medical devices. They are also used in aerospace, nuclear tools, and electronics. For example, engineers use them to watch engine combustion or measure turbulence.

Piezoelectric sensors are strong and can handle tough places. They are great for measuring fast compression or tension. But they may not work as well with slow or steady forces.

Common uses for piezoelectric sensors:

- Checking quality and controlling processes

- Medical and aerospace jobs

- Measuring fast forces and vibrations

- Watching engine combustion

Comparison of strain gage and piezoelectric sensors:

| Feature | Strain Gage Sensors | Piezoelectric Sensors |

|---|---|---|

| Sensitivity | High | High for fast forces |

| Durability | Can be changed by environment | Strong in tough places |

| Best Use | Exact, steady forces | Fast, changing forces |

Capacitive Sensors

Capacitive sensors are another type of force sensor. A capacitive force sensor checks force by finding changes in capacitance. When force presses on the sensor, it bends a material inside. This changes the space between two plates, which changes the capacitance.

Capacitive sensors can be very precise. They use special materials and smart signals to give good results. Many engineers use them in touch screens, robots, and medical tools. But these sensors can be changed by things like temperature and humidity. They also have a small force range and can cost more because of their complex parts.

Main features of capacitive sensors:

- Check force by finding changes in capacitance

- Very precise in measurement

- Sensitive to things in the environment

- Small force range and higher price

The load cell, piezoelectric force sensor, and capacitive force sensor each help with different jobs. The best choice depends on what you need and the type of force you want to measure.

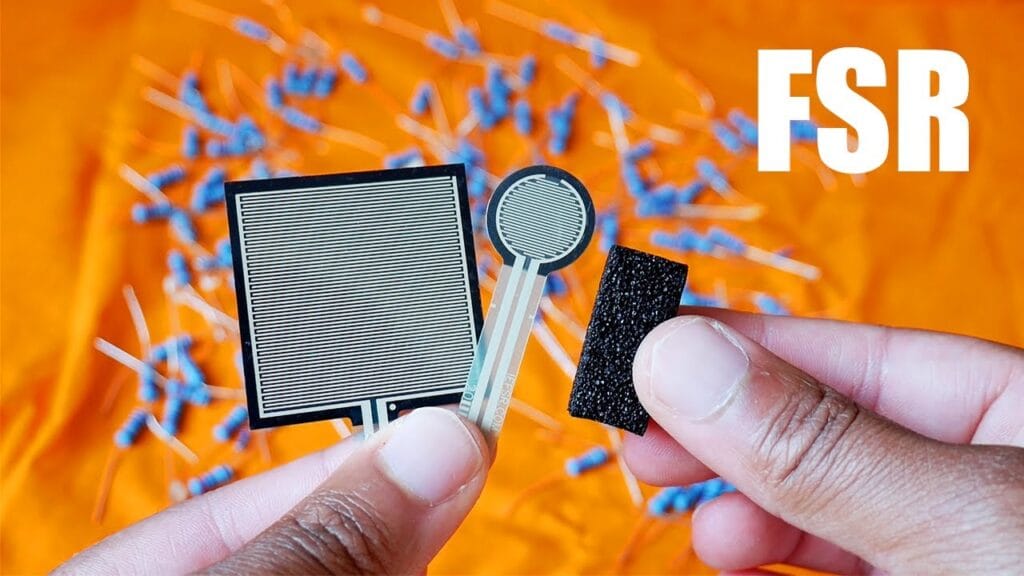

Force Sensing Resistors (FSRs)

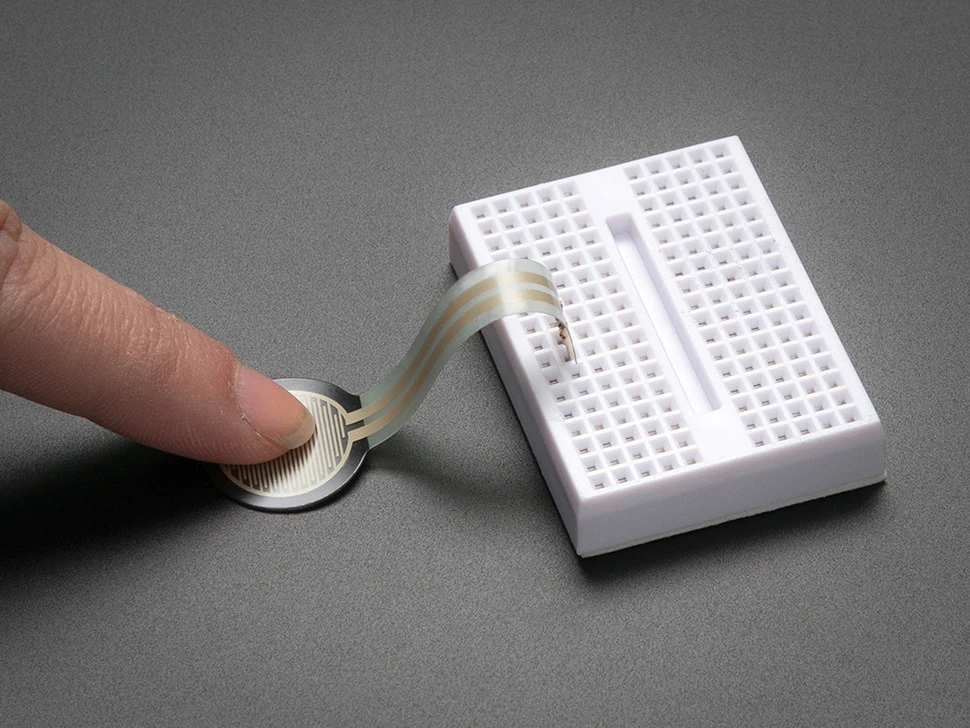

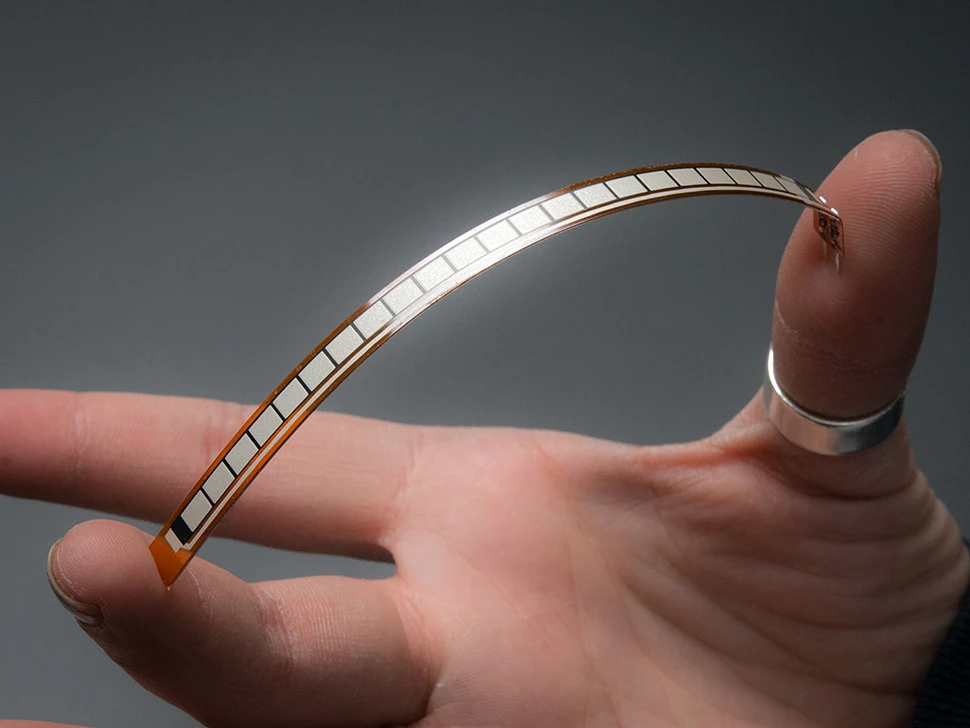

A Force Sensing Resistor checks force by changing resistance. When you press the sensor, resistance goes down. The sensor has a bendable part and a layer that conducts electricity. Pressure pushes these layers together so electricity can move. More force means more electricity flows through the sensor. FSRs send a steady signal, not just on or off. This lets engineers watch force as it happens.

FSRs work in lots of devices. You can find them in touch buttons, medical tools, and robots. The sensor reacts fast when pressure changes. It does not need much power, so it is good for things you carry. FSRs come in many shapes and sizes. Designers can use them in many products.

SOUSHINE FSR Features

SOUSHINE makes Force Sensing Resistors that are advanced. These sensors are special for a few reasons. The company gives sensors that are very accurate and tough. SOUSHINE lets people pick from many choices. Their FSRs use little power and are simple to add to new things.

SOUSHINE helps engineers with flexible answers. The sensors work in cars, healthcare, and robots. The team helps customers pick the best sensor for each job.

The table below shows how SOUSHINE’s FSRs compare to other brands:

| Feature | SOUSHINE’s FSRs | Competitors’ FSRs |

|---|---|---|

| Accuracy | Superior | Varies |

| Durability | High | Moderate |

| Customization | Extensive | Limited |

| Low Power Consumption | Yes | Varies |

| Ease of Integration | Simple | Complex |

- SOUSHINE’s FSRs work for many needs.

- The sensors last a long time, even in hard places.

- Customers can choose the shape and size they want.

- The sensors use less energy, so they save power.

SOUSHINE’s Force Sensing Resistors help engineers make better products. The sensors work in many areas and give results people can trust.

Applications of Force Sensors

Automotive

Car engineers use force sensors to make cars safer and more comfortable. These sensors check if someone is sitting in the seat. They also help control when airbags should open. Force sensors watch how hard a driver pushes the brake pedal. This helps the car know how much braking is needed. It keeps people safe by making sure brakes work right. SOUSHINE’s Force Sensing Resistors are good for cars. They react fast and last a long time.

Healthcare

Doctors and nurses use force sensors in medical tools. These sensors help them watch important health signs. The table below shows how force sensors help in healthcare.

| Application Area | Description |

|---|---|

| Pulse wave and muscle softness detection | Checks signals from pulse and muscles. |

| ICP and IOP measurement | Measures pressure inside the head or eyes. |

| Throat and cardiac activity monitoring | Watches throat and heart activity with force sensing. |

| Abdomen and pulse diagnoses | Helps find health problems in the belly or pulse. |

| Orthotics and orthodontics | Supports special devices for bones or teeth. |

| Skin-prosthesis interface | Makes feedback better between skin and fake body parts. |

New flexible force sensors are now more sensitive and work better. They let doctors see patient health right away. This means doctors do not have to wait for results. These sensors also help with tests that do not need surgery. Smart medical devices use force sensors to give care and keep patients safe. SOUSHINE’s Force Sensing Resistors are great for these jobs. They give correct data and fit many medical tools.

Robotics

Robots use force sensors to feel things like people do. These sensors help robots hold objects gently and do careful work. Robots use force sensors to press just enough when building things. This stops them from breaking soft items. Force sensors also help robots know if they bump into something. If a robot feels a strong force, it can stop or move away. This keeps people and robots safe. SOUSHINE’s Force Sensing Resistors help robots do careful jobs and make factories safer.

Tip: Force sensors help robots work with both hard and soft things. They make robots smarter and safer.

Force sensors help cars, hospitals, and robots work better. SOUSHINE’s Force Sensing Resistors give strong and flexible answers for many jobs.

Consumer Electronics

Force sensors are important in many electronics people use. These sensors help devices react to touch and movement. People use them in phones, game controllers, and wearables every day. Smartphones have touchscreens that feel how hard you press. The phone can vibrate when you press a button. Phones use force sensors for haptic feedback. When you tap or swipe, the phone buzzes gently. Game controllers use force sensors to make games more exciting. The controller can vibrate or push back. This makes games feel more real. Fitness trackers use force sensors to watch movement. They count steps and measure how hard you press. They give feedback right away. VR systems use controllers with force sensors. These controllers help you feel like you touch things in a game. Smart clothing uses force sensors to check posture and movement. This helps people exercise better and watch their health. SOUSHINE’s Force Sensing Resistors work well in these devices. They are thin and bend easily, so they fit in small spaces. The sensors use little power, so devices last longer. SOUSHINE FSRs help make devices give fast and correct feedback.

More people want better user experiences. This makes force sensors more popular in electronics. As smart devices grow, people need sensors they can trust.

Industrial Automation

Factories use force sensors to help machines work well. These sensors check quality, control machines, and keep workers safe. The table below shows some common uses and their benefits:

| Application Area | Benefits |

|---|---|

| Automotive Manufacturing | Checks force on clamps for quality |

| Aerospace | Tests loads on parts for safety |

| Food Processing | Checks weight for product quality |

| Medical Devices | Ensures precision in device making |

| Construction | Studies load on structures for safety |

Force sensors give feedback right away. This helps machines work better and faster. They also help stop problems before they start. SOUSHINE FSRs are strong and use little power. This makes them good for busy factories.

Force sensors help keep products safe and machines working well in many industries.

Aerospace

Aerospace companies use force sensors to check planes and spacecraft. These sensors look for cracks, stress, and other problems in parts.

Dennis Roach, a scientist at Sandia National Laboratories, says, “Our work shows the sensors are safe and reliable for aircraft maintenance.”

Delta Air Lines and other plane makers use many sensors. These sensors watch for problems during flights. Some sensors, like CVM sensors, find cracks by checking small galleries. Other sensors, like piezoelectric sensors, use sound waves to find damage.

- CVM sensors help find cracks by watching special galleries.

- Piezoelectric sensors use sound waves to find damage.

SOUSHINE FSRs can help with these jobs. Their flexible design lets engineers put them in tight spaces. The sensors give quick feedback to help keep planes safe.

How Force Sensors Work

Sensor Construction

Force sensors have different parts inside to measure force. Each sensor type works in its own way. But most sensors have some main parts. The table below lists these important parts:

| Component | Description |

|---|---|

| Flexible Substrate | Made from things like polymer or elastomer, it is the base of the sensor. |

| Conductive Materials | Uses carbon or special ink to make a path for electricity. |

| Strain Gauges | Finds bending from force and changes resistance to show force. |

| Wheatstone Bridge Circuit | Measures resistance changes and turns them into voltage to show force. |

A flexible substrate is the bottom layer. When you push on it, the base bends or stretches. Conductive materials, like carbon or ink, let electricity move across the sensor. Strain gauges are often zigzag shapes on the base. When the sensor bends, the strain gauge stretches or gets squeezed. This changes the resistance in the circuit. The Wheatstone bridge circuit checks this change and makes a voltage signal.

SOUSHINE’s Force Sensing Resistors use a flexible base and a layer that conducts electricity. When you press the FSR, the layers touch and let electricity flow. The resistance goes down as you press harder. This setup gives a steady signal that matches the force. SOUSHINE FSRs come in many shapes and sizes. This makes them easy to use in many products.

Note: The flexible base and conductive layers in SOUSHINE FSRs help the sensor last longer and work in many places.

Signal Processing

After the sensor feels force, the signal needs to be fixed. The first signals from force sensors can be noisy or weak. Signal processing makes the data better and more reliable.

- Filtering takes away noise and extra signals.

- Averaging many readings makes the results more steady.

- Amplification makes weak signals stronger and easier to read.

Modern systems use smart tools, like machine learning, to remove noise and fix problems right away. This makes the data more correct. Good signal processing is important for all force sensors, even SOUSHINE FSRs. It helps engineers trust the numbers they get.

SOUSHINE FSRs work well with these signal processing steps. The sensors give a clear signal that is easy to use. This helps in many jobs, like cars and medical tools.

Tip: Good signal processing means better results and safer products.

Advantages and Limitations

Accuracy

Accuracy means how close a sensor’s reading is to the real force. If a sensor is accurate, its number is almost the same as the true force. The datasheet tells you the accuracy class. This class shows the biggest error as a percent. For example, a 1% accuracy class means the reading is never more than 1% off. Sensors with better accuracy can find tiny changes in force. This is important in labs or when checking quality.

- Accuracy is about how close the reading is to the real force.

- High accuracy helps engineers believe the data.

- SOUSHINE FSRs give steady readings for many jobs.

Note: Always look at the accuracy class in the datasheet before picking a sensor for important work.

Sensitivity

Sensitivity means how well a sensor feels small changes in force. Some sensors can notice tiny changes. Others need more force to react. The table below shows how different sensors compare in sensitivity:

| Type of Force Sensor | Sensitivity Characteristics |

|---|---|

| Strain Gauges | Give steady results and measure changes in resistance when bent or stretched. |

| Piezoelectric Force Sensors | Respond quickly and accurately to force, with a linear response up to part of their range. |

| Capacitive Force Sensors | React fast, with short settling and recovery times, and work well over many cycles. |

| Force Sensing Resistors (FSRs) | Change resistance under pressure, fit many shapes and sizes, and work in new designs. |

SOUSHINE FSRs can fit many shapes and sizes. They work well in things that need to feel touch or pressure. Their design lets them sense both soft and hard pushes.

Tip: Choose a sensor with the right sensitivity for your job. High sensitivity is good for jobs that need to find small changes.

Durability

Durability means how long a sensor keeps working after many uses. In factories and other hard places, sensors must last through lots of pressing. Some sensors, like FlexiForce, have worked after one million presses in tough tests. After 10,000 uses, tests check if the sensor still works right.

- Many force sensors last for thousands or millions of uses.

- SOUSHINE FSRs are built strong. They keep working in busy places like factories, cars, and hospitals.

- Long-lasting sensors save money and time because you do not need to change them often.

SOUSHINE FSRs are known for being tough. They keep working well, even after lots of use in hard jobs.

Power Consumption

Power consumption is important when picking a force sensor. Devices that use less power can last longer on batteries. This is helpful for portable products and things that must save energy.

Different force sensors use different amounts of power. Some sensors need more energy to work. Others use very little power. The table below shows how much power each type uses:

| Sensor Type | Power Consumption | Typical Use Case |

|---|---|---|

| Strain Gage Sensors | Moderate to High | Industrial scales, machines |

| Piezoelectric Sensors | Very Low (for sensing) | Vibration, impact detection |

| Capacitive Sensors | Low to Moderate | Touchscreens, medical devices |

| Force Sensing Resistors (FSRs) | Very Low | Wearables, portable electronics |

Strain gage sensors need a steady power supply. They use circuits to check small resistance changes. These circuits can use more energy, especially in big systems.

Piezoelectric sensors make their own signal when pressed. They do not need extra power to sense force. But some systems use power to handle the signal or save data.

Capacitive sensors use a small amount of power. They check for changes in capacitance when force is used. Some designs use more energy if they need fast or many readings.

Force Sensing Resistors (FSRs) use very little power. These sensors only use current when someone presses them. When there is no force, the circuit uses almost no energy. This makes FSRs a good pick for battery-powered devices.

SOUSHINE FSRs help designers make products that last longer on one charge. Many wearables, smart gadgets, and portable medical tools use SOUSHINE FSRs for this reason. The sensors fit well in systems that must save energy.

Tip: Low power sensors help devices last longer and stay cool. This can make products safer and more reliable.

Engineers often choose SOUSHINE FSRs for projects where saving power matters. The sensors work well in both small and big devices. They help cut down on battery changes or recharging.

Choosing a Force Sensor

Application Needs

Picking the right force sensor starts with knowing the job. Every project needs something different. Some sensors are tough for hard jobs. Others are small for tiny spaces. The table below shows what to think about:

| Factor | Description |

|---|---|

| Durability | The sensor must handle strains and rough use. FSRs are strong in harsh conditions. |

| Environment | The place where the sensor works affects accuracy. FSRs resist dust and moisture. |

| Form Factor | The size and shape matter. FSRs fit small or flexible designs. |

| Repeatability | Sensors should give the same result each time. Reliable sensors help in production. |

| Sensitivity | The sensor must detect the right range of forces. New FSRs sense a wide range. |

| Cost | The sensor should match the budget and needs. Sometimes a simple sensor is enough. |

Tip: Write down what your project needs before you choose. This helps you avoid mistakes later.

Sensor Comparison

Each sensor type is good at something special. Strain gauge sensors are best for steady forces. Piezoelectric sensors are fast for quick changes. Capacitive sensors work well in touch screens and medical tools. FSRs from SOUSHINE are flexible and use little power. They come in many shapes and sizes.

| Sensor Type | Best Use | Key Feature |

|---|---|---|

| Strain Gauge | Weighing, steady force | High accuracy |

| Piezoelectric | Vibration, fast force changes | Quick response |

| Capacitive | Touch, medical devices | Precise, sensitive |

| FSR (SOUSHINE) | Wearables, robotics, cars | Flexible, low power, durable |

The best sensor depends on what matters most for your job. Some projects need very accurate sensors. Others need sensors that fit in small places or last a long time.

SOUSHINE Customization

SOUSHINE lets you pick from many sensor choices. You can get different sizes, shapes, and sensitivity levels. This helps car makers and other companies use sensors in many products. They do not have to change their designs. SOUSHINE makes it easy to add sensors to new or old systems. Most other brands do not give this many choices. SOUSHINE also helps customers from start to finish. Their team helps you pick the best sensor for your job.

SOUSHINE’s help and many options make it easier for engineers to fix problems and make better products.

Future Trends

Smart Sensors

Smart sensors are changing how people use force sensors. New designs now have 6-axis force torque sensors. These sensors can measure force and torque in three ways at once. Robots and machines can react with better control. In healthcare, smart sensors help prosthetics move more naturally. Surgical robots use them for smoother actions. Fitness devices use these sensors to track movement and force. Smartwatches and VR systems use force sensors to make devices more fun.

- Smart shoes use force sensors to check walking pressure.

- Prosthetics use force sensors for smoother movement.

- Surgical robots use force sensors for better feedback.

Smart sensors help devices give better feedback and make users happier.

IoT Integration

The Internet of Things (IoT) links force sensors to networks. This lets devices share data right away. In factories, force sensors help machines work better and safer. Wireless load cells make it easy to get data without lots of wires. Smart floors use force sensors to watch movement and pressure. These floors collect data and help manage spaces.

| Application Type | Description |

|---|---|

| Industrial | Force sensors watch and control machines in smart factories. |

| Consumer | Wearables and VR use force sensors for quick feedback. |

| Smart Floors | Built-in sensors collect movement and pressure data. |

| Wireless Load Cells | Make data collection easy and cut down on wires. |

| Self-Optimizing Factories | Use quick data to improve quality and save money. |

IoT helps force sensors send data fast and makes devices smarter.

New Applications

Force sensors are now used in many new places. Industrial robots use them to work faster and safer. Car makers use force sensors in electric cars and for automation. Wearables and smart devices use force sensors to track movement and touch. IoT and Industry 4.0 use force sensors for quick monitoring and data checks.

- Car makers focus on automation and electric cars.

- Industrial robots use force sensors for better control.

- Wearables and smart devices use force sensors for new features.

The force sensor market is getting bigger. Experts think it will reach $3.08 billion by 2029. Growth comes from IoT, robots, and new flexible sensors. Wireless connections and quick data processing are big trends. Gaming, VR, and AR use more force sensors every year.

The future of force sensors will have smaller sizes, smarter features, and more uses in everyday life.

A force sensor finds mechanical force and gives back helpful information. Picking the right force sensor helps people fix problems in many areas. SOUSHINE is a top company because it makes good products and new ideas. The company checks every part of making sensors and gives custom choices.

| Step | Description |

|---|---|

| 1 | Begin with a thin bottom layer |

| 2 | Put on a printed layer that carries electricity |

| 3 | Add a sticky or bonding layer |

| 4 | End with a top cover layer |

- SOUSHINE checks materials and sensors to make sure they work well.

- Special designs help with unique needs.

Force sensors will help create new inventions and better technology soon.

FAQ

What does a force sensor measure?

A force sensor checks mechanical force. It turns force into an electrical signal. This helps people see how much force is in a system.

Where do people use force sensors?

People use force sensors in cars and robots. They are also in medical devices and electronics. Factories and aerospace companies use them for safety and quality.

How does a Force Sensing Resistor (FSR) work?

An FSR changes resistance when you press it. The sensor has layers that touch when pressed. This lets electricity move and shows the force.

Why do engineers choose SOUSHINE FSRs?

Engineers pick SOUSHINE FSRs because they are tough. They use little power and have a flexible design. These sensors fit many products and last long.

What units do force sensors use?

Force sensors use newtons, kilograms, or pounds. The unit depends on the job and the system.

Can force sensors work in wet or dusty places?

Many force sensors, like SOUSHINE FSRs, work in wet or dusty places. Their design helps them block moisture and dirt.

How long does a force sensor last?

A force sensor can last for thousands or millions of uses. SOUSHINE FSRs keep working in busy places like factories and hospitals.

Do force sensors need much power?

Most force sensors use very little power. SOUSHINE FSRs help devices save energy and last longer on batteries.