Call us: +86-137-2353-4866

In the world of modern electronics, Force Sensitive Resistors (FSRs) have become essential components in a wide range of applications—from robotics and medical devices to smart wearables and touch panels. These compact, flexible sensors detect changes in pressure, force, or weight, converting mechanical input into measurable electrical signals.

As a professional manufacturer and designer of custom FSR sensors, SOUSHINE provides tailored sensing solutions for global clients seeking accuracy, durability, and cost-effective performance.

Table of Contents

What Is a Force Sensitive Resistor (FSR)?

A Force Sensitive Resistor, or FSR, is a thin, flexible sensor whose electrical resistance changes in response to applied pressure or force.

When you press on the sensor surface, the resistance decreases—creating a measurable change in voltage that can be detected by a circuit.

Unlike rigid load cells or complex capacitive sensors, FSRs are lightweight, ultra-thin, and inexpensive to produce, making them ideal for compact and flexible electronic systems.

Key Features:

- Detects force or pressure through resistance change

- Simple structure and easy integration

- Suitable for flat or curved surfaces

- Excellent for wearable and touch-based interfaces

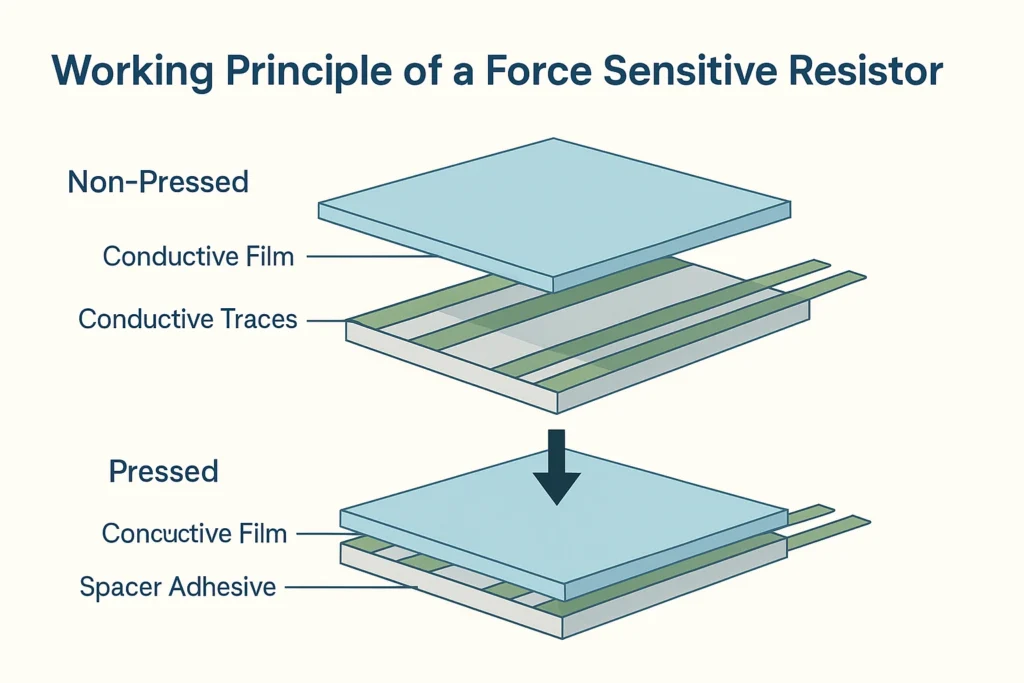

Working Principle of a Force Sensitive Resistor

At the heart of every FSR is a simple principle: resistance decreases as applied force increases.

When no force is applied, the conductive particles inside the sensor are loosely distributed, resulting in high resistance. Once pressure is applied, these particles come into closer contact, forming more conductive pathways—therefore reducing resistance.

This behavior follows Ohm’s Law, where the voltage output is inversely proportional to resistance, and thus directly related to the applied force.

Typical Force-Resistance Behavior:

- No force → high resistance (around 1MΩ or higher)

- Moderate force → resistance drops significantly (10kΩ–100kΩ)

- Heavy force → resistance can fall below 1kΩ

This simple yet effective principle enables FSRs to be used in countless applications requiring pressure, touch, or weight detection.

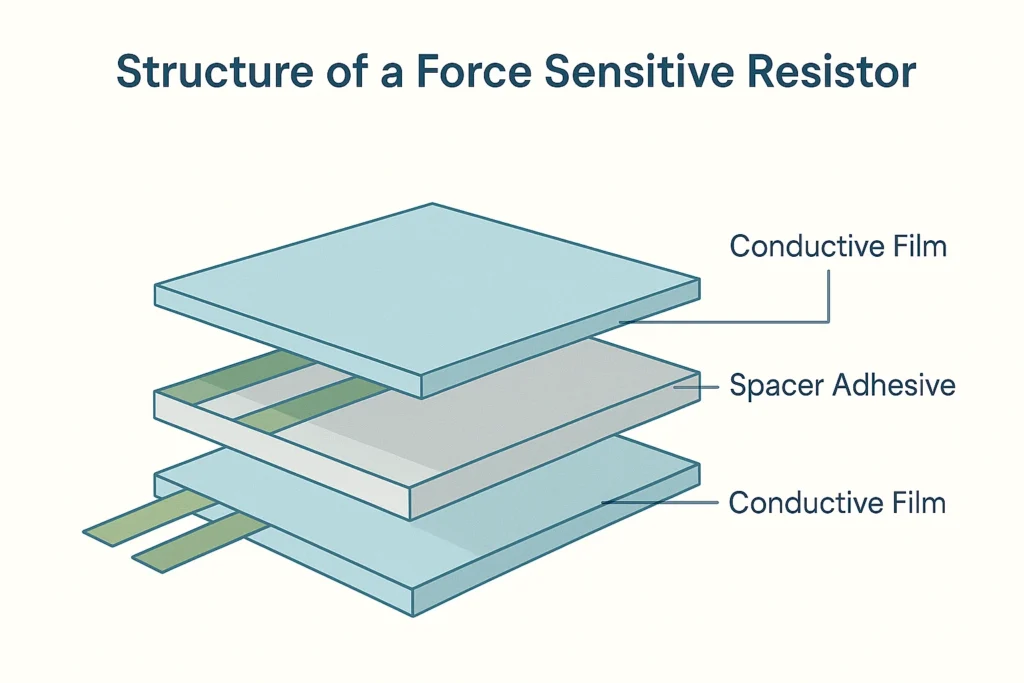

Structure and Materials

A standard FSR sensor consists of multiple thin layers laminated together:

- Substrate Layer (PET film): Provides flexible support.

- Conductive Traces: Printed using silver or carbon ink.

- Spacer Adhesive: Creates a small air gap to ensure separation when no force is applied.

- Active Layer: Contains a semi-conductive polymer film with carbon particles.

- Protective Overlay: Ensures durability and environmental resistance.

When pressure is applied, the conductive particles on the active layer bridge the gap between the traces, forming an electrical connection that reduces resistance.

At SOUSHINE, we customize each FSR’s size, shape, sensitivity, and connector type according to the customer’s design requirements. This ensures perfect integration into various devices and applications.

Electrical Characteristics and Performance

The performance of a Force Sensitive Resistor depends on its materials, thickness, and electrode design. Below are some typical specifications for SOUSHINE’s custom FSR sensors:

| Parameter | Typical Range |

|---|---|

| Force Range | 0.1N – 10N (customizable up to 100N) |

| Resistance (No Load) | >1MΩ |

| Resistance (Full Load) | <1kΩ |

| Repeatability | ±10% |

| Response Time | <5ms |

| Durability | >1 million actuations |

| Operating Temperature | -30°C to +85°C |

Each sensor is tested to ensure high repeatability and minimal drift, following ISO9001-certified manufacturing standards.

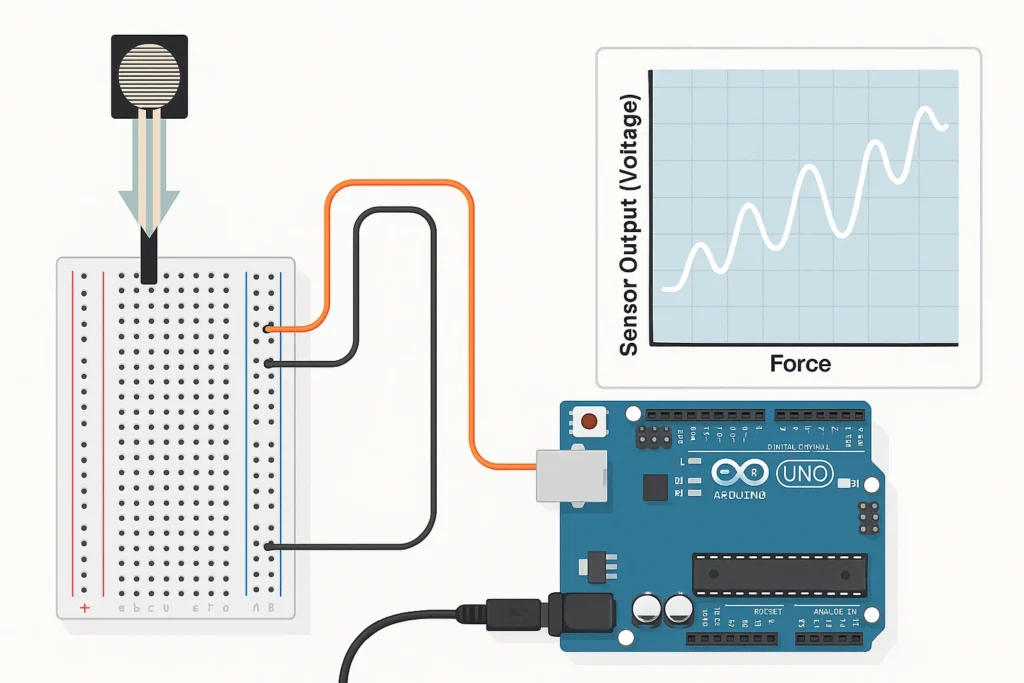

Circuit Integration and Signal Measurement

Integrating an FSR into a circuit is straightforward. The most common method uses a voltage divider configuration, where the FSR forms one leg of a resistor pair.

When force is applied, the resistance of the FSR changes, altering the output voltage, which can then be read by a microcontroller (Arduino, Raspberry Pi, or PLC).

Example Arduino Circuit:

const int FSR_PIN = A0;

int fsrReading = 0;

void setup() {

Serial.begin(9600);

}

void loop() {

fsrReading = analogRead(FSR_PIN);

Serial.println(fsrReading);

delay(100);

}

This simple setup enables engineers to measure relative pressure and create interactive prototypes rapidly.

Applications of Force Sensitive Resistors

FSRs are extremely versatile and can be found in nearly every field that requires tactile or pressure sensing. Below are the most common industries and their typical use cases:

1️⃣ Robotics and Automation

- Gripper feedback systems

- Collision detection sensors

- Tactile sensing in robotic hands

2️⃣ Medical Devices

- Prosthetic feedback sensors

- Bed pressure monitoring systems

- Force mapping in rehabilitation equipment

3️⃣ Wearable Technology

- Smart shoes and insoles

- Pressure-sensitive gloves

- Sports performance trackers

4️⃣ Industrial Control

- Equipment pressure monitoring

- Assembly line feedback

- Operator safety panels

5️⃣ Consumer Electronics

- Gaming controllers and musical instruments

- Touch-sensitive buttons and keypads

- Smart home appliances

Each of these applications benefits from the FSR’s thin profile, flexibility, and durability, allowing seamless integration into both rigid and flexible systems.

Advantages of Force Sensitive Resistors

The popularity of FSRs continues to grow due to their balance of performance, flexibility, and cost. Key advantages include:

- Compact and Lightweight: Ideal for portable and wearable devices.

- Flexible Design: Easily fits curved or irregular surfaces.

- Low Power Consumption: Suitable for battery-powered applications.

- Durable and Reliable: Millions of actuations with minimal wear.

- Simple Interface: Easy to read using analog circuits or microcontrollers.

- Affordable: Cost-effective alternative to complex load cells or capacitive sensors.

At SOUSHINE, these advantages are further enhanced through customization—from unique shapes to adjustable sensitivity curves.

Why Choose SOUSHINE as Your FSR Manufacturer

With over 20 years of expertise in sensor manufacturing, SOUSHINE has become a trusted global partner in the design and production of Force Sensitive Resistors.

We provide:

- Fully customized FSR solutions (size, force range, connector type)

- Fast prototyping and global delivery

- In-house R&D and testing laboratories

- Strict ISO9001 quality control system

- OEM/ODM support for industry clients

Whether you’re developing a new smart device or upgrading your existing product line, our engineers can provide professional consultation and manufacturing services to match your exact requirements.

Get in touch today:

Contact SOUSHINE to discuss your project or request a free consultation.

Conclusion

The Force Sensitive Resistor (FSR) is a versatile and reliable solution for detecting pressure, force, or touch. Its thin and flexible design allows it to fit seamlessly into modern devices, offering engineers a practical balance between cost and performance.

From initial design to mass production, SOUSHINE delivers custom FSR solutions that meet global standards of precision, consistency, and durability—helping businesses integrate smarter sensing into every product.