Call us: +86-137-2353-4866

A tactile membrane switch is a type of membrane switch that gives users a clear physical response, such as a noticeable snap or click, when pressed. This feedback helps users know their input registered, which is important in situations where visual or sound cues may not be available. For example, SOUSHINE designs its switches so users can feel each press, increasing accuracy and confidence, especially in medical and industrial settings.

Table of Contents

Key Takeaways

- Tactile membrane switches provide clear feedback, helping users know their input registered.

- These switches are durable, lasting between 5 to 10 million keystrokes, making them ideal for frequent use.

- The layered design of tactile membrane switches includes a graphic overlay, circuit layer, and tactile layer for reliable performance.

- Customization options allow for unique graphics and features like LED backlighting, enhancing user experience.

- Sealed construction protects against moisture, dust, and chemicals, ensuring longevity in harsh environments.

- Tactile feedback improves user confidence and accuracy, especially in medical and industrial applications.

- Dome switches offer a distinct snap response, while flat keypads lack tactile feedback, impacting user satisfaction.

- SOUSHINE’s advanced materials and designs meet modern interface needs across various industries, including automotive and consumer electronics.

Tactile Membrane Switch Basics

Definition

A tactile membrane switch is a user interface component that registers input when pressed and provides a physical response. This response often feels like a snap or click. The tactile membrane switch uses a layered structure to achieve this effect. Each layer has a specific function, and together they create a reliable and responsive keypad. SOUSHINE designs its tactile membrane switch keypad for accuracy and ease of use in many environments.

Key Features

A tactile membrane switch stands out because of its physical feedback and robust construction. The main physical components include:

- Graphic Overlay

- Mounting Adhesive

- Tactile Layer

- Circuit Layer

- Circuit Tail

- Back Panel

- Display Windows

- Backlighting & Indicators

SOUSHINE uses advanced materials in its membrane switch products. The table below shows common materials and their roles:

| Material | Description |

|---|---|

| Polyester (PET) | Used for flexibility and insulation. |

| Polyimide (PI) | Provides high-temperature resistance and electrical insulation. |

| Silver Ink | Used for conductive traces, offers excellent conductivity. |

| Carbon Ink | A cost-effective option for less demanding applications. |

| Stainless Steel | Gives good spring action and durability for tactile feedback. |

| Polymer Domes | Lightweight and cost-effective for tactile feedback. |

| Copper Alloy | More affordable than stainless steel, but may have a shorter lifespan. |

SOUSHINE integrates features such as LED backlighting and EMI/RFI shielding. These features improve usability and protect sensitive electronics.

How It Works

The tactile feedback mechanism in a tactile membrane switch operates through a dome structure. When a user presses a key, the plunger pushes against the dome. The dome deforms and closes the circuit by bringing the contact terminal into engagement. This action creates a noticeable snap or click, letting the user know the input registered. When the user releases the key, the dome springs back to its original shape and breaks the circuit.

A tactile switch uses this dome structure to provide reliable feedback. SOUSHINE’s membrane switch design ensures each press feels consistent. The average lifespan of a tactile membrane switch ranges from 5 to 10 million keystrokes under normal usage. This durability makes it suitable for frequent use in demanding settings.

Recent innovations in tactile membrane switch design include ESD and EMI shielding, integrated backlighting, and rapid prototyping. These advances help SOUSHINE deliver products that meet modern interface needs.

Membrane Switch Structure

A membrane switch uses a layered design to deliver reliable performance and user interaction. Each layer serves a specific function and contributes to the overall operation of the switch.

Layers

Graphic Overlay

The graphic overlay forms the top layer of the membrane switch. This layer displays the keys, symbols, and legends that guide user interaction. SOUSHINE uses polyester and specialized hard coats for the overlay. These materials resist scratches and chemicals, which helps maintain visibility and usability in demanding environments.

Spacer

The spacer separates the graphic overlay from the circuit layer. It creates a gap that prevents accidental activation of the switch. When a user presses a key, the overlay flexes and bridges this gap, allowing the circuit to close. The spacer ensures precise actuation and extends the lifespan of the switch.

Circuit

The circuit layer contains conductive traces made from silver or carbon ink. This layer enables the membrane switch to register input. When the overlay presses down, it connects the circuit, allowing current to flow and sending a signal to the device. SOUSHINE uses advanced materials and precise printing techniques to ensure consistent electrical performance.

Note:

The table below summarizes the main layers and their functions in a membrane switch.

| Layer | Function |

|---|---|

| Overlay | Provides the user interface with keys and legends, essential for visibility and usability. |

| Spacer | Separates the overlay from the printed circuit, allowing for key activation to complete the circuit. |

| Printed Circuit | Contains conductive traces that close the circuit when a key is pressed, enabling electrical flow. |

| Adhesive | Secures the switch to the product, crucial for maintaining functionality and performance. |

| Filler | Fills voided space, not functional but aids in the overall structure of the switch. |

SOUSHINE applies high-performance adhesives and waterproof materials to protect the internal layers. These techniques help prevent moisture, dust, and chemicals from entering the switch.

Tactile Feedback Mechanism

A tactile membrane switch relies on a dome-shaped contact to provide tactile feedback. When a user presses a key, the overlay flexes and pushes down on the dome. The dome collapses, closing the circuit and creating a distinct snap or click. This action signals that the input has registered. When the user releases the key, the dome returns to its original shape, breaking the circuit and resetting the switch.

The tactile switch design ensures that each press feels consistent and reliable. SOUSHINE uses advanced sealing techniques, such as frame seal gaskets and industrial closed cell foam tape, to protect the switch from environmental hazards. These methods keep the switch operational in harsh conditions and extend its service life.

Tip:

SOUSHINE conducts rigorous waterproof tests and visual inspections to ensure each membrane switch meets industry standards for durability and performance.

Tactile Membrane Switch Keypad Types

Tactile membrane switch keypads come in several types, each designed to meet specific user needs. The main categories include dome switches, flat keypads, and custom keypads. Each type offers a different experience in terms of tactile feedback and usability.

Dome Switches

Dome switches use a dome-shaped element under each key. This design creates a clear response when pressed. Dome switches require a full keypress to register input, which helps prevent accidental activation. Users feel a distinct force and hear a snap or click, making these keypads suitable for environments where feedback is important.

Metal Dome

Metal dome switches use stainless steel or nickel-plated steel domes. These switches provide a crisp snap response and strong tactile feedback. Users experience a consistent feel with every press. Metal dome switches offer high durability and long life cycles. They also provide excellent conductivity, which supports reliable performance in demanding applications.

- Metal dome switches deliver a strong tactile response.

- They last through many cycles of use.

- The metal construction ensures reliable electrical contact.

Poly Dome

Poly dome switches use polyester films to form the dome. These switches create tactile feedback through the deformation of flexible materials. Poly dome switches operate more quietly than metal domes. They offer greater flexibility, which can suit applications where noise reduction is important. However, the tactile response may feel less pronounced, and durability may be lower compared to metal domes.

- Poly dome switches provide a softer tactile response.

- They operate with less noise.

- The flexible material allows for quieter operation.

Flat Keypads

Flat keypads do not use a dome structure. They lack the snap or click found in dome switches. Users may not feel any tactile feedback when pressing these keys. Flat keypads allow for faster input but can lead to a less satisfying experience. The absence of tactile feedback may cause uncertainty about whether the input registered. These keypads often appear in devices where speed is more important than feedback.

Note: Dome switches provide tactile feedback due to their design, while flat keypads do not. This difference can impact user satisfaction and accuracy.

Custom Keypads

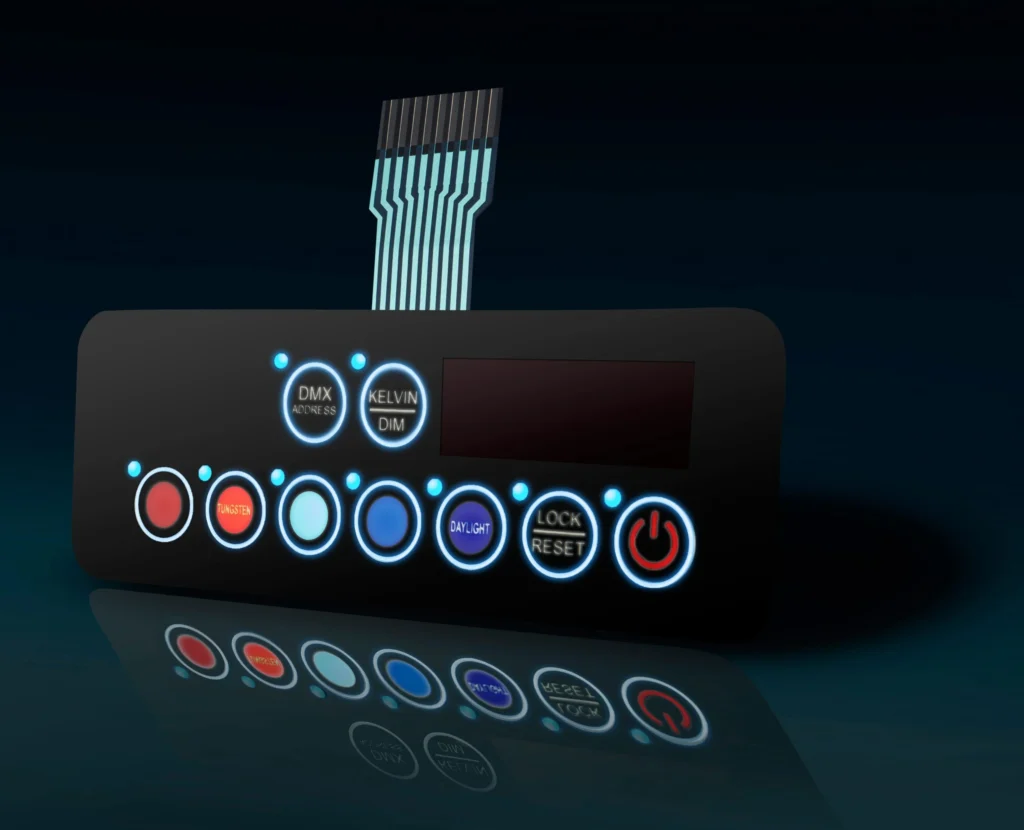

Custom keypads allow for tailored solutions to meet unique requirements. SOUSHINE offers a range of customization options, including different shapes, sizes, and graphics. Customers can select features such as LED illumination for better visibility or EMI/RFI shielding for protection against interference. These options help ensure the tactile membrane switch keypad fits the specific needs of each application.

- LED illumination improves visibility in low-light conditions.

- EMI/RFI shielding protects against electronic interference.

- Custom graphics and layouts support brand identity.

SOUSHINE’s membrane switch solutions combine advanced features with flexible design. The company supports integration of tactile switch elements, backlighting, and shielding to enhance performance. This approach ensures each tactile membrane switch keypad meets the demands of its intended environment.

Advantages and Disadvantages

Pros

Tactile membrane switches offer several important benefits for user interface design and device performance.

- Tactile feedback improves the user experience by providing a clear response with each press. Users feel confident that their input has registered.

- Customizable overlays allow for vibrant colors and unique graphics. Devices can match brand identity and improve visual appeal.

- Protective coatings and seals keep out moisture, dust, and contaminants. This design ensures long-lasting performance in harsh environments.

- The sealed construction prevents contaminants from reaching the circuitry. This feature extends the lifespan of equipment in industrial and medical settings.

- SOUSHINE uses high-quality materials such as PET, PC, PVC, and rubber. These materials resist wear and tear, even in demanding conditions.

- Membrane switches have no moving parts. This reduces the risk of malfunction and increases reliability.

- Cost-effective production makes membrane switches suitable for medium-to-high volume manufacturing.

- Flexible design options support integration of features like LED backlighting and EMI/RFI shielding.

Note:

Many membrane switches meet IP65, IP66, or IP67 standards. These ratings mean the switches are dust-tight and protected against water, making them suitable for challenging environments.

| Feature | Membrane Switch | Mechanical Switch |

|---|---|---|

| Cost | Lower | Higher |

| Tactile Feedback | Moderate | Strong |

| Durability (cycles) | 1-5 million | 10-100 million |

Cons

Tactile membrane switches also have some limitations that users should consider.

- The travel distance of each key depends on the design and force required. Some users may prefer a longer or shorter travel.

- Membrane switches tend to wear out faster than mechanical switches. The lifespan is lower, especially in high-use applications.

- Repairing individual keys is not practical. If one key fails, users often need to replace the entire switch.

- The tactile switch may not provide as strong a response as some mechanical alternatives.

SOUSHINE addresses these challenges by selecting durable materials and advanced sealing methods. Their membrane switch products maintain performance and reliability, even in harsh environments.

What Is a Membrane Switch Used For

Consumer Electronics

Membrane switch technology appears in many consumer electronics. Manufacturers use these switches in remote controls, microwave ovens, and fitness equipment. The low-profile design allows for sleek interfaces. Users press-activated tactile membrane switches to control devices with accuracy. The tactile switch provides clear feedback, which improves user confidence. SOUSHINE integrates advanced features such as LED backlighting and EMI/RFI shielding. These enhancements support reliable operation in environments with electronic interference. The switches resist moisture and dust, which extends product life. SOUSHINE customizes membrane switch layouts to match brand identity and device requirements.

Medical Devices

Medical devices require reliable and hygienic user interfaces. Membrane switch solutions meet these needs with sealed, wipe-clean surfaces. The smooth overlay resists disinfectants and supports easy cleaning. This design reduces contamination risk and supports infection control. Medical membrane switches meet IP66/67 standards, which ensures durability in harsh environments.

Membrane switches are fully sealed, wipe-clean, and withstand disinfectants—meeting IP66/67 standards. Compared to mechanical switches, membrane switches offer longer uptime, fewer service events, and reduced contamination risk.

Healthcare professionals rely on tactile feedback for precise operation. The tactile switch design ensures each input registers accurately. Where are tactile switches used? They appear in patient monitors, infusion pumps, and diagnostic equipment. SOUSHINE tests each membrane switch for reliability and calibrates sensors for accuracy. The company adapts membrane switch solutions to meet specific medical device requirements.

- Tactile membrane switches provide tactile feedback, ensuring precise operation in medical devices.

- They are easy to clean, which is essential for maintaining hygiene in healthcare settings.

- These switches are resistant to contamination, making them suitable for critical healthcare applications.

Industrial Controls

Industrial environments demand robust and reliable controls. Membrane switch panels operate machinery, process control systems, and factory automation equipment. The sealed construction protects against chemicals, dust, and moisture. Operators use press-activated tactile membrane switches for consistent performance in harsh conditions. SOUSHINE designs membrane switch solutions to endure extreme environments and frequent use.

- Tactile membrane switches are commonly used in industrial equipment, such as machinery controls, process control panels, and factory automation systems. They are designed to endure harsh conditions, including exposure to chemicals, dust, and moisture.

- Tactile membrane switches are preferred in industrial control panels due to their durability and reliability in extreme environments, including moisture and chemicals.

SOUSHINE customizes sensors and conducts rigorous testing to ensure reliability. The company calibrates each membrane switch for accuracy across different devices. What is a membrane switch used for in industry? It provides a dependable interface for operators, supporting safety and efficiency.

Automotive Interfaces

Automotive manufacturers rely on membrane switch technology to create reliable and user-friendly interfaces inside vehicles. Drivers and passengers interact with these switches every day. They use them to control climate systems, audio equipment, lighting, and seat adjustments. The membrane switch provides a low-profile and sealed solution that fits the demanding environment of a car interior.

SOUSHINE designs membrane switch panels for dashboards, steering wheels, and center consoles. These panels withstand temperature changes, vibration, and exposure to dust or moisture. The sealed construction prevents contaminants from reaching the internal circuits. This design ensures long-term performance and safety.

Automotive engineers select membrane switch solutions for several reasons:

- The switches resist wear from frequent use.

- The sealed surface allows for easy cleaning.

- The design supports integration with LED backlighting for night visibility.

- The low profile fits tight spaces in modern vehicle interiors.

Press-activated tactile membrane switches give drivers a clear response with each press. This feedback helps drivers operate controls without looking away from the road. The tactile response improves safety and reduces distraction.

Note: SOUSHINE offers custom graphics and illumination options. These features help automotive brands create unique and recognizable interfaces.

Where are tactile switches used in vehicles? They appear in window controls, seat adjustment panels, and infotainment systems. The membrane switch also supports touch-sensitive controls for navigation and climate settings. Automotive designers value the flexibility of the membrane switch. They can shape the overlay to match the style of the vehicle.

What is a membrane switch used for in automotive applications? It provides a reliable interface for both drivers and passengers. The switch operates in harsh conditions, including extreme heat, cold, and humidity. SOUSHINE tests each membrane switch for durability and consistent performance.

The company integrates advanced features such as EMI/RFI shielding to protect against electronic interference. This protection is important in vehicles with many electronic systems. SOUSHINE also offers options for haptic feedback and multi-color backlighting.

Automotive manufacturers choose SOUSHINE membrane switch solutions for their durability, flexibility, and ease of integration. The membrane switch continues to play a key role in modern vehicle design.

Tactile membrane switches deliver reliable performance in modern devices. Key benefits include:

- Durability for daily use

- Space-saving design

- Sealed protection against environmental factors

- Enhanced user experience with clear tactile feedback

- Flexible customization

- Easy maintenance

| Feature | Description |

|---|---|

| Tactile Feedback | Confirms actions and improves reliability in electronic devices |

| Customization | SOUSHINE offers tailored solutions for unique applications |

For more on advanced interface technology, explore these resources:

| Resource Type | Description | Link |

|---|---|---|

| Leading Membrane Switch Manufacturers | Information about membrane switches, types, and applications | Visit Here |

| Membrane Switch Applications | Overview of uses across industries | Explore Applications |

| Membrane Switch Design Guide | Guide for designing tailored membrane switches | Download Guide |

FAQ

What is the main benefit of a tactile membrane switch?

A tactile membrane switch gives clear feedback with each press. This feedback helps users know when the device registers their input. The design improves accuracy and confidence during operation.

How do metal dome tactile membrane switches differ from poly dome types?

Metal dome tactile membrane switches use a metal dome to create a crisp snap and strong feedback. Poly dome types use flexible plastic, which gives a softer feel and quieter operation.

Can SOUSHINE membrane switches withstand harsh environments?

SOUSHINE membrane switches resist moisture, dust, and chemicals. The sealed construction protects internal circuits. These switches work well in medical, industrial, and automotive settings.

Are membrane switches customizable for different user experience needs?

SOUSHINE offers custom graphics, shapes, and features. The company adapts each switch to meet specific user experience needs. Options include LED backlighting and EMI/RFI shielding.

What is the typical lifespan of a tactile membrane switch?

A tactile membrane switch usually lasts between 5 and 10 million presses. The lifespan depends on materials and usage conditions. SOUSHINE uses high-quality materials for long service life.

Where are tactile membrane switches commonly used?

Tactile membrane switches appear in medical devices, industrial controls, consumer electronics, and automotive interfaces. Their reliable feedback and sealed design suit many applications.

Can membrane switches include lighting or shielding features?

SOUSHINE membrane switches can include LED backlighting for visibility and EMI/RFI shielding for protection. These features improve usability and device safety.