Call us: +86-137-2353-4866

A force sensing resistor is a sensor that detects force or pressure by changing its electrical resistance. So, what is force sensing resistor exactly? When you press on a force sensing resistor, its resistance decreases as the applied force increases. This simple yet effective mechanism allows electronic devices to accurately measure how much force or pressure is being applied. Many beginners and hobbyists are eager to learn about force sensing resistor technology because it enables them to create innovative and interactive projects. SOUSHINE is a leading brand that specializes in force sensing resistor technology, providing precise and reliable solutions for force measurement. The demand for these sensors continues to grow rapidly, as reflected in the market data below.

| Year | Market Size (USD Million) | CAGR (%) |

|---|---|---|

| 2024 | 36 | – |

| 2031 | 87.7 | 13.5 |

Table of Contents

Key Takeaways

- Force sensing resistors (FSRs) notice pressure by changing resistance when pressed. FSRs are thin and bend easily. They are simple to use. This makes them great for small spaces and wearable gadgets. They give steady and correct force readings at many pressure levels, not just on or off. FSRs are cheap and easy compared to other force sensors. They work well in robots, medical tools, and electronics people use every day.

- There are different kinds of FSRs, like shunt mode and thru-mode. These types help with strong pressure or gentle touches. FSRs link to microcontrollers with a voltage divider circuit. This changes resistance into signals we can read. People use FSRs for touch buttons, robot grip checks, health monitors, and car safety. Making simple FSR projects with Arduino helps students learn about force, electronics, and coding.

What Is Force Sensing Resistor

Force Sensitive Resistor Definition

A force sensitive resistor is a sensor that changes resistance when you press on it. This sensor uses special technology to sense how much force is there. When you push on the sensor, its resistance goes down. The sensor sends this data to an electronic system. The system can then measure the exact force you use. Many engineers and designers like force sensing resistors. These sensors are thin, bendy, and simple to use. The technology lets the force sensing resistor fit in tight spaces. It also works well in many places.

SOUSHINE uses a special technology in its force sensing resistors. Each sensor has a bendy base and a special circuit. A thin layer sits on top of the circuit. When you press down, the layer touches the circuit. This makes the resistance change. This design helps the sensor measure force all the time, not just on or off. The force sensing resistor can sense both soft and hard presses. This makes it useful for many things.

Tip: Force sensing resistors are best for measuring changing force, not just simple taps.

FSR vs. Other Sensors

There are many sensors that can measure force or pressure. Each one uses different technology and works best in certain ways. The table below shows how force sensing resistors compare to other sensors:

| Sensor Type | Sensitivity | Accuracy and Stability | Notes on Measurement Capability and Limitations |

|---|---|---|---|

| Piezoresistive | High sensitivity, especially at low pressures | Can have errors from temperature; needs fixing; may change over time | Good for steady and moving pressures; output matches pressure; affected by temperature |

| Capacitive | Not as sensitive as piezoresistive | More accurate in different temperatures; not much error from heat | Strong and steady; good for low power and wireless; can be shaken by vibration; output is not always straight but can be fixed |

| Piezoelectric | Very sensitive to quick pressure changes | Very accurate for moving pressures; not good for steady pressures | Makes its own power; not bothered by electromagnetic noise; needs special electronics; only works for moving pressure |

Force sensing resistors are special because they are simple and cheap for measuring force. They do not need fancy electronics or fixes for temperature. Many engineers pick force sensing resistors when size, bendiness, and price are important. For example, in prosthetic devices, force sensing resistors help measure pressure between a limb and its socket. Their thin shape does not get in the way, and their low price is good for making many at once.

In hand gesture systems, force sensing resistors sense muscle movement by measuring pressure on the skin. Their easy design and simple setup make them great for wearable tech. Other sensors might be more accurate or sensitive sometimes. But force sensing resistors work well in many real-life uses. Their technology lets people measure force in lots of products, like medical tools and electronics.

Force Sensing Resistor Working Principle

Detection Principle

A force sensing resistor finds pressure by changing its resistance. This sensor works using piezoresistivity. When you push on it, the particles inside move closer together. This makes more paths for electricity to travel. As a result, the resistance goes down. The sensor turns this change into an electrical signal. The link between force and resistance is not always straight, so calibration is needed for good results.

The science behind force sensing resistors is shown in the table below:

| Principle | Description | Effect on Resistance with Applied Force |

|---|---|---|

| Percolation | When there are enough particles, force pushes them apart. | Resistance goes up as particles move away from each other. |

| Quantum Tunneling | When there are fewer particles, force brings them closer together. | Resistance goes down as electrons can move more easily. |

| Contact Resistance | Force makes the contact area bigger between the electrodes and polymer. | Resistance drops because the contact gets better. |

This table explains how force sensing resistors turn force into a change in resistance. The sensor can measure force by watching how much the resistance drops when you press on it.

Operation

Conductive Materials

SOUSHINE uses new technology in its force sensing resistors. Each sensor has a bendy base with a special circuit printed on it. A unique conductive layer sits on top of this circuit. A thin spacer keeps the layers apart when no one is pressing. The conductive layer has special particles that react to pressure. When you press down, the particles move closer together. This makes more paths for electricity.

- The main parts of a SOUSHINE force sensing resistor are:

- Flexible base

- Special circuit

- Unique conductive layer

- Spacer

This setup helps the sensor find even small changes in pressure. The bendy design lets the sensor fit in many devices and uses.

Resistance Change

When you press on the sensor, the conductive layer touches the special circuit. The area where they touch gets bigger as you press harder. This makes the resistance go down. The sensor connects to a voltage divider circuit. This circuit changes the resistance into a voltage signal. A microcontroller reads this signal and figures out the force.

The steps for how it works are:

- You press on the sensor, squishing the conductive layer.

- The resistance of the force sensing resistor goes down as you press harder.

- The sensor connects to a voltage divider with a fixed resistor.

- The voltage across the fixed resistor is checked by an analog input.

- The microcontroller changes this voltage into a digital number.

- Software figures out the resistance and the force.

- The system uses this information for more actions or output.

SOUSHINE force sensing resistors give steady and exact force measurement. Their technology makes sure the results are accurate and repeatable. The sensors can sense many levels of pressure, not just on or off. This makes them great for jobs that need real-time force measurement. SOUSHINE sensors have high linearity and quick response times. Their bendy design and strong performance help in many areas, like robots, medical tools, and electronics.

Note: SOUSHINE force sensing resistors give steady results because of their smart design and careful calibration.

Types of Force Sensing Resistors

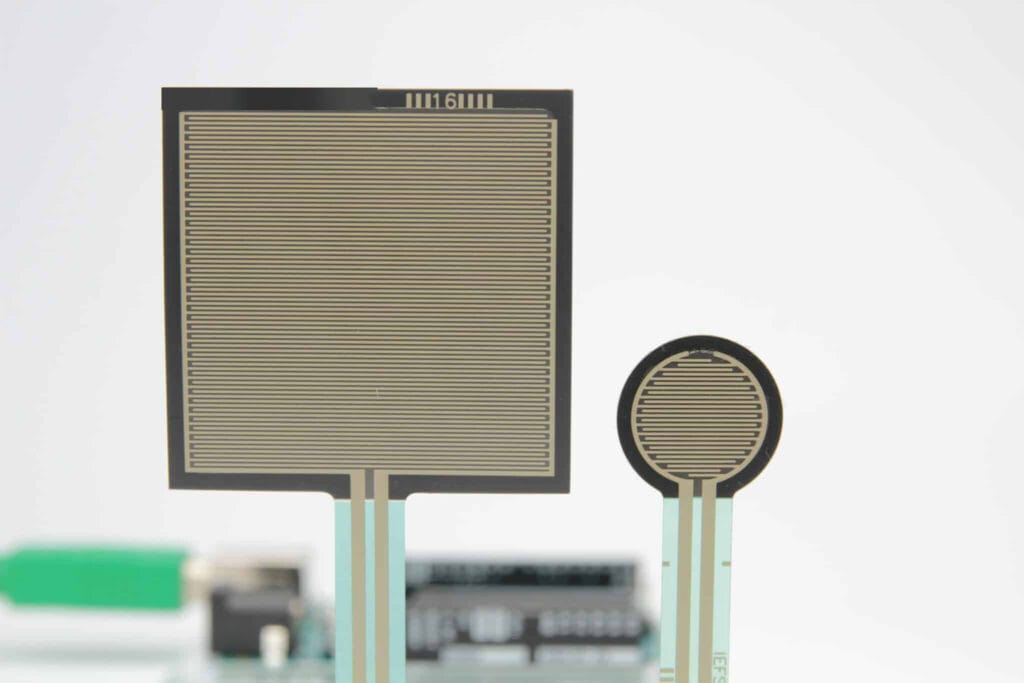

Force sensing resistors come in different types for special jobs. SOUSHINE makes many kinds, like resistive varistors and sensor arrays. This gives engineers choices for many uses.

| Type of Force Sensing Resistor | Description | Typical Applications |

|---|---|---|

| Thin Force Sensors | Lightweight, ultra-thin design for tight spaces | Wearable technology, robotics, automotive sensing |

| Custom Force Sensors | Built to meet unique size or sensitivity needs | Specialized industrial or medical uses |

| Standard Force Sensors | Reliable, mass-produced with fixed specs | Manufacturing, automation, consumer electronics |

Shunt Mode

Shunt mode force sensing resistors have two flexible layers. The top layer has a semiconductive part that connects the bottom layer’s traces. The bottom layer has silver patterns that look like fingers. This design lets the sensor feel many force levels. Shunt mode sensors are good for high pressure jobs.

- Two PET layers: one with silver patterns, one with a carbon layer

- Can sense many different forces

- Used in airbags, shoe insoles, hospital beds, and grip sensors

- Thin and bendy, fits in lots of products

| Characteristic | Value |

|---|---|

| Force Repeatability | ±15% part-to-part |

| Force Resolution | 1% full scale |

| Stand-Off Resistance | 10M ohm or greater |

| Device Thickness | 0.017 inches |

| Lifecycle | Over 1 million actuations |

Shunt mode force sensing resistors last a long time and work well. Many industries use them because they are strong.

Thru-Mode

Thru-mode force sensing resistors are made to sense small forces. They react to light pressure, so they help in sensitive places. Thru-mode sensors are found in hospital beds to watch patients or in shoes to check pressure.

- Watches if someone is in a hospital bed

- Checks fluid levels in medical machines

- Measures pressure in shoe insoles for walking studies

- Helps track items on shelves

Thru-mode force sensing resistors make care and safety better in hospitals and factories.

Sensor Arrays

Sensor arrays put many force sensing resistors together in one unit. This lets the system see how force spreads over an area. Engineers use sensor arrays to find pressure patterns, which helps in robots, smart gadgets, and medical tools.

Sensor arrays use special circuits to get data from many spots. Software looks at this data to make a map of force on the surface. This helps find touch, grip, or pressure with good accuracy.

SOUSHINE’s sensor arrays are flexible and can be changed for tough jobs. Their easy design and smart software are great for new electronics.

SOUSHINE’s force sensing resistors can do many things. Their products go from single sensors to big arrays, so they fit many needs.

Force and Resistance Relationship

Force Measurement

Force sensing resistors help devices know how much force is used. These sensors change their resistance when you press on them. Engineers use them to measure things like touch or grip in gadgets. Most force sensing resistors start working at about 20 to 50 grams. Small ones can measure up to 1 kilogram. Bigger models, like the FSRtek Matrix, can sense from 200 grams to 50 kilograms. These sensors are best for checking if something is pressed and how hard, not for exact weight.

- Typical force measurement ranges for force sensing resistors:

- Start working at 20–50 grams

- Small ones: up to 1 kilogram

- Large sensor arrays: up to 50 kilograms

| Sensor Model | Force Measurement Range | Notes |

|---|---|---|

| FSRtek Matrix Force Sensing Resistor 16×16 | 200 grams to 50 kilograms | Can sense light presses at 200g; works up to 50kg; easy to use and not expensive |

The Pololu 1.5″ square force sensing resistor can sense from a few grams to a few kilograms. It shows big resistance changes with small forces. This makes it good for both soft and hard presses.

Resistance Curve

Force sensing resistors have a special resistance curve. When you do not press, the resistance is very high, often in the megaohm range. When you press harder, the resistance drops fast, sometimes to the kiloohm range. The curve is not straight. Resistance falls quickly at first, then slows down as you press more. This happens because of how the sensor’s materials react to pressure.

Inverse Relationship

Force and resistance have an inverse relationship. When you press harder, resistance goes down. A small press makes resistance drop a lot at first. If you keep pressing harder, resistance changes less. The sensor’s conductance, which is the opposite of resistance, goes up more evenly as you press. This helps engineers make circuits that can measure force over a wide range.

Note: The resistance curve helps people set up their systems for the best results.

Common Formulas

Engineers use a voltage divider circuit to read force sensing resistors. The force sensing resistor connects in series with a fixed resistor. When you press, the sensor’s resistance changes. This changes the voltage across the fixed resistor. The formula for the output voltage is:

Vo = Vcc * (R / (R + R_FSR))- Vo: Output voltage

- Vcc: Supply voltage

- R: Fixed resistor value

- R_FSR: Resistance of the force sensing resistor

To find the force sensing resistor’s resistance, use this formula:

R_FSR = ((Vcc - Vo) * R) / VoAfter measuring resistance, engineers use calibration data to guess the force. The link between force and resistance is not a straight line. So, calibration curves or tables from the datasheet help turn resistance into force. This way, force sensing resistors can measure force in many things, like robots or medical tools. The fixed resistor you pick changes how sensitive the measurement is and what range it covers.

Force Sensing Resistor Applications

Consumer Electronics

Force sensing resistors are important in many electronics. They help people use devices in new ways. Many gadgets use them as buttons you do not have to click. You can press softly or hard to do different things. This is found in remotes, touchpads, and smart home panels.

- Hair dryers turn on when you squeeze the handle.

- Stoves know when a pot is on the burner and turn on.

- Smart carpets can tell if someone is there and control lights or music.

- Musical instruments and game controllers use them for better play.

- Stylus pads and signature tools use them for exact input.

These uses show how force sensing resistors make devices easier to use. They help gadgets react faster and feel smarter.

Robotics

Robots need to measure force to work safely. Engineers put force sensing resistors in robot hands and feet. These sensors feel touch and send feedback right away. Robots use this to change their grip and keep balance.

Force sensing resistors are thin and bendy, so they fit on robot hands. Robots use them to feel force in many places at once. This helps robots touch things and people safely. In haptic systems, these sensors match vibration strength. The system uses this to make touch feel real.

Robots also use force sensing resistors with other sensors, like for heat or wetness. This mix helps robots sense better in tricky places. The technology lets robots react fast and handle new things.

Medical Devices

Medical devices need good force measurement to keep patients safe. Force sensing resistors are helpful here. They are thin and bendy, so they fit in small or wearable devices. Prosthetics, catheters, and surgery tools use them to feel touch.

- They are cheap, so many devices can use them.

- Simple electronics make them easy to add to new tools.

- They react fast to pressure changes during medical work.

- They come in many shapes and sizes for different needs.

SOUSHINE force sensing resistors work well and are trusted in real medical use. Wearable blood pressure monitors use them to check pressure all the time. The sensors keep working well after lots of use. Good calibration keeps them accurate for a long time. Their bendy design means people can wear them all day, even when moving or sweating. These things make force sensing resistors a great pick for new medical tech.

Automotive

Force sensing resistors are important in today’s cars. Engineers use these sensors to make cars safer and easier to use. SOUSHINE FSRs are trusted because they measure force very well. They work well in cars because they are reliable.

Car safety systems use FSRs to find out who is sitting in a seat. The sensors check how weight is spread on the seat. The system can tell if it is an adult, a child, or a child seat. This helps airbags work the right way. Airbags can turn off or change how they open to keep people safe. FSRs are hidden under the seat foam and cover. They are thin and bendy, so they do not change how the seat feels.

SOUSHINE FSRs give the right data to help cars know who is in the seat.

FSRs also make it easier for people to use car features. Many cars use FSRs in door handles that pop out when touched. The handle stays flat until the sensor feels a touch. Then the handle comes out so you can use it. FSRs also take the place of buttons on the dashboard. This makes the dashboard look smooth and modern. It also lets car makers add new kinds of controls.

Some ways FSRs are used in cars are:

- Airbag systems that know who is in the seat

- Reminders to put on seat belts

- Door handles that open when touched

- Dashboards with touch controls

- Steering wheels that feel how hard you grip

| Application Area | FSR Function | Benefit |

|---|---|---|

| Airbag Deployment | Finds out who and where is sitting | Makes cars safer |

| Door Handles | Feels when someone touches | Lets handles stay flat |

| Dashboard Controls | Replaces old buttons | Makes cars easier to use |

| Seat Monitoring | Checks how weight is spread | Helps safety systems work |

SOUSHINE FSRs work well even in tough car conditions. Their strong build and good measuring help engineers make cars safer and nicer to use.

Simple Force Sensing Resistor Project

Materials

To make a simple force project, students need some basic parts and tools. These things help you connect the sensor and see how much force is used.

- Force sensing resistor (FSR)

- Arduino board (like Uno or Nano)

- Jumper wires

- Breadboard

- Fixed resistor (4.7 kΩ is best)

- Solder tabs or alligator clips for easy connections

- USB cable for Arduino

- Computer with Arduino IDE

- Soldering iron and solder (for strong connections)

- Wire cutter and knife (to get wires ready)

- Hot glue gun (optional, to hold parts in place)

Tip: Try alligator clips or jumper wires for fast testing with the force sensing resistor.

Steps

Follow these steps to build a simple circuit that checks force with an FSR:

- Put the force sensing resistor on the breadboard.

- Connect one side of the FSR to 5V on the Arduino.

- Attach the other side of the FSR to both the analog pin (A0) and one end of the fixed resistor.

- Connect the other end of the fixed resistor to ground (GND).

- Open Arduino IDE and upload a program that reads the analog value from A0.

- Use this code to check the force:

const int FSR_PIN = A0;

void setup() {

Serial.begin(9600);

}

void loop() {

int fsrValue = analogRead(FSR_PIN);

Serial.println(fsrValue);

delay(100);

}- Open the serial monitor to see the sensor numbers.

- Press on the FSR and watch the numbers change as you push harder.

- For calibration, put known weights on the FSR and write down the numbers. This helps match the sensor value to the real force.

- Make a graph to show how force matches the sensor output.

Note: Calibration makes your force measurements more correct in real projects.

Learning Outcomes

Students who finish this project learn many useful skills. The table below shows the main things students will learn:

| Learning Outcome / Skill Area | Description |

|---|---|

| Understanding FSRs | See how a force sensing resistor changes resistance when pressed |

| Circuit Assembly | Build a simple circuit to check force |

| Arduino Programming | Write code to read force data from the sensor |

| Calibration Techniques | Match sensor numbers to real force values |

| Electronics Concepts | Learn about resistance, voltage dividers, and how sensors work |

- Students watch how pressing changes resistance right away. They learn to connect and program a sensor to check force. The project teaches calibration, which links sensor numbers to real force. Students get practice with basic electronics and microcontroller code. They see how force sensing resistors work in real life.

This hands-on project helps students get ready for more work in robotics, electronics, and using sensors.

Force sensing resistors find force by changing their resistance. They make it easy to measure force in electronics. SOUSHINE gives good force sensors with strong quality checks and helpful support. People think force sensing resistors are simple for projects that need to measure force. These sensors are used in robots, car safety, and medical tools. Force sensing resistors let devices react to touch and grip. Many hobbyists and workers use force sensors for real-life problems. Measuring force with these sensors makes technology more accurate. Force data helps smart systems react and adjust. Trying out force sensing resistors helps people learn new things and create ideas.

FAQ

What is the main function of a force sensing resistor?

A force sensing resistor helps measure force or pressure. When you press on it, its resistance changes. Devices use this change to find out how much force is used.

How accurate are SOUSHINE force sensing resistors?

SOUSHINE force sensing resistors give steady and repeatable results. Their smart design helps them sense force well in many uses. If you calibrate them, they get even more accurate.

Can force sensing resistors detect different levels of pressure?

Yes. Force sensing resistors can sense many pressure levels. When you press harder, the resistance gets lower. This lets devices tell the difference between soft and hard presses.

Are force sensing resistors flexible?

Yes. Most force sensing resistors, like SOUSHINE ones, are made with flexible stuff. This lets them bend and fit into small or curved places in lots of products.

How do you connect a force sensing resistor to a microcontroller?

Connect one side of the force sensing resistor to power. The other side goes to a fixed resistor. The spot where they meet connects to an analog pin. The microcontroller checks the voltage to figure out the force.

What are common uses for force sensing resistors?

Force sensing resistors (FSRs) are widely used across various industries due to their ability to detect pressure, weight, and force through resistance changes. In consumer devices, they are commonly found in applications such as touchpads and remote controls, where they help detect user input with varying pressure levels. In the field of robotics, FSRs are used in grippers and foot sensors to enable robots to respond dynamically to their environment and handle objects with appropriate force. Medical devices also benefit from force sensing technology, particularly in prosthetics and patient monitoring systems, where accurate force feedback is critical for functionality and safety. In the automotive sector, FSRs are integrated into seat occupancy detection systems and control interfaces to enhance user experience and safety features.

Do force sensing resistors need calibration?

Yes. Calibration helps match the sensor’s numbers to real force. This makes sure the readings are right for each job.