Call us: +86-137-2353-4866

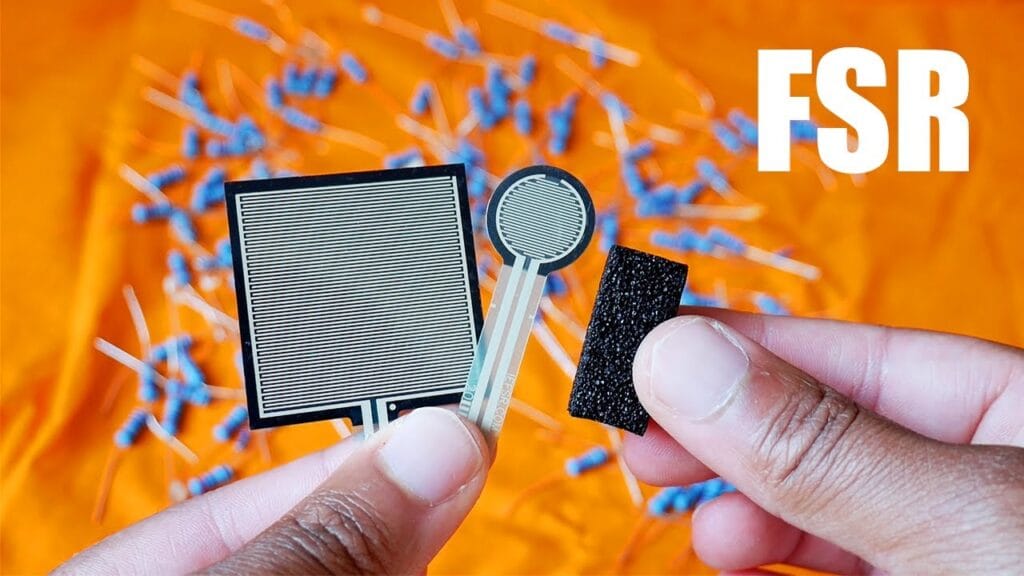

You might be asking, what is force sensing resistor technology and how does it operate? Here are three key things you should know about force sensing and force sensing resistor materials:

- Each force sensing resistor contains a unique conductive polymer that changes its resistance when force is applied, enabling precise force sensing.

- The design of a force sensing resistor features a flexible base and a spacer, allowing for accurate measurement of pressure and effective force sensing.

- Engineers choose these materials for force sensing because they provide reliable performance and long-lasting durability.

SOUSHINE is a leader in force sensing resistor technology, utilizing the piezoresistivity principle to deliver highly accurate force sensing results.

Table of Contents

Key Takeaways

- Force sensing resistors use a special conductive polymer. This polymer changes resistance when force is applied. This helps measure force very accurately.

- These sensors have a flexible design with layers. The layers help them measure pressure well.

- SOUSHINE’s technology is very accurate and strong. It can be changed to fit different needs. Many engineers like it.

- Force sensing resistors can measure many kinds of force. They work for light touches and heavy weights. This makes them useful in many ways.

- Using conductive polymer materials helps lower the cost to make these sensors. It also keeps the sensors working well and strong.

- Force sensing resistors are flexible and can fit in many products. They are used in medical devices and smart gadgets.

- SOUSHINE has eco-friendly choices, like recyclable materials. This helps make sensor technology better for the environment.

- Picking the best materials and designs for force sensing resistors is important. It helps them work well and last long in different places.

What Is Force Sensing Resistor Technology

Force sensing resistor technology helps you measure force and pressure. People use these sensors in robots, cars, hospitals, and gadgets. The sensors use piezoresistive sensors to change force into electricity. SOUSHINE’s force sensing resistor technology is known for being accurate and tough. It is also easy to use in different products.

Piezoresistivity Principle

Piezoresistive sensors work by changing resistance when you push on them. This idea is called piezoresistivity. It is the reason force sensing resistor technology works.

Resistance Change Under Force

Here is how the piezoresistive effect works in these sensors:

- The piezoresistivity principle shows how resistance changes with force.

- Force sensing resistors are variable resistors. When you press them, resistance goes down.

- This lets you measure force very well.

- If you do not press, resistance stays high (Megaohms).

- If you press, resistance drops to lower numbers (Kiloohms).

- This happens because of the piezoresistive effect.

Continuous Force Measurement

Force sensing resistor technology lets you measure force all the time. You do not just get a yes or no answer. You see many numbers that show how much force you use. This makes force measurement systems more helpful and flexible. You can use these sensors in smart gadgets, medical tools, and controls. Piezoresistive sensors help you notice even small changes in pressure. This is important for measuring force exactly.

FSR Construction Overview

Force sensing resistors have many layers. Each layer has a job and a special material. SOUSHINE uses strong materials and smart designs. This makes their force sensing resistor technology last a long time and work well.

Substrate, Spacer, Conductive Layer

Look at the main layers in force sensing resistors in this table:

| Layer | Description |

|---|---|

| 1st Layer | Flexible polymer with special force-sensing ink |

| 2nd Layer | Flexible polymer with conductive ink and special electrodes |

| Spacer | Sticky layer that keeps the other layers apart |

These layers work together to make a piezoresistive sensor. The flexible polymer gives strength and bends easily. The force-sensing ink and conductive ink help measure force. The spacer keeps the layers apart until you press down.

SOUSHINE’s force sensing resistors use bendy polyester films for the base. Silver-based inks make the sensors sensitive and fast. Carbon-based inks make them tough and less expensive. SOUSHINE picks these materials to make great force measurement systems.

Flexible Design

You can bend and shape force sensing resistors for many uses. The flexible design lets you put them on curved or small spaces. SOUSHINE lets you choose the size and shape you need. Their force sensing resistor technology works in many fields because it is flexible.

SOUSHINE’s force sensing resistors are better than many others. Here is a table that shows how SOUSHINE’s technology compares:

| Feature | SOUSHINE’s Technology | Competitors |

|---|---|---|

| Accuracy | High | Lower |

| Durability | Long-lasting | Varies |

| Customization | Many choices | Fewer choices |

| Power Consumption | Low | Higher |

| Integration Ease | Simple | Harder |

SOUSHINE gives you force measurement systems that are reliable and accurate. Their piezoresistive sensors and good materials make them a top pick for engineers and designers.

Conductive Polymer Materials

You use conductive polymer materials in force sensing resistors. These materials help measure pressure and force. SOUSHINE uses advanced conductive polymers. They let you pick the shape, size, and sensitivity you want. You can choose what fits your needs.

Semi-Conductive Ink

Semi-conductive ink is important in force sensing resistors. There are different types of ink in these sensors. Each type helps measure pressure and force.

- Silver Ink

- Carbon Ink

- Dielectric Ink

- PTC Ink

- Silver/SilverChloride Ink

- Silver Plated Copper

- Black Non-conductive Ink

Many force sensing resistors use carbon-based inks. These inks change resistance when you press on them. This change helps you measure force and pressure well.

Embedded Conductive Particles

Manufacturers put tiny conductive particles in the ink. These particles help the sensor react to pressure. You can see the average size of these particles in the table below:

| Mean Particle Size (nm) | Description |

|---|---|

| 70 ± 1 | Average size of silver nanoparticles synthesized |

| < 84 | 90% of nanoparticles have a diameter less than this |

| 20 | Mean size of AgNPs dispersed in poly(acrylic acid) |

Small particles make the ink more sensitive. You get better pressure measurement and faster response.

Polymer Thick Film (PTF) Devices

Polymer thick film devices are used in many force sensing resistors. These devices have layers of conductive ink on flexible bases. The ink forms a network that changes resistance when pressed. SOUSHINE uses PTF technology to make sensors that work well in many places.

Material Response to Pressure

Conductive polymer materials react in different ways to pressure. How they respond affects how well you can measure force and pressure.

Sensitivity and Reliability

Conductive polymer composites act differently based on how many particles they have. If there are few particles, resistance drops as pressure goes up. This happens because electrons move between particles. If there are many particles, resistance rises with more pressure. This means the sensor works in a new way. SOUSHINE’s force sensing resistors can sense light touches as low as 0.2N and heavy weights over 100N. You get good pressure measurement for many needs.

| Force Detection | Range |

|---|---|

| Light Touch | 0.2N |

| Heavy Weights | Over 100N |

You can trust these sensors for gentle or strong pressure. SOUSHINE makes sensors that are sensitive and last a long time.

Cost and Manufacturing Benefits

Conductive polymer materials save you money. They are easy to make and print. You can produce many force sensing resistors at a lower cost. SOUSHINE gives good prices and flexible manufacturing. You save money and get quality sensors for your projects.

Tip: You can ask SOUSHINE for custom force sensing resistors. Their team helps you pick the right material and design for your needs.

Conductive polymer materials are important for pressure measurement. They help you get accurate, reliable, and affordable force sensing resistors for many uses.

Substrate and Spacer Layers in Force Sensing Resistors

You should know how substrate and spacer layers help force sensing resistors work. These layers help the sensor feel pressure and stress. SOUSHINE gives you many choices for substrate materials. You can pick the one that fits your project best.

PET and Polyester Films

Polyethylene terephthalate (PET) and polyester films are used a lot in force sensing resistors. These materials are common because they handle stress well.

Mechanical Properties

PET and polyester films bend and stretch without breaking. You can use them where sensors get pressed or bent many times. These films keep their shape and protect the sensor from harm.

Here is a table that shows how PET compares to other materials:

| Material | Key Properties | Durability Factors |

|---|---|---|

| PET | Flexibility, Stretchability, Chemical Stability | Resistance to moisture, chemical corrosion, temperature changes |

| TPU | Flexibility, Stretchability | Similar durability as PET |

| PI | Flexibility, Thermal Stability | Very strong in tough conditions |

Durability and Flexibility

You want your sensor to last a long time. PET and polyester films do not get damaged by water or chemicals. They also handle hot and cold temperatures. These features help the sensor work in hard places. You can bend these films to fit curved or small spaces. SOUSHINE lets you pick the thickness and size you need.

Tip: Flexible substrates help force sensing resistors work in smart surfaces, medical tools, and wearable devices.

Alternative Substrate Materials

You might need other materials for special projects. SOUSHINE offers polycarbonate, thin metal sheets, and circuit boards. Each material handles stress in its own way.

Polycarbonate, Thin Metal, Circuit Boards

Polycarbonate is strong and does not break easily. Thin metal sheets are tough and help with heat. Circuit boards make it easy to add sensors to electronics. You can choose the substrate that fits your needs.

Application-Specific Choices

New designs use textile-based piezo-resistive materials and embroidered e-threads. These new materials can replace older ones like Velostat. You can put sensors into clothes or soft things. This helps you measure pressure and stress in new ways.

You should think about where your sensor will be used and what kind of pressure it will face. The right substrate helps your force sensing resistors last longer and work better. SOUSHINE helps you pick the best substrate for your job, whether you need it to bend, be strong, or have special features.

Note: Substrate and spacer layers are important for how your sensor feels pressure and stress. Picking the right material helps you get good results and sensors that last.

Electrode Materials and Signal Collection

Electrodes help collect signals from force sensing resistors. You need good electrode materials for accurate force readings. SOUSHINE uses advanced technology for reliable results.

Silver and Carbon Inks

Silver ink and carbon ink are common in force sensing resistors. These inks make patterns that carry electrical signals.

Conductive Patterns

Sensors use these inks:

- Silver Ink

- Carbon Ink

Engineers print the inks on flexible bases. Silver ink makes very conductive paths. Carbon ink is cheaper and works for most uses.

Signal Transmission

Ink conductivity affects how well signals move. Here is a table comparing the inks:

| Type of Ink | Conductivity Level |

|---|---|

| Silver Conductive Ink | Highest electrical conductivity, ideal for high-performance applications |

| Carbon Conductive Ink | Moderate electrical conductivity, sufficient for general-purpose applications |

Silver ink can reach about 105 S/m. Carbon ink is usually between 100 and 1,000 S/m. Silver ink gives faster and clearer signals. It is best when you need high accuracy.

Interaction with Sensing Layer

Electrodes must work well with the sensing layer. SOUSHINE designs electrodes to match the force-sensing material.

Minimizing Signal Loss

You want low signal loss. SOUSHINE uses thin film layers in sensors. One layer holds the resistive material. Another connects to the circuit. This helps the sensor react quickly to force.

Tip: Fast resistance changes help the sensor notice small pressure differences.

Enhancing Accuracy

SOUSHINE picks materials and designs for your needs. They use bendy bases for flexible sensors. Strong plastics are used for tough jobs. Their electrode designs give high sensitivity and repeatability. You can trust the sensor to measure force accurately.

| Feature | Description |

|---|---|

| Thin Film Layers | Uses two layers: one with resistive material and another with the circuit. |

| Quick Resistance Changes | The resistive layer reacts fast to force, improving measurement accuracy. |

| Design Flexibility | Sensors can be tailored for different uses, ensuring high sensitivity. |

SOUSHINE’s electrode technology gives reliable signal collection. You get precise force detection. The right electrode material helps your force sensing resistors work their best.

FSR vs. Other Sensor Technologies

When you compare sensors, you will notice that force sensing resistors have special material benefits. SOUSHINE’s force sensing resistors are different from capacitive and piezoelectric sensors. You can use them in many fields, like healthcare and robotics.

Unique Material Advantages

Flexibility and Cost-Effectiveness

Force sensing resistors are more flexible than most other sensors. You can make them fit almost any space. They work in small smartwatches and big car seats. This makes them good for both tiny and large uses. You can use force sensing resistors with many materials. Capacitive sensors usually only work with certain materials.

Here is a table that shows how force sensing resistors and capacitive sensors compare:

| Advantage | FSRs | Capacitive Sensors |

|---|---|---|

| Material Compatibility | Works with various materials | Limited to specific materials |

| Environmental Resilience | Less affected by humidity | Performance can vary with conditions |

Force sensing resistors also cost less than many other sensors. If you need lots of sensors, they help you save money. Basic force sensing resistors cost about $10 to $50. Some advanced sensors can cost much more. This price difference makes force sensing resistors a smart pick for big projects.

- Force sensing resistors are great for projects needing many sensors.

- You spend less when you use force sensing resistors for simple or big jobs.

Energy Efficiency

Force sensing resistors use very little power. You can put them in battery-powered devices. This helps your gadgets last longer before charging. You see this in wearable tech, medical tools, and smart home products.

Limitations and Considerations

Sensitivity Range

Force sensing resistors work for many things, but you should know their sensitivity limits. They measure many forces, but some jobs need more exact sensors. You can trust force sensing resistors for most daily uses, like car seats or shoe insoles.

Environmental Factors

You should think about where you use force sensing resistors. Heat and humidity can change their readings. High heat may change the sensor’s normal resistance. Humidity can also affect resistance. You might need to adjust your force sensing resistors if you use them in tough places.

| Variable | Impact on Sensor Performance |

|---|---|

| Temperature | Affects sensor conductance and force readings. |

| Curvature | Influences calibration curves of the FSRs. |

| Tissue Compliance | Alters sensor performance and requires independent calibration. |

Note: Always check your sensor’s settings if you use it where temperature or humidity changes a lot.

Application Scenarios and Industry Relevance

You can use force sensing resistors in many areas. Here are some examples:

- Athletic Apparel: Shoe insoles that sense foot pressure.

- Medical Applications: Tools for medicine control and hospital beds.

- Robotics: Feedback for robot arms.

- Inventory Control: Shelf sensors for tracking items.

- User Interface Controls: Buttons that do not need to be touched.

- Automotive: Car seat sensors and touch controls.

- Healthcare: Wearable monitors and smart artificial limbs.

- Wearable Tech: Controls for phones and smartwatches.

Force sensing resistors give you a reliable and flexible way to measure force. They also help you save money. SOUSHINE’s special materials and designs help you get the best results for your needs.

Future Trends in Force Sensing Resistor Materials

You will notice big changes in force sensing resistor materials soon. New research and technology help make sensors better for your projects. SOUSHINE is leading with new materials and smart ways to make sensors.

Emerging Materials

Nanomaterials

Nanomaterials make force sensing resistors more sensitive and tough. Inside the sensor’s polymer layer are tiny conductive nanoparticles. These small particles help the sensor react fast to pressure. When you press the sensor, the particles move and change resistance. This lets you measure force very accurately.

- Nanomaterials form nanocomposites with strong piezoresistive effects.

- Conductive nanoparticles are spread randomly in the polymer. This changes how sensitive the sensor is.

- You can change the input voltage to make the sensor more sensitive and repeatable.

Sensors can notice even small changes in force. This helps in medical devices, smart wearables, and robots.

Hybrid Composites

Hybrid composites mix different materials to make sensors stronger and more bendy. Some sensors have layers of polymers, metals, and textiles. These layers work together to give better results.

- Hybrid composites make sensors last longer and bend more.

- You can use these sensors in hard places and on curved things.

- These materials help you get good readings for a long time.

SOUSHINE uses hybrid composites to make sensors for many jobs. You can trust these sensors to last and work in many places.

Sustainability

Recyclable Substrates

You want sensors that are good for the earth. Recyclable substrates help cut down on waste. SOUSHINE has sensors with PET and other recyclable films. You can use these sensors and recycle them when you are done.

- Recyclable substrates help lower plastic waste.

- You help the planet by picking eco-friendly materials.

Green Manufacturing

Green manufacturing changes how companies make force sensing resistors. More factories now use less energy and make less pollution. SOUSHINE uses smart factory tech to save energy and lower emissions. Data and analytics help factories use fewer resources and work better.

Environmental rules make companies use safer materials and cut waste. More products are made with green methods now. Companies that care about the earth stand out in the market. You help the planet when you pick sensors from brands that use green manufacturing.

Tip: You can ask SOUSHINE about their eco-friendly choices and how they help with sustainability in your projects.

You will see more force sensing resistors made with new materials and green ways. These changes help you get better sensors and protect the earth at the same time.

You have learned three important things about force sensing resistor materials. Using the right materials helps FSRs sense force better. Good materials also make sensors last a long time. They are easy to use with other systems.

| Key Fact | Description |

|---|---|

| Sensitivity | Materials help FSRs sense force well. |

| Durability | Strong materials help sensors last longer. |

| Integration | FSRs work with many types of technology. |

SOUSHINE is a leader in making new materials and custom sensors. When picking FSRs, think about the shape, size, and material. This helps you get the best sensor for your needs.

FAQ

What is a force sensing resistor (FSR)?

A force sensing resistor helps you measure force or pressure. When you push on it, its resistance changes. This lets you know how much force you use.

Which materials make up a force sensing resistor?

Most FSRs have flexible polymers and conductive inks like silver or carbon. There is also a spacer layer. These parts work together to sense pressure.

How do FSRs measure force?

You push on the sensor. The resistance gets lower as you press harder. A simple circuit can read this change.

Where can you use force sensing resistors?

FSRs are used in robots, cars, medical tools, and smart gadgets. They come in many shapes and sizes. You can use them almost anywhere.

Why do engineers choose FSRs over other sensors?

FSRs are flexible and cost less. They are easy to add to many things. They use little power and work in many places.

Can you customize the shape and size of an FSR?

Yes! You can pick different shapes, sizes, and how sensitive they are. SOUSHINE gives you many choices for your project.

How long do force sensing resistors last?

FSRs last a long time. They are made from strong materials. These materials resist damage from water and heat.

Are FSRs safe for wearable devices?

Yes, FSRs are safe for wearables. They are thin and bend easily. You can wear them on your skin without worry.