Call us: +86-137-2353-4866

Tactile sensing helps devices feel touch, pressure, and force. This technology uses special sensors to measure how much force or pressure is on a surface. Tactile sensors come in many types and help machines know about contact. They can tell how hard someone presses a button or if something is squeezed. For example, resistive sensors use a force sensing resistor. This resistor changes its resistance when force is put on it. Here is how some common tactile sensors work:

| Sensor Type | Mechanism Description |

|---|---|

| Strain Gauges | Finds changes in length of a material when outside forces push or pull, used in load cells or robot hands. |

| Capacitive Sensors | Measures changes in capacitance when metal parts move, so it can tell how much pressure is there. |

| Resistive Sensors | Uses special materials that change resistance when pressed, which helps make a picture of the touch. |

Tactile sensing is important in our lives today. Devices like smartphones, robots, and cars use tactile technology all the time. The world market for tactile sensors was worth USD 12.85 billion in 2024. It may grow to USD 33.20 billion by 2032. This shows how important force sensing is now.

Table of Contents

Key Takeaways

Tactile sensing lets machines feel things like touch and pressure. It uses special sensors to do this. There are different kinds of tactile sensors. Some are resistive, some are capacitive, and some are piezoelectric. Each type works in its own way. Tactile sensors help robots work with people. They let robots do gentle tasks safely. These sensors are very important in healthcare. They help doctors watch patients and improve prosthetic devices. Tactile sensing technology is growing fast. The market for it will get much bigger soon. Tactile sensors are used in many things. They are in electronics and in factories. They make devices smarter and safer. Tactile sensors give feedback to users. This makes things like phones and game controllers better to use. In the future, sensors will get smaller. AI will help them process data faster.

Tactile Sensing Overview

Definition

Tactile sensing lets machines know when they are touched. It helps them feel pressure and force. Sensors react when they touch something. These sensors can check pressure, force, slip, and temperature. Tactile sensing is like how our skin feels things. The table below gives two scientific definitions:

| Definition | Description |

|---|---|

| Tactile Sensor | Sensing parts that measure things by touching objects. They give details about pressure, force, slip, vibrations, temperature, and moisture. |

| Tactile Sensor | A device that gets information from touching things. It is made to work like human skin. |

Tactile sensing lets machines “feel” what is around them. This helps them notice changes and act more like people.

Purpose

Tactile sensing helps machines learn about their world. Robots and devices use tactile sensors for careful tasks. The table below shows some main reasons for using tactile sensing:

| Objective | Description |

|---|---|

| Paradigm Shift | Changes how robots sense and deal with their world. |

| Empower Interactive Robots | Lets robots do tricky jobs that need skill. |

| Enhance Perception | Makes robots and devices sense things better. |

| Enable Complex Tasks | Helps with grabbing soft or strange-shaped things. |

| Improve Human-Robot Interaction | Checks touch and force for safe teamwork with people. |

| Mimic Human Capabilities | Lets robots copy how people touch and move. |

| Enhance Interaction | Helps machines work with their world in a smarter way. |

Tactile sensing lets robots pick up breakable things. Prosthetic hands can feel touch. Devices can give feedback when you press them.

Importance

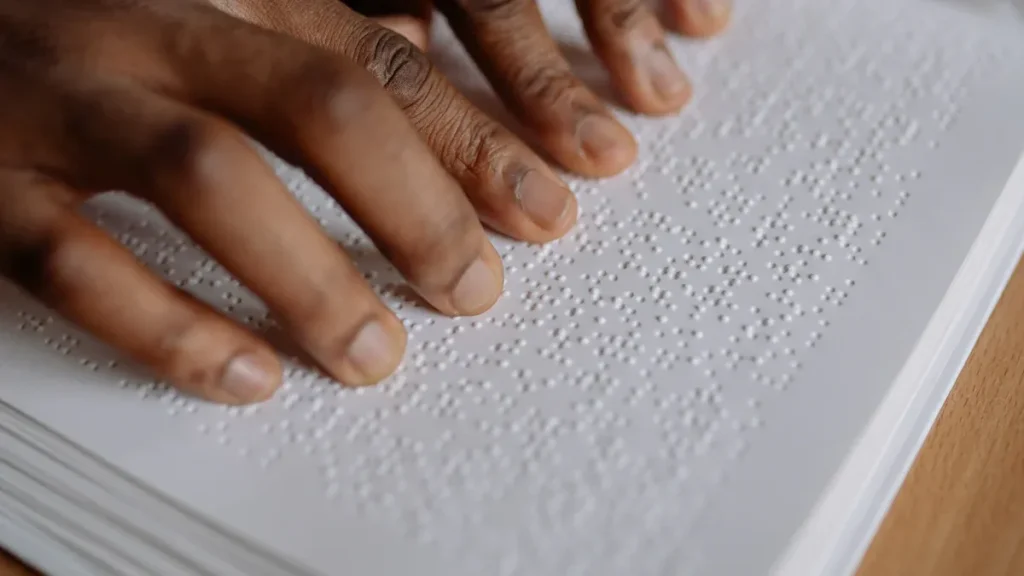

Tactile sensing makes technology easier and nicer to use. Devices with tactile sensors help people with disabilities. They give feedback by touch or vibration. Haptic feedback helps blind users feel vibrations to guide them. Accessibility tools use touch feedback to make apps easier.

- Flexible tactile sensors can bend and sense small changes.

- In robots, tactile sensing helps grab and move things better.

- Prosthetic hands use tactile sensors to help people feel touch.

- Virtual reality uses touch feedback so users can feel things in games.

Tactile sensing helps people and machines work together. It makes devices smarter and quicker to react. This leads to better experiences for everyone.

Tactile Sensing Principles

Main Components

Tactile sensing uses a few important parts. Each part helps collect and use touch information.

Sensing Surface

The sensing surface touches objects first. It can be soft or hard. The type depends on how it will be used. Many surfaces have a grid or pattern. This helps find where the touch happens. When you press the surface, it sends signals. These signals go to other parts of the system. The surface must be strong and bendable. Many sensors use thin, flexible materials. This lets them fit into many shapes and devices.

Signal Processing

After the surface feels a touch, signal processing starts. This part reads signals from the surface. It turns them into data. It checks the force or pressure. The system then picks what to do next. For example, if a robot hand feels something soft, signal processing tells it to grip gently. Signal processing helps understand the data. It gives clear steps to the device.

How Tactile Sensors Work

Tactile sensors measure force and pressure. They do this by changing electrical resistance. This is how tactile sensing works in many devices. Here is a simple way to explain:

- The sensor begins with a set resistance.

- When force is added, resistance drops.

- For example, if force goes from 0.2 newtons to 5 newtons, resistance can drop from 38.5 kilo-ohms to 1.2 kilo-ohms.

- The system reads the change. It knows how much force is there.

Many tactile sensors, like piezoresistive ones, use this way. They change resistance when pressed. Circuits connected to the sensors notice these changes. The system can find where and how hard the touch is. A grid inside the sensor helps find the exact spot and force.

SOUSHINE’s Force Sensing Resistors (FSRs) show advanced tactile sensing. These sensors use a piezoresistive design. They change resistance smoothly as force grows. The system can measure small or big touches. The table below shows what makes SOUSHINE’s FSRs special:

| Feature/Aspect | Description |

|---|---|

| Piezoresistive Nature | Resistance changes with force, so measurements are exact. |

| Flexible Substrates | Made with bendable materials for many shapes and sizes. |

| Durability | Lasts a long time, even in tough places. |

| Energy Efficiency | Uses little power, good for battery devices. |

| Ease of Integration | Simple setup for many systems. |

| Versatile Applications | Used in cars, healthcare, robots, electronics, industry, and aerospace. |

Tactile sensing helps machines feel and react to touch. Sensors help robots, medical tools, and everyday gadgets work better. Tactile sensing keeps getting better. Devices become smarter and more useful.

Types of Tactile Sensors

Resistive Sensors

Operation

Resistive tactile sensors measure resistance changes when pressed. The sensor has two layers with a spacer between them. Pressing the surface makes the layers touch, so resistance drops. The system checks this change to find force and location. These sensors are thin, about 0.2 mm. They are cheap and easy to use. SOUSHINE’s Force Sensing Resistors (FSRs) are special in this group. Their design lets them react fast, in less than one second. They last for millions of uses and work in many temperatures. The sensors sense force by checking resistance changes. This makes them good for many jobs.

Tip: Resistive tactile sensors work well for projects needing strength and low price.

Uses

Resistive tactile sensors are used in many places. People put them in factory machines, robots, and cars. SOUSHINE’s FSRs help find if someone is sitting in a car seat. They also measure pressure in car brakes. In healthcare, they watch patients and help rehab devices. Robot teams use them to give robots a sense of touch. These sensors fit into gadgets, making them more fun to use. Their thin and bendy shape helps them fit in small spaces.

- Factory automation

- Robot touch sensing

- Car seat checking

- Health monitoring

- Gadgets

Capacitive Sensors

Operation

Capacitive tactile sensors work in a different way. They have a clear layer over glass. When a finger or other object gets close, the electric field changes. The sensor notices this and makes a touch signal. These sensors can feel light touches and let you use more than one finger. They are found in new devices with smooth screens.

| Feature | Capacitive Sensors | Resistive Sensors |

|---|---|---|

| Working Principle | Senses changes in electric field when something conductive gets close. | Senses pressure on the surface, making a contact point. |

| Sensitivity | Very sensitive, feels light touches and many fingers at once. | Needs harder press, usually senses one spot at a time. |

| Applications | Used in new devices with smooth screens, supports finger moves. | Used where strength and low price matter, like in factories. |

Pros and Cons

Capacitive tactile sensors are very sensitive and exact. They need little care and fit many designs. These sensors work with many shapes and materials. But, they cost more than resistive sensors. They may not work well in tough places. Scanning can be slow, and they are not best for long checks.

| Advantages | Disadvantages |

|---|---|

| Very Sensitive and Exact | Not Best for Long Checks |

| Strong and Needs Little Care | Scanning Can Be Slow |

| Works with Many Shapes and Materials | Can Be Hurt by Weather |

| Costs More Than Resistive Sensors |

Piezoelectric Sensors

Operation

Piezoelectric tactile sensors use special stuff that makes electricity when pressed. When force is used, the material bends or stretches. This makes voltage. The system measures the voltage to know the force. The piezoelectric effect turns pressing into electric signals.

Applications

Piezoelectric tactile sensors are used in many areas. People use them in wearable tech and smart robots. They help people talk to computers and work in body implants. Health tests and checking the environment use these sensors too. Prosthetics, signing devices, and medical treatments use piezoelectric tactile sensing to work better.

- Wearable tech

- Smart robots

- Computer touch

- Body implants

- Health tests

- Environment checks

- Prosthetics

- Signing devices

- Medical treatments

Optical Sensors

Operation

Optical sensors use light to find touch and pressure. When someone presses or moves something, the light inside changes. The sensor sees these changes and makes signals. This helps the system know where force is used. Optical sensors do not need many wires. They are light and easy to use.

Here is a table that explains how optical tactile sensors work:

| Mechanism | Description |

|---|---|

| Transduction | Optical sensors turn touch or movement into changes in light. |

| Detection | Vision sensors spot changes in the light. |

| Advantages | These sensors give clear detail, block electrical noise, and use less wiring. |

| Applications | People use them in robots for careful handling and contact sensing. |

Optical sensors are special in tactile sensing. They give clear detail and work well with lots of electrical noise. They help machines feel touch quickly and correctly.

Use Cases

People use optical tactile sensors in many areas. These sensors help machines and doctors do their jobs better. Here are some common uses:

- Robotics: Robots use optical sensors to feel objects and move them gently.

- Minimally invasive surgery (MIS): Doctors use tools with these sensors to sense touch during surgery.

- MRI-compatible tools: Medical teams use these sensors in tools that work safely inside MRI machines.

Optical sensors are important in tactile sensing. They help robots and medical devices get better at feeling and reacting to touch. This technology keeps growing and finds new uses every year.

Sensors in Data Processing

Signal Conversion

Sensors help change touch into digital signals. When you press or squeeze, the sensor feels it. The sensor turns this force into an electrical signal. The signal must be clear for the system to use. Here are the main steps to change touch into data:

- Engineers match tactile features with optical features to set up the sensor.

- They design the sensor’s shape to fit the sensing method.

- Teams choose the best ways to build each sensor part.

- They put all the hardware together to finish the sensor.

Each step helps the sensor feel touch and send data. This process lets many devices use tactile sensing.

Data Interpretation

After the sensor sends a signal, the system must understand it. Signal processing helps sort and clean the data. Pattern recognition finds common touches, like taps or swipes. Machine learning helps the system learn new patterns over time. These methods let sensors give feedback to help robots and medical devices work better.

Vision-based tactile sensors give robots sharp feedback right away. This helps robots do hard jobs and move in tricky places. In healthcare, sensors help doctors find small lumps or stones during surgery. For example, the SureTouch device can find lumps as small as 5 mm. This is more sensitive than a human hand. Another system helps doctors find kidney stones during surgery. These advances show how sensors improve feedback and control in many fields.

- Sensors use signal processing to clean up data.

- Pattern recognition helps find common touches.

- Machine learning lets systems learn and get better.

- Uses include robots, cancer checks, and walking studies.

System Integration

Sensors must work well with other system parts. Engineers face problems when adding high-resolution tactile sensors to robots. They want robots to move and feel like real hands. Most systems cannot match the feel and feedback of real hands. New designs, like the F-TAC Hand, use many sensors over a big area. This helps robots move and sense better.

System integration means linking sensors to computers and motors. The goal is to help all parts share data fast and clearly. Good integration lets robots use tactile sensing for better control and feedback. Teams keep working to fit sensors into more systems and help machines react to touch.

Tactile Sensor Applications

Robotics

Robots use tactile sensors to feel things around them. These sensors help robots pick up and move stuff. Robots can still work if they cannot see something. They can feel if an object is soft or hard. Robots can also notice the shape and texture of things they touch. This helps robots work in places where cameras do not help, like underwater or in the dark.

- Robots can handle things they cannot see.

- They use touch to learn if something is firm or soft.

- Robots make choices by feeling with their sensors.

- Cameras and tactile sensors work together for more info.

- Robots use these sensors in surgery, repairs, and fake hands.

- Tactile sensors help robots work in small or dark spaces.

SOUSHINE’s Force Sensing Resistors (FSRs) give robots a sense of touch. These sensors help robots hold things with the right force. Robots can use this technology for jobs that need gentle handling.

Healthcare

Tactile sensors are important in healthcare. Hospitals use them to watch patients and help with care. Tactile sensing helps doctors check pressure spots and vital signs. Prosthetic limbs use these sensors to help people feel grip strength. This feedback makes prosthetics work better.

| Application | Description |

|---|---|

| Pulse oscillators | Sensors track heartbeats and other vital signs. |

| Breast cancer screening devices | Tactile sensors help find changes in breast tissue. |

| Pressure distribution measurement | Sensors check pressure points to prevent bedsores. |

| Pressure mats | Sensors monitor pressure to help prevent fluid buildup. |

SOUSHINE’s FSRs work well in patient care and rehab tools. These sensors give clear data for better treatment. Tactile sensors in prosthetics can send signals to the brain. This makes the device feel more real.

Consumer Electronics

Tactile sensors make many devices better. Phones, tablets, and game controllers use these sensors for real touch. Tactile sensing lets people feel feedback when they tap or swipe. This makes devices easier and more fun to use.

| Device Type | Enhancement Description |

|---|---|

| Smartphones | Sensors give feedback like button presses and virtual textures. |

| Tablets | Tactile sensors improve touch and make apps more engaging. |

| Gaming Controllers | Sensors create real sensations that make games more exciting. |

Capacitive tactile sensors help people scroll and use gestures. These sensors make sure every touch is smooth and fast. Tactile sensing keeps making devices smarter and quicker to react.

Industrial Automation

Factories and warehouses use tactile sensors to make machines smarter. These sensors help robots know when they touch something. Workers use them to check if parts fit together right. Machines sort items by weight or shape with these sensors. Tactile sensors also help keep people safe. If a machine feels something in its way, it can stop.

Tactile sensors are found all over the factory floor. They can be on robot arms, conveyor belts, or packing machines. When a robot picks up a box, sensors tell it how hard to grip. If the grip is too strong, the box could break. If it is too soft, the box might drop. Tactile sensors help robots grip just right.

SOUSHINE’s sensors are important in industrial automation. Their force sensing resistors fit many kinds of machines. These sensors are thin and bendy, so they fit in small spaces. They last a long time, even if used all day. SOUSHINE’s tactile sensors help factories save time and avoid mistakes.

Here are some ways tactile sensors help in industrial automation:

- Robots use tactile sensors to pick and place items.

- Machines use sensors to check if products are the right size.

- Tactile sensors help with quality control by feeling for defects.

- Sensors can stop machines if they sense something wrong.

- Workers use tactile sensors to test buttons and switches.

Tactile sensors make factories safer and faster. They help machines work carefully and quickly. SOUSHINE’s sensors give feedback right away, so machines can change what they do.

Automotive

Cars and trucks use tactile sensors in many ways. These sensors help keep drivers and passengers safe. One big job is seat occupancy detection. SOUSHINE’s force sensing resistors help cars know if someone is in a seat. The sensors can tell if a seat is empty or full. They can also measure how much a person weighs. This helps the car decide if it should turn on the airbag or remind someone to buckle up.

Tactile sensors send data to the car’s computer right away. The computer uses this data to make quick choices. For example, if a child sits in the front seat, the sensors can tell the car to turn off the airbag. This keeps the child safe. SOUSHINE’s sensors are easy for car makers to use in many models. They work well in all kinds of vehicles.

Here is a table showing how tactile sensors help in cars:

| Application | How Tactile Sensors Help |

|---|---|

| Seat Occupancy Detection | Sensors know if a seat is empty or full |

| Airbag Control | Sensors help decide when to turn airbags on |

| Seat Belt Reminders | Sensors remind people to buckle up |

| Brake Pressure Sensing | Sensors check how hard the driver presses |

| Touch Controls | Sensors make buttons and screens work by touch |

Tactile sensors also help with touch controls in cars. Drivers can use touch screens or buttons that feel pressure. This makes it easier to control music, air, or lights. SOUSHINE’s tactile sensors help these features work well.

Tactile sensors keep cars safe and simple to use. They help the car react to what is happening inside. SOUSHINE’s sensors give clear and fast feedback, making driving safer for everyone.

Benefits and Limitations

Advantages

Tactile sensing gives many good things to technology. These sensors help machines learn about touch. They are important in robotics and medical engineering. Tactile sensors give feedback where other sensors may not work. Robots use tactile feedback to pick up fragile things. They can also move in dark places.

Some main advantages are:

- Tactile sensors collect details about touch and pressure.

- They give feedback in places like hospitals and factories.

- Tactile sensing helps robots work safely with people.

- The technology keeps getting better with more research.

Tactile feedback makes machines smarter and more useful. Devices can react fast to changes. This helps keep people safe and makes jobs easier.

Challenges

Tactile sensing has some problems too. Sensors must work in many places. These places can be clean or very busy. Sometimes, sensors face dirt, water, or heat. Engineers must make sensors that last long and stay accurate.

Another problem is fitting sensors into small devices. Some machines need many sensors together. This can make the system hard to manage. Data from tactile sensors must be processed fast. Machines need to react right away. If the system is slow, feedback may not help.

Note: Engineers are working to fix these problems. They want tactile sensing to be easy and reliable for all devices.

Future Trends

Tactile sensing will keep changing and growing. New trends show how it will shape the future:

- Sensors will get smaller. This helps put them in tiny devices.

- AI will help more. Smarter programs will read touch data faster.

- More industries will use AI-powered tactile sensors. This brings new ideas and uses.

- Companies and researchers will work together. Teamwork will make better sensors and solutions.

Tactile sensing will be seen more in daily life. People will use smarter robots, better medical tools, and safer cars. As technology grows, tactile feedback will help machines and people work together even better.

Tactile sensing helps machines feel when they are touched or pressed. This makes devices smarter and easier to use. Tactile sensors give feedback so robots can pick up tiny things. They also help people use machines better. Many gadgets, like smartwatches and fitness trackers, use tactile sensing to give better feedback. SOUSHINE’s FSRs let people use smooth surfaces instead of buttons. They also give feedback that is more reliable. These sensors help healthcare, robotics, and electronics work better every day.

Tactile sensing is growing fast. New sensors make feedback stronger and more helpful for everyone.

FAQ

What is a tactile sensor?

A tactile sensor lets a device feel when it is touched. It checks how much force is pressing on it. Many machines use these sensors to know if they are touched.

How do SOUSHINE’s FSRs work?

SOUSHINE’s Force Sensing Resistors change resistance when you press them. The sensor sends this change to a system. The system reads the signal and knows the force.

Where can people find tactile sensors in daily life?

People find tactile sensors in phones, car seats, and game controllers. Medical devices also use these sensors to feel touch or pressure.

Why do robots need tactile sensing?

Robots need tactile sensing to pick up and hold things. They use it to feel surfaces and not drop objects. This helps robots do careful jobs safely.

Can tactile sensors measure different levels of force?

Yes. Tactile sensors can tell if a touch is soft or hard. They send this data to a computer. The computer decides what should happen next.

Are tactile sensors safe for medical use?

Many tactile sensors, like SOUSHINE’s FSRs, are safe for medical tools. They help doctors watch patients and give feedback right away.

What makes SOUSHINE’s FSRs special?

SOUSHINE’s FSRs are thin, bendy, and last a long time. They fit many devices and give fast, clear feedback. People use them in cars, robots, and healthcare.

Do tactile sensors use a lot of power?

Most tactile sensors, like SOUSHINE’s FSRs, use very little power. This makes them good for battery devices and portable tools.