Call us: +86-137-2353-4866

Choosing the right pressure sensor depends on what you need. Picture a technician working in a busy factory. They need to check force sensing. There are many types of pressure sensors to pick from, including vacuum, piezoelectric, and sealed models. Understanding these types helps them make informed decisions. Readers should consider their environment, look at the pressure range, and choose the output they want before learning more.

Table of Contents

Key Takeaways

- Learn about the seven main types of pressure sensors. These are absolute, gauge, differential, sealed, piezoresistive, capacitive, and optical.

- Pick a pressure sensor that fits your needs. Think about where you will use it and the pressure range.

- Absolute pressure sensors give true pressure readings. They use a vacuum as a reference. These sensors work well for barometric and medical uses.

- Gauge pressure sensors measure pressure compared to air pressure. They are good for cars and HVAC systems.

- Differential pressure sensors check pressure differences. They are important for HVAC and filtration systems.

- Sealed pressure sensors stay accurate when outside pressure changes. They are best for factories and airplanes.

- Piezoresistive sensors are very sensitive. They help with exact pressure checks in cars and healthcare.

- Capacitive sensors work well for touch controls in electronics. They are very sensitive and stay stable for a long time.

Types of Pressure Sensors

Overview

Engineers and technicians use different pressure sensors in many places. Each sensor type is best for certain jobs. Knowing about these types helps people pick the right one.

The seven main types of pressure sensors are:

- Absolute Pressure Sensors

- Gauge Pressure Sensors

- Differential Pressure Sensors

- Sealed Pressure Sensors

- Piezoresistive Pressure Sensors

- Capacitive Pressure Sensors

- Optical Pressure Sensors

Each type works in its own way to find pressure. Some sensors check pressure using a vacuum. Others compare two pressures. Many businesses use these sensors for safety and control.

Tip: Learning about pressure sensors can help people avoid expensive mistakes.

Comparison Table

The table below shows the main types of pressure sensors. It points out how they work and where they are used.

| Type of Sensor | Measurement Principle | Application Context |

|---|---|---|

| Absolute Pressure Sensors | Measure pressure relative to a perfect vacuum | Barometric pressure, vacuum systems |

| Gauge Pressure Sensors | Measure pressure relative to atmospheric pressure | Tire pressure, HVAC systems |

| Differential Pressure Sensors | Measure the difference between two pressures | Flow measurement, filter monitoring |

| Sealed Pressure Sensors | Reference a fixed pressure instead of a vacuum | Environments with fixed reference pressure |

| Piezoresistive Sensors | Use strain gauges to measure diaphragm deformation | Industrial automation, medical devices |

| Capacitive Pressure Sensors | Measure changes in capacitance due to diaphragm movement | Consumer electronics, automotive |

| Optical Pressure Sensors | Detect pressure changes through light variations | High-precision scientific instruments |

Many businesses use these pressure sensors. For example, cars often use gauge and capacitive sensors. Medical tools need piezoresistive sensors for good results. Science labs may pick optical sensors for very careful work.

Choosing a pressure sensor depends on where it will be used. It also depends on how exact it needs to be. Some sensors are better for tough places. Others are best for careful measuring. The table helps people find the right sensor.

Note: Picking the right sensor makes systems work better and last longer.

Pressure sensors keep getting better as technology grows. New designs and materials make them stronger and easier to use. People should learn about new sensors to get the best results.

Absolute Pressure Sensors

Principle

Absolute pressure sensors use a perfect vacuum as their reference. This means they measure the total atmospheric pressure. Other sensors use air around them as a reference. Absolute pressure sensors give a true pressure reading. This helps people get correct data when air pressure changes.

Note: Using a vacuum as a reference gives steady and trustworthy results.

Applications

Many industries need absolute pressure sensors for important jobs. These sensors help control and watch systems that need exact pressure.

- Barometric Pressure Monitoring: Weather stations use these sensors to check air pressure.

- Altitude Sensing: Planes and cars use them to find height by checking pressure.

- Vacuum Control: Factories and labs use these sensors to watch vacuum systems.

- Medical Devices: Blood pressure monitors and breathing machines need correct pressure readings.

- Industrial Process Control: Machines and pipes use these sensors to keep things working right.

Features

Absolute pressure sensors have special features that make them different. The table below shows how they compare to other sensor types.

| Feature | Piezoresistive | Capacitive | Piezoelectric |

|---|---|---|---|

| Response Speed | Fast | Moderate | Slow |

| Sensitivity to Pressure Change | High | Moderate | High |

| Common Usage | MAP Sensors | General Pressure Sensing | Dynamic Pressure Sensing |

These sensors are very accurate and steady. They work well even when things change. Their design makes them good for science and industry.

Gauge Pressure Sensors

Principle

Gauge pressure sensors check pressure compared to the air around them. They use a simple formula:

The sensor looks at the pressure of air or liquid. It compares this to the current air pressure outside. This way, people see if the pressure is higher or lower than the air nearby. Many jobs use this method because it is easy to understand and use.

Tip: Gauge pressure sensors help people watch systems where air pressure changes can change how things work.

Applications

Gauge pressure sensors are important in many jobs. They give quick pressure readings that help in factories and hospitals. People use them in:

- Chemical plants

- Oil and gas places

- Medicine making

- Food factories

- HVAC systems

They also help with:

- Car brakes

- Car engines

- Safety systems

- Breathing machines

- Special air chambers

- Breathing tests

- Drug machines

- Factory controls

These uses show that gauge pressure sensors can do many things. They help keep people safe, make work better, and help products stay good in many fields.

Features

Gauge pressure sensors have features for hard jobs. Makers build them to last in tough places and give good results. Some main features are:

- Ceramic pressure sensors: These sensors fight chemicals, stand heat, and take sudden pressure jumps. They work well in hard factory jobs.

- Sapphire pressure sensors: These sensors are very hard and fight chemicals. They work in very hot places and can handle up to 400°C.

Here is a table that shows the main features:

| Sensor Type | Chemical Resistance | Temperature Tolerance | Durability | Suitable Environments |

|---|---|---|---|---|

| Ceramic | High | High | Excellent | Industrial, chemical plants |

| Sapphire | Very High | Very High (up to 400°C) | Exceptional | Extreme, high-temperature |

Note: Picking the right sensor material helps sensors last long and stay safe in hard places.

Gauge pressure sensors give correct, quick data. Their strong build and ability to change make them a top pick for many jobs.

Differential Pressure Sensors

Principle

Differential pressure sensors check the pressure at two places. The sensor has a thin, bendable diaphragm inside. This diaphragm splits the sensor into two chambers. Each chamber gets pressure from a different spot. When the pressure changes, the diaphragm bends. This bending changes resistance or capacitance. The sensor turns this change into an electric signal. The signal shows the difference in pressure. The diaphragm is made from strong and flexible materials. It can bend many times without breaking.

- A bendable diaphragm splits the sensor into two parts.

- Each part gets pressure from a different place.

- The diaphragm bends when pressure changes.

- The sensor turns this bending into an electric signal.

- The signal tells the difference in pressure.

Applications

Differential pressure sensors are used in many jobs. HVAC systems use them to check air pressure across filters. This helps keep air moving and shows when filters need changing. The sensors also help control pumps and air systems. They save energy and make buildings more comfortable. Filtration systems use these sensors to find pressure drops from dirt. This helps change filters on time and keeps air clean.

| Application Area | Description |

|---|---|

| Air Conditioning | Checks pressure across filters to show when to change them, keeping air moving and clean. |

| Ventilation Systems | Watches air pressure inside and outside to change air flow for fresh air. |

| Heating Systems | Follows pressure in heating pipes for good heat and flow. |

| Commercial Buildings | Helps save energy and money by watching pressure well. |

- Checks air pressure across filters.

- Shows when filters need changing.

- Helps control pumps and air systems.

- Works with smart building tech for quick changes.

Features

Differential pressure sensors have features that help them work well. The diaphragm is built to bend and measure pressure right. The sensor gives fast data for system checks. It works with air and liquids. The design lets it connect to automatic systems. The sensor keeps working in tough places.

Tip: Checking systems often with differential pressure sensors stops problems and saves money.

- Measures pressure differences correctly.

- Gives fast data for system control.

- Works with many types of media.

- Strong diaphragm lasts a long time.

- Connects easily to automatic systems.

Sealed Pressure Sensors

Principle

Sealed pressure sensors use a set pressure inside. The sensor has a diaphragm that moves when gas or liquid pushes it. First, the gas or liquid pushes on the diaphragm. Next, the diaphragm bends from the pressure. Sensing parts notice this bending and change how they work. Then, the electronics turn this change into a normal signal. The signal goes to a screen or control system. This helps people watch the pressure. This way, sealed pressure sensors give good readings even if the outside changes.

Applications

Sealed pressure sensors are used in many fields. They help keep things safe and make systems work better. The table below shows where they are used:

| Industry | Purpose of Use |

|---|---|

| HVAC Systems | Reliable pressure monitoring for safety and efficiency |

| Automotive Manufacturing | Accurate pressure measurement for system performance |

| Aerospace Engineering | Ensures safety and reliability in flight systems |

| Medical Equipment Development | Critical for maintaining safety in medical devices |

| Industrial Process Control | Improves efficiency and long-term performance |

Engineers use these sensors where outside pressure changes a lot. They also use them in systems that need a set reference to measure right.

Features

Sealed pressure sensors have features that make them tough and steady in hard places. The table below lists the main features:

| Feature | Description |

|---|---|

| Robust construction | Fully welded stainless steel construction ensures durability and reliability. |

| Hermetically sealed | Protects against EMI and RFI, important for aerospace applications. |

| Compatibility with media | Works with different gases and liquids, increasing versatility. |

These features help sealed pressure sensors last longer and work well in rough spots. Engineers pick them for jobs that need strong and steady sensors.

Piezoresistive Pressure Sensors

Principle

Piezoresistive pressure sensors find force changes by checking resistance. The sensor has three layers. The middle layer is a piezoresistive material. Makers often use graphene in a PDMS mix for this. The way the resistive parts are set up makes signals stronger. This is most true where the strain is highest. When you press on the sensor, the resistance or paths for electricity change. Tiny structures on the base help these paths work better. This gives the sensor high sensitivity and quick response. Special designs with small structures make the sensor more sensitive. They also let it sense a wide range of pressures.

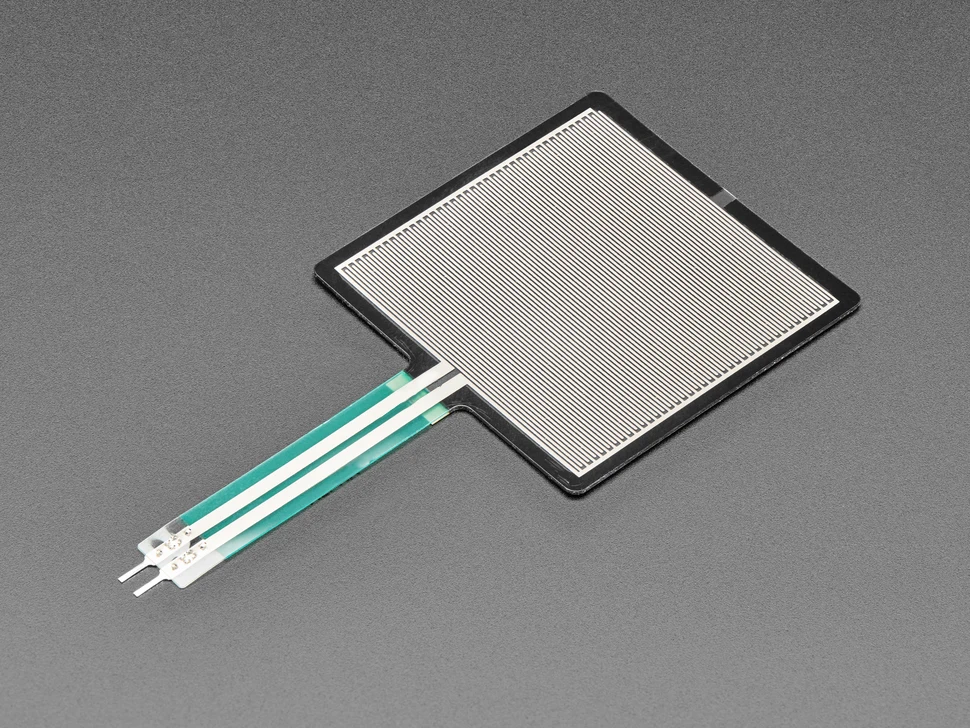

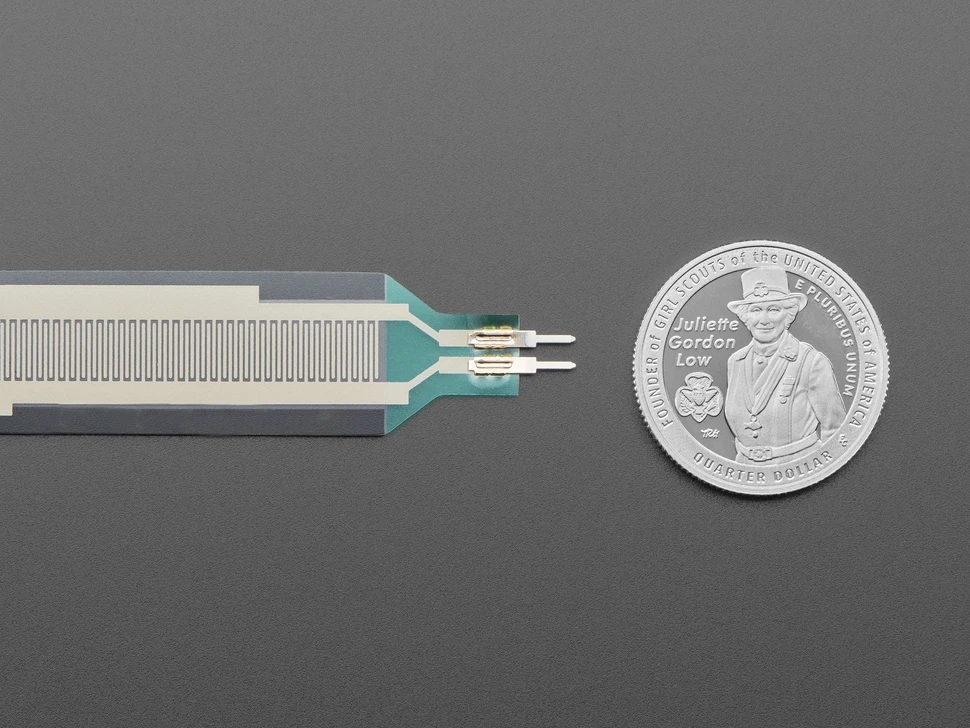

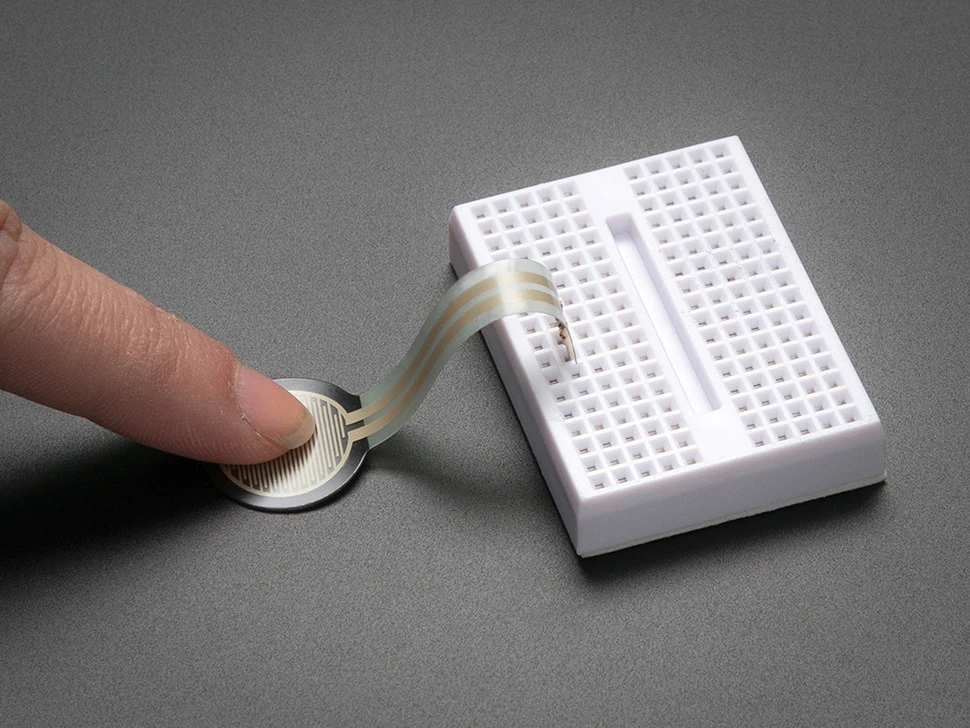

SOUSHINE’s Force Sensing Resistors use advanced piezoresistive technology. These FSRs have a bendable base, a spacer, and a layer that conducts electricity. This setup lets the sensor measure force and pressure all the time. It does not just give on or off signals.

Engineers like piezoresistive sensors because they turn force into steady electrical signals.

Applications

Piezoresistive pressure sensors are used in many fields. They are helpful in cars, healthcare, robots, and electronics.

- Car engineers use them to watch manifold absolute pressure. This helps control fuel and spark timing.

- Tire Pressure Monitoring Systems use these sensors to check tire pressure. This keeps cars safe and saves fuel.

- Braking systems use them to watch brake fluid pressure. This helps brakes work well.

- Electric and hybrid cars use these sensors for cooling and high-voltage parts.

- Automation and self-driving systems use them for cruise control and avoiding crashes.

- Healthcare workers use these sensors in patient monitors and rehab tools.

- Robots use these sensors to feel touch. This helps robots interact with things around them.

- Electronics for people use these sensors for touch screens and buttons.

SOUSHINE’s FSRs can be made in many shapes and sizes. This helps them fit special needs in different jobs.

Features

SOUSHINE’s Force Sensing Resistors have many good points compared to other piezoresistive sensors. The table below shows the main features:

| Feature | SOUSHINE’s FSRs | Other Piezoresistive Sensors |

|---|---|---|

| Customizable Shapes and Sizes | Yes | Limited |

| Durability and Reliability | High | Varies |

| Low Power Consumption | Yes | Often higher |

| Ease of Integration | Simple electrical interface | May require complex setup |

SOUSHINE lets people pick custom options so sensors fit their projects. The FSRs are strong and last a long time, even in tough places. They use little power, which is good for saving energy. They are easy to add to new devices, so projects move fast.

SOUSHINE helps customers from the start to the end, making sure their sensors work for each project.

Capacitive Pressure Sensors

Principle

Capacitive pressure sensors find pressure by checking capacitance changes. The sensor has two metal plates with a layer between them. When you press on the sensor, the plates move closer together. This makes the capacitance go up. The sensor checks this new capacitance to know the pressure. An oscillator connects to one plate inside. When something pushes on the sensor, capacitance rises. The oscillator makes a bigger signal, which sends out an output. The sensor gathers electric charges based on how hard you press. This helps measure pressure correctly.

Capacitive sensors react fast to touch and pressure. They are used in lots of devices.

Applications

Capacitive pressure sensors are used in many places. Electronics use these sensors for touch controls. They take the place of regular buttons and switches. Phones, tablets, and remotes use them for volume and power. They also help with menu controls. These sensors give feedback you can feel. They make using devices easy. The sensors notice different force levels. This helps people use devices better.

- Touch buttons on phones and tablets

- Volume and power controls in electronics

- Menu controls in smart appliances

- Medical devices for watching patients

- Car systems for seat and climate control

- Factory machines for process control

Capacitive sensors help designers make new products with fewer moving parts. They last longer and break less.

Features

Capacitive pressure sensors have many good features for different jobs. They are very sensitive and can find small pressure changes. Hot or cold temperatures do not change how they work much. The sensors stay accurate for a long time. They can measure both high and low pressures.

| Feature | Description |

|---|---|

| High Sensitivity | Finds small pressure changes |

| Minimal Temperature Effect | Stays accurate in hot or cold |

| Long-Term Stability | Works well for a long time |

| Wide Pressure Range | Measures high and low pressures |

Engineers pick capacitive sensors because they work well and measure small pressures.

Capacitive pressure sensors help make modern products work better. Their features make them a good choice for many uses.

Optical Pressure Sensors

Principle

Optical pressure sensors use light to check pressure changes. Inside the sensor, there is an LED and a measuring diode. A diaphragm moves when the pressure changes. This movement pushes a vane. The vane controls how much infrared light reaches the measuring diode. The sensor sees these light changes and turns them into pressure readings. The design lets the sensor measure pressure without touching the medium.

Optical sensors give correct data by watching tiny movements with light.

Applications

Optical pressure sensors are used in medical and research jobs. They can measure things without touching them. This is important in sensitive places.

- Non-invasive medical tests

- Wearable sensors for checking glucose

- Watching heart rate, breathing, and blood pressure in real time

- Measuring electrolyte levels and pH in body fluids

Researchers use these sensors to study fluids and gases. Hospitals use them to watch patients. Labs use them to follow chemical reactions and changes in the environment.

Features

Optical pressure sensors have special features that make them different from other sensors.

| Feature | Description |

|---|---|

| High Sensitivity | Finds small pressure changes with light |

| Non-contact Operation | Checks pressure without touching the medium |

| Immunity to EMI | Not bothered by electromagnetic interference |

| Fast Response | Gives quick readings |

| Long-term Stability | Stays accurate for a long time |

Engineers pick optical sensors for jobs that need clean and steady data. These sensors work well where electrical noise can cause problems. Their non-contact design stops contamination and wear.

Optical pressure sensors help keep medical and science work safe and correct.

Choosing a Pressure Sensor

Key Factors

Picking the right pressure sensor takes a few steps. Each step helps you find the best sensor for your job.

Pressure Range

Engineers need to know the highest and normal pressures in the system. The sensor should cover at least 80% of the top pressure. In hydraulic systems, the sensor’s range should be 1.5 times the highest pressure. Keeping the working pressure between 50% and 80% of the sensor’s range helps it work well and last longer.

- Sensors control hydraulic fluid pressure for safety.

- Picking the right range stops overload and sensor damage.

Environment

Where you use the sensor changes how it works and lasts. Outdoor and factory places need sensors that handle heat, cold, wetness, and dirt. Waterproofing and UV shields are needed outside. Chemical plants need sensors that don’t rust.

- Check the temperature and humidity.

- Look for dust, water, or chemicals nearby.

- Pick sensors with the right protection.

Output Type

The output signal must fit the system’s needs. Some systems use analog signals. Others use digital outputs. The right match helps everything work together.

- Analog outputs give steady readings.

- Digital outputs give exact data for machines.

Accuracy

Accuracy depends on what you need. Lab work needs sensors with very small errors. Factory machines may not need perfect accuracy.

- Decide how accurate you need the sensor to be.

- More accuracy usually costs more money.

Budget

Money matters when picking a sensor. Think about the price and how much it costs to keep working. Strong sensors cost more but need less fixing and replacing.

- Balance price and what you need the sensor to do.

- Think about setup and future repairs.

Decision Checklist

A checklist helps you pick the right pressure sensor for your job. The table below shows each step to follow.

| Step | Description |

|---|---|

| 1 | List what the sensor will measure and the conditions. |

| 2 | Check how accurate and fast the sensor needs to be. |

| 3 | Choose materials that won’t rust or break. |

| 4 | Make sure the sensor is safe for the area. |

| 5 | Check if the sensor can talk to your system. |

| 6 | Look at all costs, not just the first price. |

| 7 | Work with a supplier who knows sensors well. |

Tip: Using a checklist helps you avoid mistakes and pick the best sensor.

Example Scenarios and Recommendations

- Scenario 1: An engineer needs a sensor for a hydraulic press in a factory. The system works at 100 bar and sometimes goes up to 120 bar. The engineer picks a sensor with a 150 bar range, analog output, and a strong steel case.

- Scenario 2: A technician puts a sensor outside to watch water pressure. The sensor must handle rain, sun, and changing temperatures. The technician picks a waterproof, UV-safe sensor with digital output for remote checks.

- Scenario 3: A medical device designer needs very exact pressure readings for a patient monitor. The designer picks a high-accuracy sensor with a digital output and checks that it meets medical safety rules.

Note: Picking a sensor with the right features helps it work well and last a long time.

Picking the right pressure sensor helps systems work better and stay safe. Engineers need to think about what they need. They should ask experts for help with hard projects. SOUSHINE gives help and makes special sensors for different needs.

Talk to SOUSHINE to learn how the best sensor can help your project work well and last a long time.

FAQ

What is the difference between a pressure transducer and a pressure transmitter?

A pressure transducer changes pressure into an electrical signal. A pressure transmitter sends this signal far away for control or monitoring. Engineers use transmitters in places that are not close by. Transducers are used for measuring pressure nearby.

How do vacuum pressure sensors work?

Vacuum pressure sensors check pressure lower than the air around us. They have a chamber inside with a vacuum. The sensor finds changes in pressure and sends this data to control systems in labs or factories.

Can multivariable pressure sensors measure more than one parameter?

Multivariable pressure sensors check pressure and other things like temperature or flow. These sensors help engineers watch over complicated systems. They make factories work better and help control processes.

Where are piezoresistive pressure sensors commonly used?

Piezoresistive pressure sensors are used in cars, healthcare, and robots. They give correct force and pressure readings. Makers put them in patient monitors, touch devices, and car safety systems.

What factors affect the accuracy of a pressure sensor?

How accurate a sensor is depends on calibration, keeping temperature steady, and good materials. Engineers pick very accurate sensors for lab work. They use less exact ones for regular factory jobs.

How do engineers choose the right pressure sensor for harsh environments?

Engineers pick sensors that are strong and have special coatings. They think about temperature, wetness, and chemicals. Stainless steel and sapphire sensors work well in tough places.

Are pressure sensors easy to integrate into existing systems?

Most pressure sensors have standard electrical connections. Engineers hook them up to control units or data loggers. Makers help with setting up and fixing problems.

Can pressure sensors be customized for specific applications?

Makers can change the shape, size, and output type of sensors. Engineers ask for special sensors for cars, medical tools, or factory machines.